জোয়ার, বাজরা, রেপসিডের জন্য শস্য মাড়াই মেশিন

| মডেল | 5TGQ-100A |

| শক্তি | 7.5-11kw বা 12-15hp |

| পিলিং হার | 99% |

| ক্ষমতা | 1000 কেজি/ঘণ্টা |

| ওজন | 300 কেজি |

| আকার | 1800*1000*2300 মিমি |

| প্যাকিং | 1800*800*1700 মিমি |

শস্য মাড়াই মেশিন হল বিশেষ সরঞ্জাম যা বিশেষভাবে বাজরা, ঝাল এবং রেপসিডের জন্য ডিজাইন করা হয়েছে। এটি মাড়াই দক্ষতা এবং পরিষ্কারের হার উভয় ক্ষেত্রেই উৎকৃষ্ট, এটি পেশাদার কৃষি ব্যবহারের জন্য অত্যন্ত উপযুক্ত করে তোলে। সর্বোচ্চ দক্ষতায় অপারেটিং, এটি বড় আকারের উৎপাদনের চাহিদা পূরণ করে।

তাছাড়া, আমরা শস্য মাড়াই মেশিনের তিনটি স্বতন্ত্র মডেল অফার করি, প্রতিটি আলাদা আউটপুট ক্ষমতার জন্য তৈরি। উল্লেখযোগ্যভাবে, আমাদের মেশিনগুলি 99% পর্যন্ত একটি ব্যতিক্রমী থ্রেসিং দক্ষতা অর্জন করে।

এই সোর্ঘাম থ্রেসারটি বিশেষভাবে সেই অঞ্চলের জন্য উপযুক্ত যেখানে জোরা, বাজরা এবং রেপসিড ব্যাপকভাবে চাষ করা হয়। এটি জনপ্রিয়তা অর্জন করেছে এবং নাইজেরিয়া, জাম্বিয়া, পাকিস্তান, কাজাখস্তান, তাজিকিস্তান এবং কেনিয়া সহ অনেক দেশে রপ্তানি করা হয়।

বিক্রির জন্য শস্য মাড়াই মেশিন

তাইজি দ্বারা প্রস্তুতকৃত তিন ধরণের শস্য মাড়াই মেশিন রয়েছে। প্রতিটি মডেলের জন্য ফলন পরিবর্তিত হয়। সবচেয়ে ছোট আউটপুট হল 400 কেজি/ঘন্টা, এবং সবচেয়ে বড় আউটপুট হল 1000 কেজি/ঘন্টা। গ্রাহকরা তাদের চাহিদা অনুযায়ী উপযুক্ত মেশিন মডেল চয়ন করতে পারেন.

যেহেতু একটি মেশিন তিনটি ধরণের উপকরণ প্রক্রিয়া করতে পারে, প্রতিটি সময় বিভিন্ন উপকরণ প্রক্রিয়াকরণের সময় সংশ্লিষ্ট স্ক্রিনটি প্রতিস্থাপন করতে হবে। সংশ্লিষ্ট পর্দার সময়মত প্রতিস্থাপন মেশিনের আরও দক্ষ কাজ এবং আরও ভাল কাজের প্রভাবের জন্য সহায়ক।

শক্তি বিষয়ে, আমাদের মেশিনে বৈদ্যুতিক মোটর ও ডিজেল ইঞ্জিন যোগ করা যাবে। এর মধ্যে ডিজেল ইঞ্জিন শক্তি-কম অঞ্চলগুলোর গ্রাহকদের জন্য সহজে ব্যবহারের উপযোগী। সর্গাম থ্রেশার ছাড়াও, আমাদের কাছে পেশাদার বড় স্কেলের ভুট্টা ছাল ছাড়ানোর মেশিন, বহু-ফাংশনাল থ্রেশার ইত্যাদি রয়েছে।

জর মাড়াই সম্পর্কে প্রাথমিক তথ্য বোঝার পর, আমরা বাজরা মাড়াই মেশিনের প্রয়োগের পরিসরে অনুসন্ধান করব।

বাজরা মাড়াই মেশিনের অ্যাপ্লিকেশন পরিসীমা

আমাদের শস্য মাড়াই যন্ত্রটি হ্যান্ডেল করতে পারে এমন মাত্র তিন ধরণের উপকরণ রয়েছে, জোরা, বাজরা এবং রেপসিড। পেশাদার সরঞ্জাম দ্বারা প্রক্রিয়াকৃত উপকরণগুলির একটি উচ্চ অপসারণের হার, কম ক্রাশিং রেট এবং ভাল মাড়াই প্রভাব রয়েছে। এটি জোয়ার, বাজরা এবং ধর্ষণের বীজ প্রক্রিয়াকরণের জন্য আদর্শ সরঞ্জাম।

