เครื่องปลูกพืช | เครื่องปลูกผักแบบขับเคลื่อนด้วยตนเอง

| แบบอย่าง | 2ZBLZ-4 |

| ประเภทโครงสร้าง | ซอฟต์แวร์รวบรวมข้อมูลขับเคลื่อนด้วยตนเอง |

| น้ำหนักเครื่อง | 970กก |

| อำนาจสนับสนุน | 4.05kw |

| จำนวนแถวการทำงาน | 4 แถว |

| ความเร็วในการทำงาน | 0.8-1.5 กม./ชม |

เครื่องปลูกพืชสามารถปลูกต้นกล้าผักต่างๆ เช่น หัวหอม มะเขือเทศ และผักกาดหอม ได้อย่างแม่นยำและมีประสิทธิภาพ ดังนั้นการใช้เครื่องปลูกจึงสามารถช่วยให้เกษตรกรประหยัดเวลาและพลังงานได้มาก

เรามีสามรุ่น: แบบขับเคลื่อนในตัว, แบบตีนตะขาบ และแบบขับเคลื่อนด้วยรถแทรกเตอร์ ผู้ย้ายปลูกของเราสามารถย้ายจากแถวขั้นต่ำสองแถวไปจนถึงสูงสุดสิบสองแถวพร้อมกันได้ นอกจากนี้ เรายังปรับแต่งแถวและระยะห่างของโรงงานเพื่อรองรับความต้องการเฉพาะของลูกค้าของเราได้ดียิ่งขึ้น

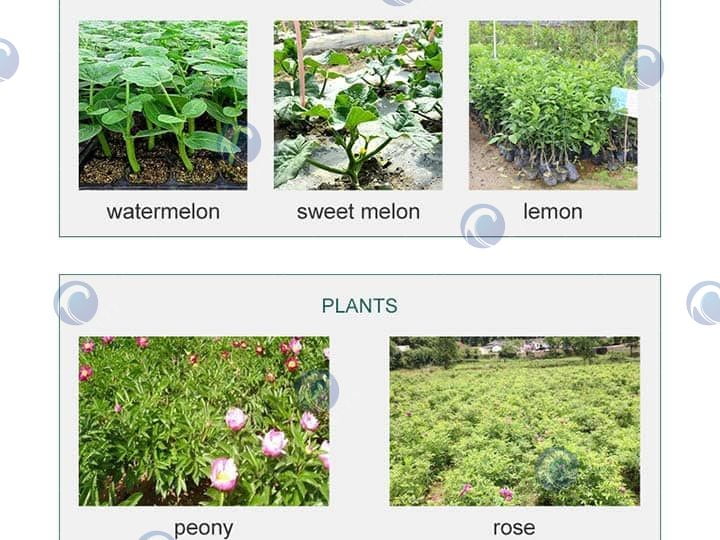

ผู้ปลูกต้นกล้าสามารถปลูกเมล็ดพันธุ์อะไรได้บ้าง?

เครื่องย้ายปลูกสามารถปลูกพืชได้หลากหลาย เช่น มะเขือเทศ พริกไทย คื่นฉ่าย หัวหอม ผักทารก บรอกโคลี กะหล่ำปลี แครอท ผักชี ป่าน ยาสูบ ฟักทอง ถั่วเขียว และฟีนูกรีก และอื่นๆ อีกมากมาย

เครื่องปลูกต้นกล้ามีความหลากหลายและสามารถรองรับต้นกล้าได้หลายประเภท ตามความต้องการเฉพาะของลูกค้าของเรา เราขอแนะนำเครื่องจักรที่เหมาะสมซึ่งปรับให้เหมาะกับความต้องการด้านพืชผลเฉพาะของลูกค้า

ตอนนี้เราเข้าใจแล้วว่าเมล็ดพืชชนิดใดที่สามารถปลูกได้ มาดูประเภทต่างๆ ของเครื่องปลูกผักที่มีจำหน่ายกัน

เครื่องปลูกผักขาย

เครื่องปลูกผักของเราได้รับการออกแบบมาเพื่อตอบสนองความต้องการของทั้งแปลงขนาดเล็กและฟาร์มขนาดใหญ่ โดยมีความแม่นยำในการปลูกสูงและช่วยเพิ่มประสิทธิภาพและคุณภาพของผลผลิตอย่างมาก เรามีรุ่นต่างๆ รวมถึงเครื่องปลูกแบบขับเคลื่อนด้วยตนเอง แบบล้อเลื่อน และแบบลากด้วยรถแทรกเตอร์ เพื่อให้เหมาะกับสภาพพื้นที่และสภาพการปลูกที่แตกต่างกัน.

