コーングリッツ製造機丨小型トウモロコシグリッツ粉粉砕機

コーングリッツ製造機は、トウモロコシ粒全体をさまざまな粒度に加工できます。最終製品は通常、コーングリッツとコーンフラワーです。一般に、完成品のメッシュサイズは調整可能です。したがって、顧客は自分のニーズに応じて機械を調整して、適切なサイズのトウモロコシ粒を得ることができます。

トウモロコシ粉砕機は強力な機能を備えており、トウモロコシの洗浄、皮むき、胚芽除去、根除去、黒臍除去、破砕、グリット取り、選別、研磨などの一連の工程を一度に完了できます。

したがって、製造された完成したトウモロコシ粒は、色が明るく、きれいで、へその緒がありません。スーパーマーケットや穀物・石油卸売市場に直接参入することも可能です。さらに、 9FQ 様々な穀物を加工することができます。

当社のコーングリッツ製造機はどうでしょうか?

現在、当社ではコーングリッツ製造機のあらゆるモデルを取り揃えています。それぞれ T1、T3、PH、PD2、C2 です。機械のモデルが異なれば、機械の出力、出力、サイズ、構成も異なります。お客様はニーズに応じて適切な機械モデルを選択できます。

一般に、当社のトウモロコシ粉砕機は、大きなトウモロコシグリット、小さなトウモロコシグリット、コーンフラワーの 3 種類の最終製品を製造できます。

中でもPD2モデルは洗浄機とダブルエレベーターを追加可能です。このような機械の組み合わせによって製造される最終製品は、よりクリーンで生産性が高くなります。 T3型トウモロコシ粉砕機にはサイクロンが装備されており、トウモロコシのぬかを効果的に除去できます。

このように、各モデルにはそれぞれの特徴があります。トウモロコシを粉砕する前に、農家はトウモロコシの粒を入手する必要があります。効率的に作業するには、トウモロコシ脱穀機を使用するのが良い選択です。コーンシェルラーも多数取り揃えておりますので、お好みのものをお選びください。

タイプ 1: T1 コーングリッツ製粉機

T1 コーングリッツ製粉機の動力には、電気モーターまたはディーゼル エンジンを使用できます。このモデルのワークフローは、最初に皮を剥いてから、グリッツと小麦粉を作ることです。

トウモロコシの穀粒は、外皮を剥がされた後、大きな葉状の粒子となり、出口から排出されます。その後、お客様は粉砕部分を開け、皮を剥いたトウモロコシ粒を 2 番目の注入口に入れる必要があります。

そして機械はそれを 3 つの異なる形状の完成品に加工します。また、お客様の状況に応じて適切な電力を備えさせていただきます。

小型トウモロコシ粉粉砕機の仕様

| モデル | T1 |

| トウモロコシの皮むき | 350~450kg |

| コーングリッツを作る | 1000kg |

| 定格電圧 | 380v |

| 力 | 7.5kw 4極 |

| トウモロコシ粉を作る | 350kg |

| 主軸速度 | 1150r/分 |

タイプ 2: T3 トウモロコシグリッツ粉粉砕機

T3 コーングリッツ製造機は 2 つのモーターで駆動されます。機械のトウモロコシの皮むきとコーングリッツは同時に作業できます。ピーリングと砥石製造システムを同時に開始できます。したがって、作業効率も高くなります。

さらに、このモデルには除塵装置も装備されています。機械の作業過程で発生するトウモロコシのぬかや粉塵を回収・排出する装置です。したがって、最終製品もより清潔で衛生的です。

トウモロコシの皮むきとグリッツ粉砕機のパラメーターは何ですか?

| モデル | T3 |

| 力 | 7.5kw+4kw |

| 容量 | 300-400kg/h |

| サイズ | 1400*2300*1300mm |

| 重さ | 680kg |

T3 コーングリッツ製造機の利点

1. トウモロコシの皮むきとコーングリッツが同時にできます。剥離システムが作動するのを待ってから研削システムを開始します。人員を節約し、効率を向上させます。

2. コーングリッツ製造機にはサイクロンが装備されています。したがって、最終製品はよりクリーンで高品質になります。

タイプ 3: PH コーングリッツメーカー

このコーングリッツ製造機モデルは、T3 コーングリッツメーカーに似ています。違いは、この機械には塵埃除去装置がないことです。そのため、価格も比較的安いです。

設置面積が小さく、作業効率が高く、時間と労力を節約できるという特徴があります。ほとんどの顧客のニーズを満たすことができます。

農場用コーングリッツ製粉機の技術仕様

| モデル | PH |

| 容量 | 300(kg/h) |

| 力 | 11(kw) |

| サイズ | 200*130*65(cm) |

タイプ 4: C2 コーングリッツ粉粉砕機

C2 コーングリッツ粉粉砕機は、PH コーングリッツメーカーと同じように機能します。外観も似ていますが、いくつかの違いがあります。

しかし、この機械の価格は安いです。お客様のご予算に応じて最適な機械をお選びいただけます。

タイプ 5: PD2 トウモロコシ製粉機

このタイプのコーングリッツ製造機は、ダブルエレベーターとコーンピーリンググリッツ製造機で構成されるユニットです。具体的には、投入ホッパー、エレベーター、皮むき・粗粒化の3つの部分から構成されています。