এর পরে, এর কার্যকারিতা আরও ভালভাবে বোঝার জন্য সোরঘাম থ্রেসার মেশিনের প্রযুক্তিগত পরামিতিগুলির উপর বিস্তারিতভাবে নজর দেওয়া যাক।

সর্গাম থ্রেশার মেশিনের প্যারামিটার

| মডেল | 5TGQ-100A |

| শক্তি | 7.5-11kw বা 12-15hp |

| পিলিং হার | 99% |

| ক্ষমতা | 1000 কেজি/ঘণ্টা |

| ওজন | 300 কেজি |

| আকার | 1800*1000*2300 মিমি |

| প্যাকিং | 1800*800*1700 মিমি |

পরামিতিগুলি অনুসরণ করে, আমরা মুক্তা বাজরা থ্রেসারের গঠনটি পরীক্ষা করব যাতে এটির কাজ করার পদ্ধতিটি আরও ভালভাবে বোঝা যায়।

মুক্তা বাজরা মাড়াই এর গঠন কি?

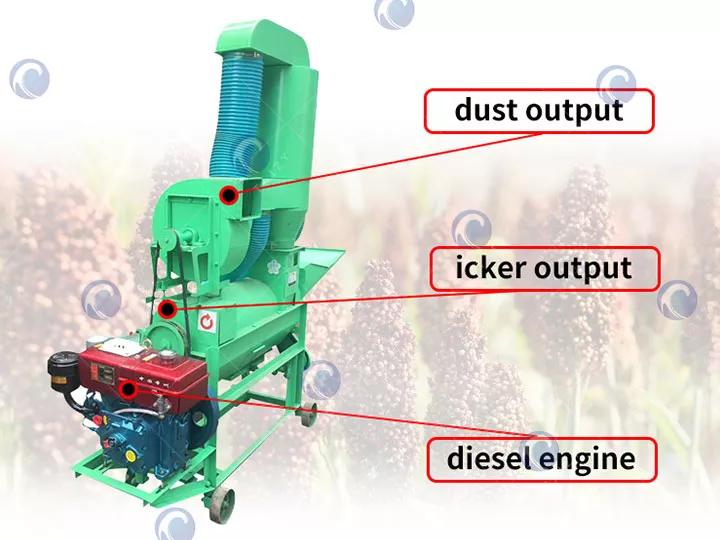

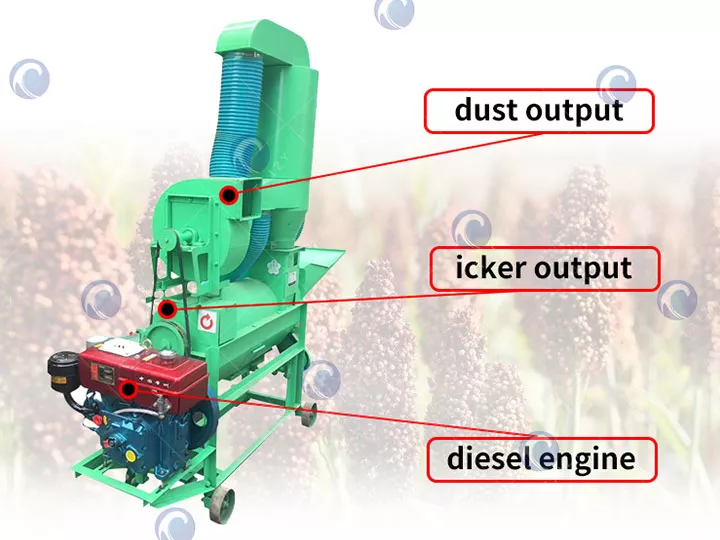

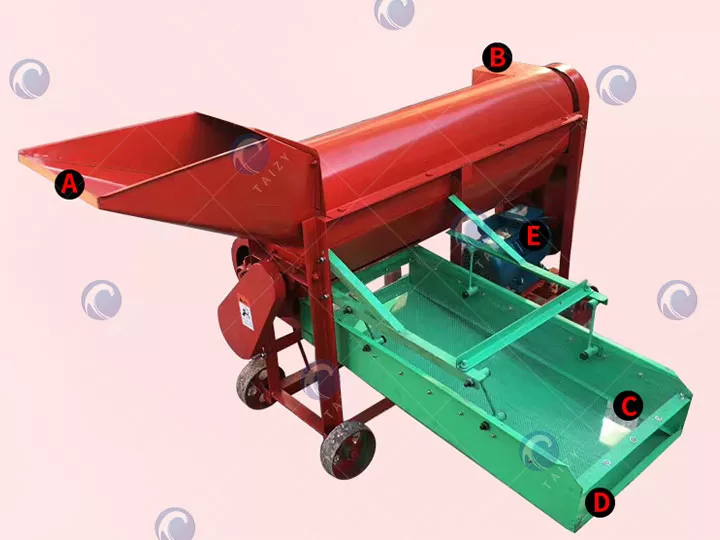

আমাদের কাছে তিনটি মডেলের শস্য মাড়াই মেশিন রয়েছে, 5TGQ-100A, এবং 5TGQ-100B এর চেহারা একই। 5TGQ-100C ভিন্ন।

তিনটি মেশিনের মধ্যে প্রধানত একটি ইনলেট, স্ক্রিন ম্যাশ, আউটলেট, ডাস্ট আউটপুট, আইকার আউটপুট এবং পাওয়ার অন্তর্ভুক্ত।

শস্য মাড়াই মেশিন কিভাবে কাজ করে?

এখন, শস্য মাড়াই মেশিনের বিশদ কার্য প্রক্রিয়ার মধ্য দিয়ে যাওয়া যাক।

খাওয়ানোর পর্যায়

শস্যের মাথাগুলিকে খাওয়ানোর প্ল্যাটফর্ম থেকে থ্রেসিং চেম্বারে সমানভাবে খাওয়ানো হয়।

মাড়াই এবং পৃথকীকরণ

থ্রেসিং চেম্বারের অভ্যন্তরে, শস্যগুলি অল্প পরিমাণে ভুসি এবং ধ্বংসাবশেষ থেকে পৃথক করা হয়, যা একটি অবতল প্লেটের মধ্য দিয়ে একটি আলোড়নকারী তুলোতে পড়ে।

ধ্বংসাবশেষ বিচ্ছেদ