เครื่องจักรที่ขับเคลื่อนด้วยตนเองและประเภทที่ลากได้มักจะใช้พลังงานจากเครื่องยนต์เบนซิน ในขณะที่รุ่นที่ลากจะทำงานร่วมกับรถแทรกเตอร์ รุ่นส่วนใหญ่ - ยกเว้นประเภทล้อที่ขับเคลื่อนด้วยตนเองพื้นฐาน - สามารถติดตั้งฟังก์ชันเพิ่มเติม เช่น การไถพรวนแบบหมุน การใส่ปุ๋ย การรดน้ำ การคลุมดิน การทำแปลง การปลูกถ่าย และแม้แต่การวางท่อระบายน้ำแบบหยด สิ่งนี้ทำให้เครื่องจักรเหล่านี้มีความหลากหลายสูงและสามารถทำงานหลายอย่างในครั้งเดียวได้.

ไม่ว่าคุณจะทำงานในพื้นที่เกษตรกรรมราบหรือพื้นที่ลาดเอียง เครื่องปลูกต้นกล้าอัตโนมัติเหล่านี้ให้โซลูชันที่ยืดหยุ่นและมีประสิทธิภาพ พร้อมที่จะค้นหาตัวแบบที่เหมาะสมสำหรับพืชผลของคุณแล้วหรือยัง? สำรวจเครื่องปลูกผักของเราได้เลยวันนี้!

ประเภทที่หนึ่ง: เครื่องปลูกผักแบบขับเคลื่อนในตัว

เครื่องปลูกผักแบบขับเคลื่อนด้วยตนเองที่มีล้อเป็นเครื่องจักรที่กะทัดรัดและมีน้ำหนักเบาออกแบบมาเพื่อการปลูกต้นกล้าที่มีประสิทธิภาพและสะดวกสบาย ขับเคลื่อนด้วยเครื่องยนต์เบนซิน สามารถปลูกได้ทั้ง 2 หรือ 4 แถวพร้อมกัน ทำให้เหมาะสำหรับการทำฟาร์มผักขนาดเล็กถึงขนาดกลาง.

เพื่อรองรับความต้องการของพืชผลที่แตกต่างกัน ทั้งระยะห่างระหว่างแถวและระยะห่างระหว่างต้นสามารถปรับแต่งและปรับเปลี่ยนได้ภายในช่วงที่กำหนด เมื่อเปรียบเทียบกับเครื่องปลูกแบบอื่นๆ รุ่นนี้มีขนาดที่กะทัดรัดกว่าทำให้สามารถเคลื่อนย้ายได้ง่ายในสภาพพื้นที่ที่แคบ.

ด้วยการออกแบบที่ใช้งานง่ายและประสิทธิภาพที่เสถียร เครื่องปลูกผักแบบขับเคลื่อนด้วยตนเองนี้เป็นตัวเลือกที่ยอดเยี่ยมสำหรับการเพิ่มประสิทธิภาพในการปลูก ต่อไปเรามาดูโครงสร้างและส่วนประกอบหลักของมันกันอย่างใกล้ชิด.