加工プロセス全体は完全自動制御です。トウモロコシ製粉機は操作が簡単で、時間と労力を節約できます。また、洗浄機、搬送オーガー、穀物庫と組み合わせて、小型のコーングリッツ加工ラインを形成することもできます。

洗浄機は生の穀物からトウモロコシの穂軸、小石、カビを取り除きます。その後、洗浄された穀物はオーガによって穀倉に輸送されます。次に、エレベーターは生の穀物を処理機械に持ち上げて、皮をむき、粉砕し、粉砕します。

コーングリッツグラインダーの仕様は何ですか?

| モデル | PD2 |

| 力 | 15kw |

| 容量 | 400kg/h |

| サイズ | 265*125*320(cm) |

コーングリッツグラインダーの主なコンポーネント

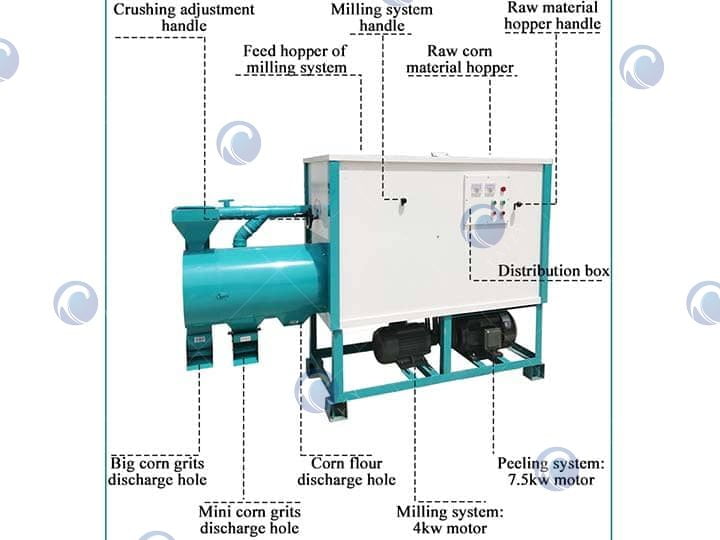

4 つのモデルの機械には、原料のトウモロコシ材料ホッパー、電気モーターまたはディーゼル モーター、皮むきシステム、製粉システム、ビッグ コーン グリッツ排出穴、ミニ コーン グリッツ排出穴、コーンフラワー排出穴などが含まれます。これらはすべて、機械の基本コンポーネントのモデルです。含まれています。機械の各モデルには独自の機能があります。

トウモロコシ粉砕機の作業フローは何ですか?

1. 原材料の紹介: コーングリッツ製造プロセスの開始

コーングリッツ製造機を作動させ、原料ホッパーにコーン粒を導入することから始めます。皮むきシステムは、これらのトウモロコシ粒をより小さな品種に変換します。

2. 粉砕システムの変革:トウモロコシの粒をさまざまな形に精製

粉砕システムに進むと、より小さいトウモロコシ粒が処理されます。粉砕システムが完了すると、トウモロコシ粒は、大きなコーングリット、小さなコーングリット、およびトウモロコシ粉の 3 つの異なる形状になります。

3. 製品の出荷: 3 つのアウトレットからの多様なトウモロコシ生産量

最終段階では、加工されたトウモロコシを 3 つの異なる形態 (大きなコーングリット、小さなコーングリット、およびコーンフラワー) で 3 つの別々の出口から排出します。

トウモロコシの利点 ピーラーとグラインダー

1. 操作が簡単で小型です。

2. 剥離と同時に風選と組み合わせることで、粒と種皮が分離され、破損率が大幅に低減されます。これにより、剥離品質と歩留まりがより効果的に向上します。

3. トウモロコシの硬い皮と胚芽部分を除去した後、トウモロコシの食味効果が向上し、トウモロコシの適用範囲が拡大します。

4. 皮をむいたトウモロコシ粉は、コーンヌードルの加工に直接使用できます。

5. 中小規模の穀物および米加工工場における小麦、米、トウモロコシ、ソルガム、その他の原料穀物の皮むき、破砕、空気選別、および微粉砕に適しています。

6. トウモロコシの皮むきとコーングリッツ製造機で加工された完成品は、スーパーマーケットや穀物と油の卸売市場に直接入ることができます。

お問い合わせ

最高品質の結果を保証する、信頼性が高く効率的なトウモロコシ加工ソリューションをお探しなら、当社のコーングリッツ製造機がその答えです。

当社の機械がお客様固有の加工ニーズにどのように対応できるかについては、今すぐお問い合わせください。最先端のテクノロジーと比類のない効率性であなたのビジネスを強化しましょう。