আউগার শস্য এবং উপকরণগুলিকে একটি খড় স্তন্যপান যন্ত্রে নির্দেশ করে, যেখানে শস্যের ভুসিগুলির মতো অমেধ্যগুলিকে আলাদা করা হয় এবং একটি ছোট বায়ু পাইপের মাধ্যমে একটি উইনোয়ারে পাঠানো হয়।

ভারী অপবিত্রতা হ্যান্ডলিং

হালকা অমেধ্য এবং তুষ একটি পাখা দ্বারা বহিষ্কৃত হয়, যখন ভারী অমেধ্য দ্বিতীয় রাউন্ড মাড়াইয়ের জন্য থ্রেসিং চেম্বারে ফিরে আসে।

শস্য পরিষ্কার করা

পরিষ্কার করা দানাগুলি স্তন্যপান যন্ত্র থেকে প্রস্থান করে এবং একটি পরিষ্কার চালনীতে পড়ে। ছোট অমেধ্যগুলি চালনীর গর্তের মধ্য দিয়ে ফিল্টার হয়ে যায়, যখন দানা এবং বড় ধ্বংসাবশেষ চালনির পৃষ্ঠ বরাবর প্রস্থানের দিকে চলে যায়।

শস্য সংগ্রহ

দানাগুলি পরিষ্কার করার চালনীর আউটলেটের মধ্য দিয়ে বেরিয়ে যায় এবং শস্য সংগ্রহ ইউনিটে সংগ্রহ করা হয়।

খড় হ্যান্ডলিং

মাড়াই প্রক্রিয়া সম্পন্ন করে মাড়াই করা খড় একটি স্ট্র আউটলেটের মাধ্যমে নিষ্কাশন করা হয়।

এই পদক্ষেপগুলি নিশ্চিত করে যে শস্য মাড়াই মেশিন দক্ষতার সাথে শস্য আলাদা করে এবং পরিষ্কার করে, ক্ষতি কম করে এবং উচ্চ-মানের আউটপুট বজায় রাখে।

মেশিনটি কীভাবে কাজ করে তা বোঝার পরে, আসুন বাজরার শেলার মেশিনের সুবিধাগুলি দেখি।

বাজরা খোসা মেশিনের সুবিধা

- শস্য মাড়াই মেশিনের প্রক্রিয়াকরণ দক্ষতা বেশি। সোরঘাম থ্রেসার জরি অপসারণের কাজের দক্ষতাকে ব্যাপকভাবে উন্নত করে, যা ম্যানুয়াল সোর্ঘাম অপসারণের শতগুণ।

- থ্রেসার উচ্চ মানের এবং স্থিতিশীল কর্মক্ষমতা আছে. দৃঢ় ব্যবহারযোগ্যতার সাথে, ঝাল স্বয়ংক্রিয়ভাবে আলাদা হয়ে যায় এবং অপসারণের হার 99%-এ পৌঁছে।