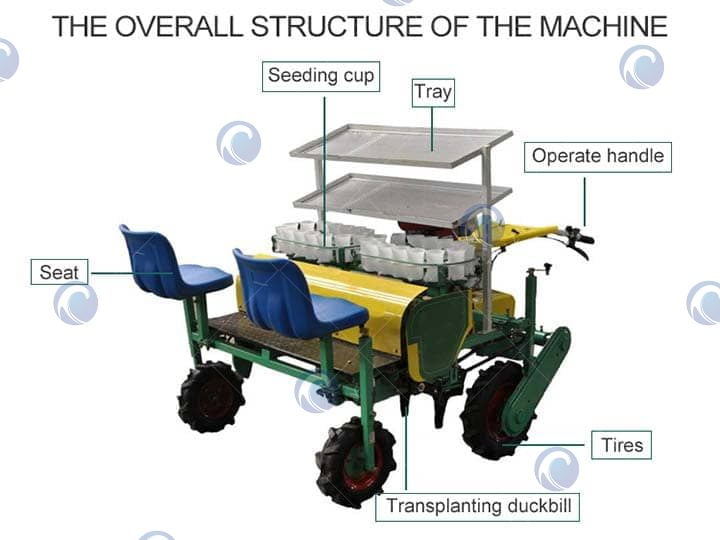

โครงสร้างของเครื่องปลูกถ่ายแบบขับเคลื่อนในตัว

เครื่องปลูกต้นกล้าขับเคลื่อนด้วยตนเองประกอบด้วยส่วนประกอบหลัก เช่น ระบบถ้วยต้นกล้า, ที่นั่งผู้ปฏิบัติงาน, ที่ถือถาดต้นกล้า, โครงสร้างที่แข็งแรง, กลไกการปลูก และล้อ. ขับเคลื่อนด้วยเครื่องยนต์เบนซิน, เครื่องจะเคลื่อนที่ไปข้างหน้าโดยอัตโนมัติ.

ในระหว่างการทำงาน คนงานนั่งอยู่บนที่นั่งและวางต้นกล้าจากถาดลงในถ้วยต้นกล้าโดยใช้มือ ถ้วยเหล่านี้จะถูกนำทางโดยกลไกการปลูกเพื่อใส่ต้นกล้าเข้าไปในดินอย่างแม่นยำ ทำให้การปลูกมีประสิทธิภาพและถูกต้อง

เครื่องทรานสมานเตอร์ทำงานอย่างไร?

พารามิเตอร์ทางเทคนิคของเครื่องปลูกพืชคืออะไร?

| แบบอย่าง | 2ZBZ-2 | 2ZBZ-4 |

| ระยะห่างของพืช | 200-500มม | 200-500มม |

| ระยะห่างระหว่างแถว | 300-500มม | 150-300มม |

| ความจุ | 1,000-1400 ตรม./ชม | 1,400-2,000 ตรม./ชม |

| แถว | 2 แถว | 4 แถว |

| พลัง | 4.05kw | 4.05kw |

ต่อไป เรามาสำรวจเครื่องปลูกถ่ายแบบตีนตะขาบซึ่งขึ้นชื่อเรื่องความเสถียรและประสิทธิภาพ

ประเภทที่สอง: เครื่องปลูกพืชชนิดตีนตะขาบ

เครื่องปลูกพืชแบบล้อเลื่อนเป็นเครื่องจักรที่มีความหลากหลาย สามารถปลูกพืชได้ 2, 4, 6, 8, 10 หรือแม้แต่ 12 แถวในการทำงานครั้งเดียว ทำให้เหมาะสำหรับการปลูกในขนาดใหญ่.

นอกจากการปลูกถ่ายแล้ว เครื่องจักรนี้ยังสามารถติดตั้งฟังก์ชันเสริมได้ เช่น การคลุมดินและการวางเทปน้ำหยด ทำให้เกษตรกรสามารถทำงานหลายอย่างได้พร้อมกัน.

เรายังมีบริการปรับแต่งเพื่อให้ตรงตามระยะห่างระหว่างแถว ฟังก์ชัน และความต้องการของพืชผล โดยมั่นใจว่าเครื่องจักรจะตรงตามความต้องการในการปลูกของลูกค้าแต่ละรายอย่างสมบูรณ์แบบ.

