Descascador de amendoim | Máquina combinada de descasque e limpeza de amendoim

Como uma das principais culturas oleaginosas do mundo, o amendoim é cultivado em muitos países. E a área de plantação é grande. E o cultivo em grande escala significa muito trabalho e tempo. Com o desenvolvimento contínuo da tecnologia, o descascador de amendoim tornou-se um ajudante para a agricultura dos agricultores. O uso de descascadores de amendoim melhora muito a eficiência do trabalho. E descascado muito limpo. E existem diferentes modelos de unidades de descascar amendoim agora. Diferentes modelos têm diferentes rendimentos. Além dos descascadores de amendoim, colheitadeiras de amendoim e colhedoras de amendoim também são bons ajudantes para a agricultura diária das pessoas.

O que é uma máquina combinada de descascar e limpar amendoim?

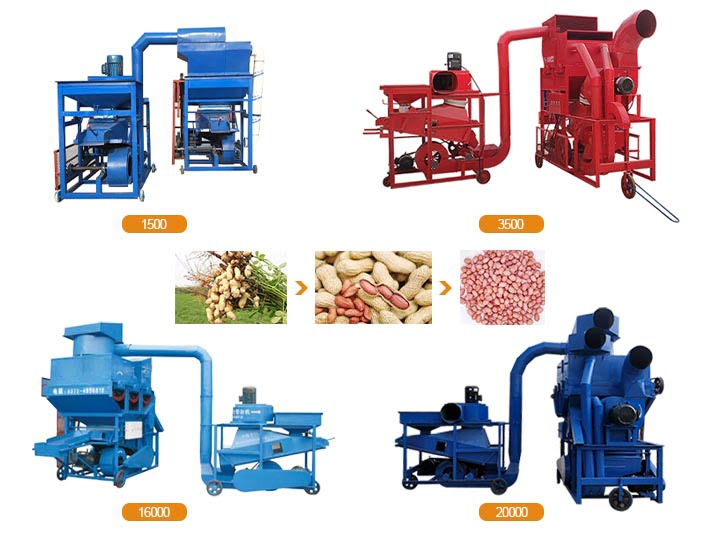

Uma máquina combinada de descascar e limpar amendoim é um equipamento que separa cascas e grãos de amendoim. Em geral, a unidade de descascamento de amendoim inclui uma máquina de limpeza. A máquina de limpeza é um dispositivo que remove antecipadamente as impurezas do amendoim sem casca. As impurezas geralmente são torrões, pedras, mudas de amendoim e folhas. A produção da unidade de descascamento de amendoim é geralmente relativamente grande. Temos quatro modelos de 6BHX-1500, 6BHX-3500, 6BHX-16000 e 6BHX-20000. Cada modelo lida com volumes diferentes. Os clientes podem escolher o modelo de máquina que mais lhes convém de acordo com suas necessidades.

Tipo 1: descascador de amendoim combinado 6BHX-1500

Em geral, a máquina combinada de descascar e limpar amendoim 6BHX-1500 funciona com o limpador. O produto final é muito mais limpo. E é benéfico prolongar a vida útil da máquina descascadora. Cada descascador de amendoim possui uma tela, e existem telas com diferentes tamanhos de malha. Portanto, para recomendar telas adequadas aos clientes, eles são obrigados a medir a largura do corpo dos amendoins. Em circunstâncias normais, a malha da tela é de 7/8/9/11 mm. Este modelo de descascador de amendoim requer a instalação de duas telas. A potência deste modelo é um motor elétrico. Este modelo de máquina é o menor comparado a outros modelos. Portanto, a máquina de descascar amendoim é pequena e leve.

