Corn grits making machine丨Small maize grits flour grinding machine

Corn grits making machines can process whole maize kernels into different particle sizes. The finished product is generally corn grits and cornflour. In general, the mesh size of the finished product is adjustable. Therefore, customers can adjust the machine according to their own needs to obtain a suitable size of corn kernels.

The maize grits making machine has powerful functions and can complete a series of processes such as cleaning, peeling, embryo removal, root removal, black navel removal, crushing, grit taking, grading, polishing, etc. on corn at one time.

So, the finished corn kernels produced are bright and clean in color and without an umbilical cord. And can be directly entered into supermarkets and grain and oil wholesale markets. Besides, we also have the 9FQ that can process various grains.

How about our corn grits making machine?

At present, we have a complete range of corn grits-making machine models. They are T1, T3, PH, PD2, and C2 respectively. Different models of machines vary in power, output of the machine, size, and configuration of the machine. Customers can choose the appropriate machine model according to their needs.

In general, our maize grinding machine can produce three kinds of finished products: large maize grits, small maize grits, and cornflour.

And among them, our PD2 model can add a cleaning machine and a double elevator. The finished product produced by such a machine combination is cleaner and more productive. The T3 type maize grits grinder is equipped with a cyclone, which can effectively remove the corn bran.

So, each model has its characteristics. Before grinding the corn farmers need to get corn kernels. And for efficient work, using a corn thresher is a good choice. We also have many kinds of corn shellers for your choice.

Type 1: T1 corn grits milling machine

The power of the T1 corn grits milling machine can be an electric motor or diesel engine. The workflow of this model is to peel the skin first and then make the grits and flour.

After the corn kernels are hulled, they become large lobed particles and are discharged through the outlet. After that, the customer must open the grinding part and put the dehulled corn kernels into the second inlet.

And then the machine will process it into three different forms of finished products. We will also be equipped with the appropriate power according to the specific situation of the customer.

Specification of the small maize flour grinding machine

| Model | T1 |

| Corn peeling | 350-450kg |

| Making corn grits | 1000kg |

| Rated voltage | 380v |

| Power | 7.5 kw 4 pole |

| Making corn flour | 350kg |

| Spindle speed | 1150r/min |

Type 2: T3 maize grits flour grinding machine

The T3 corn grits making machine is powered by two motors. The machine corn peeling and corn grits can work at the same time. We can start peeling and grit making systems at the same time. Therefore, the work efficiency is also higher.

In addition, this model of machine is also equipped with dust removal equipment. The equipment can collect and discharge the corn bran and dust generated during the working process of the machine. Therefore, the final product is also cleaner and hygienic.

What are the parameters of the corn peeling and grits grinding machine?

| Model | T3 |

| Power | 7.5 kw +4kw |

| Capacity | 300-400 kg/h |

| Size | 1400*2300*1300 mm |

| Weight | 680 kg |

Advantages of the T3 corn grits making machine

1. Corn peeling and corn grits can be done at the same time. We do not wait for the peeling system to work before starting the grinding system. Save manpower and improve efficiency.

2. The corn grits making machine is equipped with a cyclone. So the final product will be cleaner and of higher quality.

Type 3: PH corn grits maker

This corn grits making machine model is similar to the T3 Corn Grits Maker. The difference is that the machine has no dust removal device. So the price is relatively cheap.

It has the characteristics of a small footprint, high work efficiency, time-saving and labor-saving. Can meet the needs of most customers.

Technical specifications of the farm corn grits milling machine

| Model | PH |

| Capacity | 300(kg/h) |

| Power | 11(kw) |

| Size | 200*130*65(cm) |

Type 4: C2 corn grits flour grinding machine

The C2 corn grits flour grinding machine functions the same as the PH corn grits maker. They are also similar in appearance, with some differences.

But the price of this machine is lower. Customers can choose the machine that suits them according to their budget.