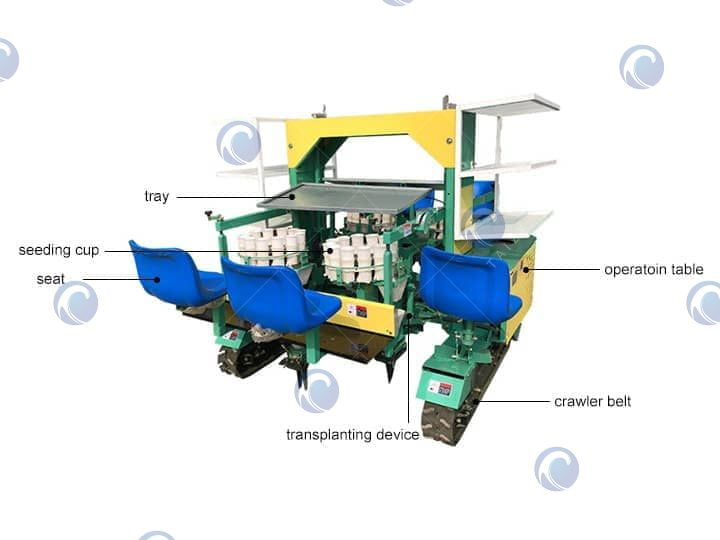

โครงสร้างเครื่องปลูกหัวหอมอัตโนมัติ

เมื่อเปรียบเทียบกับประเภทแรก เครื่องปลูกหัวหอมอัตโนมัตินี้มีโครงสร้างที่ซับซ้อนและทันสมัยกว่า มันถูกติดตั้งด้วยส่วนประกอบที่จำเป็น เช่น โครงสร้างที่แข็งแรง ที่นั่งผู้ปฏิบัติงาน ถ้วยกล้า ถาดรองกล้า กลไกการปลูก และรางเลื่อน พร้อมด้วยระบบปฏิบัติการที่รวมอยู่ด้วย.

นอกจากนี้ ยังสามารถติดตั้งระบบเสริมสำหรับการคลุมดินและการวางเทปให้น้ำแบบหยด ซึ่งช่วยให้สามารถทำงานหลายอย่างได้ในครั้งเดียว—ประหยัดทั้งเวลาและแรงงานในระหว่างกระบวนการปลูก

วีดีโอการทำงานของเครื่องปลูกต้นกล้าอัตโนมัติ

พารามิเตอร์เฉพาะของเครื่องปลูกพืชมีอะไรบ้าง?

| แบบอย่าง | 2ZBLZ-4 |

| ประเภทโครงสร้าง | ซอฟต์แวร์รวบรวมข้อมูลขับเคลื่อนด้วยตนเอง |

| น้ำหนักเครื่อง | 970กก |

| อำนาจสนับสนุน | 4.05kw |

| โหมดการส่งข้อมูล | สายพานขับ |

| จำนวนแถวการทำงาน | 4 แถว |

| ความเร็วในการทำงาน | 0.8-1.5 กม./ชม |

| ช่วงการปรับระยะห่างของพืช | 200-450มม |

| ช่วงการปรับความลึก | 60-120มม |

ความแตกต่างระหว่างประเภทที่หนึ่งและประเภทที่สอง

- เครื่องปลูกพืชประเภทที่หนึ่งใช้เฉพาะเครื่องยนต์เบนซิน ในขณะที่ประเภทที่สองรองรับทั้งเครื่องยนต์เบนซินและดีเซล.

- เครื่องปลูกพืชประเภทที่หนึ่งควบคุมโดยระบบแบบถือด้วยมือ ในขณะที่ประเภทที่สองทำงานผ่านแผงควบคุมที่ติดตั้งด้านข้าง.

- เครื่องปลูกพืชประเภทที่สองมีระยะห่างระหว่างแถวและระยะห่างระหว่างพืชที่กว้างกว่าประเภทที่หนึ่ง.

- เครื่องปลูกพืชประเภทที่หนึ่งไม่สามารถรองรับฟังก์ชันเพิ่มเติมได้ แต่ประเภทที่สองสามารถรวมฟังก์ชันการคลุมดินและการฝังสายพานให้น้ำหยด.

ประเภทที่สาม: รถปลูกผักที่ขับเคลื่อนด้วยรถแทรกเตอร์

รถปลูกผักที่ขับเคลื่อนด้วยรถแทรกเตอร์ใช้ PTO ในการส่งสัญญาณ ยิ่งไปกว่านั้น ยังมีฟังก์ชันเพิ่มเติมอีกมากมาย เช่น การปฏิสนธิ การขุดดิน การไถพรวนแบบหมุน การรดน้ำ การคลุมดิน การย้ายปลูก และการวางเทปให้น้ำหยด

คุณสมบัติเหล่านี้ทำให้มันมีความยืดหยุ่นสูงเพื่อตอบสนองความต้องการทางการเกษตรที่หลากหลาย เราขอแนะนำการรวมกันของเครื่องปลูกต้นกล้าที่เหมาะสมที่สุดตามความต้องการเฉพาะของลูกค้าเพื่อให้มั่นใจในประสิทธิภาพและประสิทธิผลสูงสุด.

สำหรับการดำเนินงานขนาดใหญ่ รถปลูกผักที่ขับเคลื่อนด้วยรถแทรกเตอร์ของเราคือตัวเลือกที่เหมาะสมที่สุด เรียนรู้เพิ่มเติมเกี่ยวกับเรื่องนี้ด้านล่าง เราจะเริ่มต้นด้วยส่วนประกอบหลัก

ส่วนประกอบหลักของเครื่องปลูกพืชที่ขับเคลื่อนด้วยรถแทรกเตอร์มีอะไรบ้าง?