Parâmetro técnico do descascador e limpador de amendoim

| Capacidade (kg/h) | Taxa de bombardeio % | Taxa de quebra % | Taxa de perda |

| 700-800 | >=99 | <=5 | <=0,5 |

| Umidade de trabalho % | Potência do motor | Peso (kg) | Tamanho da máquina |

| 6,3<=12 | Nível 2 1,5 kW / nível 4 3 kW | 520 | 1500*1050*1460 |

Tipo 2: Descascador e limpador de amendoim combinado 6BHX-3500

A máquina combinada de descascar e limpar amendoim 6BHX-3500 é semelhante em estrutura ao modelo 1500. Para a máquina de limpeza, o cliente pode escolher livremente de acordo com suas necessidades. Este modelo de máquina pode ser equipado com três telas. O tamanho da tela precisa ser determinado de acordo com o tamanho do amendoim do cliente. A produção deste tipo de máquina é maior que a do tipo 1500. A potência da máquina também é o motor.

Especificações técnicas da máquina de debulhar amendoim

| Capacidade (kg/h) | Taxa de bombardeio % | Taxa de quebra % | Taxa de perda |

| 1500-2200 | >=99 | <=5 | <=0,5 |

| Umidade de trabalho % | Potência do motor | Peso (kg) | Tamanho da máquina |

| 6,3<=12 | 2 níveis 4kw / 6 níveis 5,5 kw | 1000 | 2500*1200*2450 |

Tipo 3: descascador de amendoim 6BHX-16000

A máquina combinada de descascar e limpar amendoim 6BHX-16000 é o equipamento cuja produção pode chegar a 2.500-3.500 kg por hora. Mais amendoins podem ser processados de uma só vez. Este modelo pode ser equipado com três ou quatro telas. Como o tamanho de cada tela é diferente, é conveniente descascar amendoins de tamanhos diferentes e descascar de forma mais limpa. Além disso, pode reduzir a taxa de esmagamento do amendoim. A potência da máquina para este modelo ainda é o motor.

Parâmetro do descascador de amendoim 6BHX-16000

| Capacidade (kg/h) | Taxa de bombardeio % | Taxa de quebra % | Taxa de perda |

| 2500-3500 | >=99 | <=5 | <=0,5 |

| Umidade de trabalho % | Potência do motor | Peso (kg) | Tamanho da máquina |

| 6,3<=12 | 2 níveis 11 kW / 6 níveis 11 kw/ 6 níveis 4 kw | 2300 | 2650*1690*3360 |

Tipo 4: máquina debulhadora de amendoim 6BHX-20000

A máquina combinada de descascar e limpar amendoim 6BHX-20000 é a maior máquina combinada de descascar amendoim. A estrutura deste modelo é basicamente a mesma da descascadora de amendoim 6BHX-16000. Instale duas ou quatro telas. Cada parte da máquina é acionada por um motor. O último grão de amendoim é basicamente isento de impurezas porque, no processo de descascamento, existe um ventilador para extrair a casca e as impurezas do amendoim.

Qual é a especificação do descascador de amendoim de grande produção 6BHX-20000

| Capacidade (kg/h) | Taxa de bombardeio % | Taxa de quebra % | Taxa de perda |

| 5000-8000 | >=99 | <=5 | <=0,5 |

| Umidade de trabalho % | Potência do motor | Peso (kg) | Tamanho da máquina |

| 6,3<=12 | 2 níveis 15 kW / 6 níveis 15 kw/ 6 níveis 4 kw | 2850 | 2750*1800*3360 |