- শস্য মাড়াই মেশিনে প্রক্রিয়াকরণের বিস্তৃত পরিসর রয়েছে এবং এটি বাজরা, জোরা এবং ধর্ষণের বীজের জন্য ব্যবহার করা যেতে পারে।

- মেশিনের গঠন সহজ, পরিচালনা করা সহজ এবং বজায় রাখা সহজ।

- সোরঘাম থ্রেসার 1-6 স্পাইক দানা মাড়াই, পরিষ্কার এবং আলাদা করতে পারে। তদুপরি, শস্য মাড়াই মেশিনে সহজ পরিষ্কার এবং হালকা চলাচলের সুবিধা রয়েছে।

এর পরে, আমরা একটি বাজরা থ্রেসারের একটি সফল কেস পর্যালোচনা করব যাতে এটি বাস্তব-বিশ্বের অ্যাপ্লিকেশনগুলিতে কীভাবে কাজ করে।

বাজরা থ্রেসারের একটি সফল কেস

নাইজেরিয়ার একটি বাজরা চাষ অঞ্চলে, একজন কৃষক আমাদের বাজরা থ্রেসার ব্যবহার করে ফসল কাটার দক্ষতায় উল্লেখযোগ্য উন্নতি অনুভব করেছেন।

এই থ্রেশারটি দ্রুত এবং কার্যকরভাবে খড় থেকে বাজরা আলাদা করে, তার জন্য শ্রম খরচ যথেষ্ট পরিমাণে হ্রাস করে। কৃষক উল্লেখ করেছেন যে থ্রেশার ব্যবহার করে সময় সাশ্রয় হয়, বাজরের উচ্চ গুণমান নিশ্চিত হয় এবং বিক্রির সময় প্রতিযোগিতা বৃদ্ধি পায়।

পরিশেষে, আসুন জেনে নেওয়া যাক কেন আপনি আমাদের সোর্ঘাম থ্রেসার মেশিন বেছে নেবেন।

কেন আমাদের ঝাল মাড়াই মেশিন বেছে নিন?

- আমরা কৃষি যন্ত্রপাতির পেশাদার প্রস্তুতকারক। দীর্ঘ সময়ের জন্য, আমরা উচ্চ মানের কৃষি যন্ত্রপাতি গবেষণা এবং উৎপাদনের জন্য প্রতিশ্রুতিবদ্ধ।

- উচ্চ মানের সরঞ্জাম। আমাদের উত্পাদন মেশিনগুলি উচ্চ-মানের, পরিধান-প্রতিরোধী উপকরণ দিয়ে তৈরি এবং মেশিনগুলির দীর্ঘ পরিষেবা জীবন রয়েছে।

- আমাদের পরিষেবাগুলি ব্যাপক। আমরা সবচেয়ে বিস্তৃত মেশিনের তথ্য প্রদান করব, গ্রাহকদের কাছে সবচেয়ে উপযুক্ত মেশিনের সুপারিশ করব, মেশিনটিকে কাঠের বাক্সে প্যাক করব এবং সময়মতো গ্রাহকদের লজিস্টিক তথ্য আপডেট করব।

- এক বছরের বিক্রয়োত্তর সেবা। গ্রাহক মেশিনটি পাওয়ার পর এক বছরের মধ্যে, অকৃত্রিম কারণে মেশিনটি ক্ষতিগ্রস্ত হলে আমরা তার জন্য দায়ী থাকব।

উপসংহার

শস্য ধান কুঁড়ানোর মেশিনে বিনিয়োগ করা মানে দক্ষতা, নির্ভরযোগ্যতা এবং উৎকৃষ্ট পারফর্ম্যান্স নির্বাচন করা। উন্নত প্রযুক্তি ও সূক্ষ্ম নকশার কারণে আমাদের মেশিন উচ্চমানের শস্য উৎপাদন এবং সর্বোচ্চ উৎপাদনশীলতা নিশ্চিত করে।

বিশ্বব্যাপী ক্রমবর্ধমান সংখ্যক সন্তুষ্ট গ্রাহকদের সাথে যোগ দিন যারা আমাদের অত্যাধুনিক যন্ত্রপাতির সাহায্যে তাদের কৃষি কার্যক্রমকে রূপান্তরিত করেছে। আপনার ফসল বাড়ানোর সুযোগটি হাতছাড়া করবেন না - আরও জানতে এবং আপনার অর্ডার দেওয়ার জন্য আজই আমাদের সাথে যোগাযোগ করুন!