เครื่องปลูกต้นกล้าอัตโนมัติประเภทนี้มีถ้วยเพาะกล้า ที่นั่ง ถาด โครง และอุปกรณ์ย้ายกล้า บนโครงสร้างพื้นฐานของเครื่องเราสามารถเพิ่มฟังก์ชั่นเพิ่มเติมได้ตามความต้องการของลูกค้า

เครื่องปลูกผักมีคุณลักษณะอย่างไร?

| แบบอย่าง | 2ZBX-2 | 2ZBX-3 | 2ZBX-4 | 2ZBX-6 | 2ZBX-8 | 2ZBX-10 | 2ZBX-12 |

| ระยะห่างในการปลูก | 200-500มม | 200-500มม | 200-500มม | 100-400มม | 100-400มม | 100-400มม | 100-400มม |

| ระยะห่างระหว่างแถว | 250-500มม | 250-300มม | 250-300มม | 150-300มม | 150-300มม | 150-300มม | 150-300มม |

| ความจุ | 1,000-1700 ตรม./ชม | 1,000-2,000 ตรม./ชม | 1,000-2700 ตรม./ชม | 1,400-3,400 ตรม./ชม | 2,000-4,000 ตรม./ชม | 2,700-5400 ตรม./ชม | 3700-6700m²/ชม |

| แถว | 2 แถว | 4 แถว | 4 แถว | 6 แถว | 8 แถว | 10 แถว | 12 แถว |

| พลัง | >=30แรงม้า | >=30แรงม้า | >=50แรงม้า | >=60แรงม้า | >=60แรงม้า | >=60แรงม้า | >=60แรงม้า |

ตรวจสอบข้อมูลจำเพาะโดยละเอียดของเครื่องปลูกผักแบบขับเคลื่อนด้วยรถแทรกเตอร์ของเรา การทำความเข้าใจข้อกำหนดเฉพาะเหล่านี้เน้นให้เห็นถึงข้อดีของเครื่องปลูกถ่ายของเรา

ข้อดีของเครื่องปลูกต้นกล้าผักแบบรถแทรกเตอร์คืออะไร?

- เครื่องนี้มีประสิทธิภาพที่เชื่อถือได้และปรับได้ง่ายเนื่องจากอัตราส่วนการส่งผ่านที่แม่นยำ.

- มันช่วยให้ระยะห่างในการปลูกที่แม่นยำ ทำให้การปลูกมีความสม่ำเสมอมากขึ้น.

- ส่วนประกอบหลักทั้งหมดทำจากวัสดุที่มีความแข็งแรงสูง ทำให้มีอายุการใช้งานยาวนานและการทำงานที่เสถียร.

- มันช่วยลดความเข้มข้นของแรงงานอย่างมากและช่วยประหยัดค่าใช้จ่ายด้านแรงงาน.

- คุณภาพการปลูกได้รับการปรับปรุงอย่างมีนัยสำคัญ ทำให้ค่าใช้จ่ายในการผลิตโดยรวมลดลง.

- การเจริญเติบโตของต้นกล้าที่สม่ำเสมอช่วยให้การจัดการในสนามทำได้ง่ายและมีประสิทธิภาพมากขึ้น.

- มันเพิ่มผลผลิตและคุณภาพของพืชผล ส่งผลให้ผลตอบแทนทางเศรษฐกิจดีขึ้น.

- เครื่องจักรช่วยประหยัดทั้งเวลาและแรงงาน ทำให้มีประสิทธิภาพในการดำเนินงานสูง.

ลงทุนในผักของเรา ต้นกล้า ผู้ปลูกถ่าย

รถปลูกผักปลูกของเรามีฟังก์ชันการทำงานที่หลากหลายและมีประสิทธิภาพสูงเพื่อตอบสนองความต้องการทางการเกษตรที่หลากหลาย หากคุณสนใจผลิตภัณฑ์ของเรา โปรดติดต่อเราเพื่อขอข้อมูลเพิ่มเติมหรือขอใบเสนอราคา

Additionally, we recommend using our nursery seedling machine in conjunction with the vegetable seedling transplanter. This combination allows for efficient seedling cultivation before transplanting, ensuring a seamless process from nursery to field. We look forward to your inquiries and the opportunity to work with you!