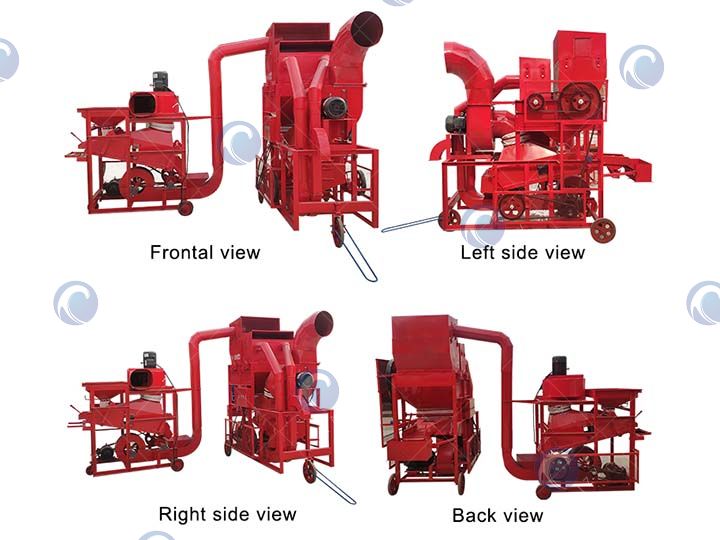

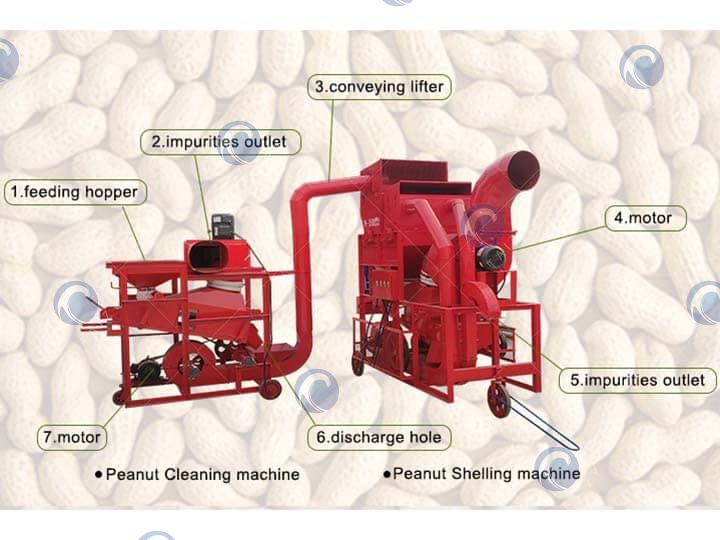

Que tal a estrutura da descascadora automática de amendoim?

Os quatro modelos de máquinas combinadas para descascar e limpar amendoim são semelhantes em estrutura. Inclui principalmente saída de amendoim limpo, entrada de amendoim, saída de impurezas, motor, elevador de transporte, caixa de tela fechada, saída de grãos de amendoim, caixa de tela fechada, rodas universais, etc.

O processo de trabalho do descascador de amendoim

1. Primeiramente, coloque o amendoim no reservatório de alimentação da máquina de limpeza. E a máquina de limpeza removerá sujeira, pedras, poeira de folhas de amendoim e outras impurezas.

2. Em segundo lugar, o amendoim entrará na máquina de descascar amendoim, através do elevador.

3. Em terceiro lugar, o descascador de amendoim irá descascar o amendoim através da combinação de uma caixa de tela fechada e um ventilador especial.

4. Finalmente, após selecionar e descascar cuidadosamente, os grãos de amendoim saem do orifício de descarga.

Diferenças entre os quatro descascadores de amendoim combinados

1. Diferentes modelos têm diferentes números de telas. O 1500 tem duas telas, o 3500 tem três telas e o 16.000 e o 20.000 têm três ou quatro telas. Quanto maior o número de peneiras, maior será a taxa de decapagem e menor será a taxa de britagem.

2. A produção da máquina combinada de descascar e limpar amendoim é diferente. Quanto maior o modelo do descascador de amendoim, maior será o rendimento.

3. A estrutura combinada da máquina de descascar e limpar amendoim de diferentes modelos será ligeiramente diferente.

4. O tamanho do motor descascador de amendoim é diferente para cada modelo.

Características da máquina de remoção de casca de amendoim

- A máquina de remoção de casca de amendoim adota principalmente o método de descasque por rolo. Este método garante um desempenho estável e fiável do descascador de amendoim e uma longa vida útil.

- Esta máquina combinada de descasque e limpeza de amendoim também possui um bom efeito de descasque e alta produtividade. Os amendoins que saem do exportador estão basicamente livres de impurezas.

- Baixa taxa de perda e pequena taxa de quebra. Adequado para processar amendoins de diversas especificações.