Type 5: PD2 maize milling machine

This type of corn grits making machine is a unit composed of a double elevator and a corn peeling grits making machine. Specifically, it consists of three parts: feeding hopper, elevator, and peeling and making grits.

The entire processing process is fully automatic control. The maize milling machine is easy to operate, saving time and effort. It can also be matched with a cleaning machine, conveying auger and granary to form a small corn grits processing line.

The cleaning machine will remove the corncob, stones, and mold from the raw grain. Then the cleaned grain is transported to the granary by the auger. Next, the elevator lifts the raw grain to the processing machine for peeling, crushing, and grinding.

What are the specifications of the corn grits grinder?

| Model | PD2 |

| Power | 15kw |

| Capacity | 400kg/h |

| Size | 265*125*320(cm) |

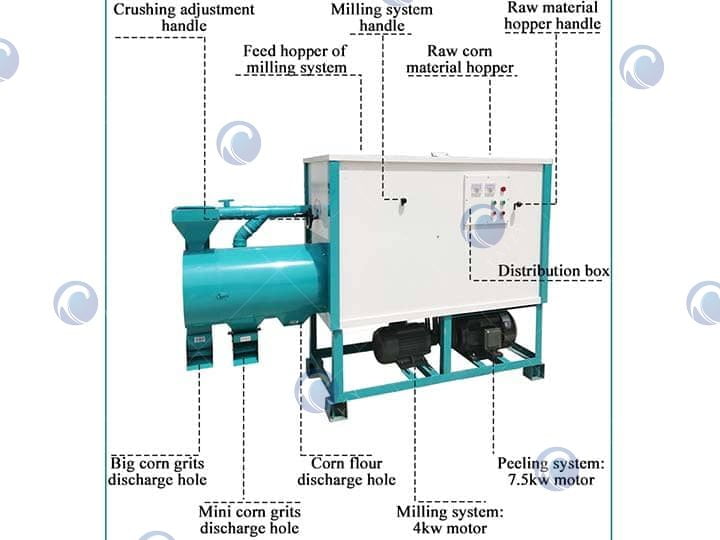

The main components of the corn grits grinder

The four model machines include a raw corn material hopper, electric motor or diesel motor, peeling system, milling system, big corn grits discharge hole, mini corn grits discharge hole, cornflour discharge hole, etc. These are all models of the machine’s basic components included. Each model of machine has its unique features.

What is the maize grits milling machine’s working flow?

1. Raw Material Introduction: Initiating the Corn Grits Making Process

Start by activating the corn grits making machine and introducing corn kernels into the raw material hopper. The peeling system transforms these corn kernels into smaller variants.

2. Grinding System Transformation: Refining Corn Kernels into Varied Forms

Progressing to the grinding system, the smaller corn kernels undergo processing. Upon completion of the grinding system, the corn kernels take on three distinct forms: large corn grits, small corn grits, and corn flour.

3. Product Discharge: Diversified Corn Output from Three Outlets

The final stage involves the discharge of the processed corn in three different forms—large corn grits, small corn grits, and corn flour—from three separate outlets.

Advantages of the maize peeler and grinder

1. Easy to operate and small in size.

2. The kernel and the seed coat are separated by combining with the wind selection at the same time of peeling, thus greatly reducing the breakage rate. This more effectively improves peeling quality and yield.

3. After the corn has taken off the hard husk and germ part, the edible taste effect of the corn is improved, and the application scope of the corn is expanded.

4. The peeled corn flour can be directly used to process corn noodles.

5. It is suitable for peeling, breaking, air-selecting, and fine grinding of wheat, rice, corn, sorghum, and other raw grains in small and medium-sized grain and rice processing plants.

6. The finished product processed by the corn peeling and corn grits making machine can directly enter the supermarket and grain and oil wholesale market.

Contact us

If you are seeking a reliable and efficient corn processing solution that guarantees top-quality results, our corn grits making machine is the answer.

Contact us today to inquire about how our machine can cater to your unique processing needs. Let us empower your business with cutting-edge technology and unparalleled efficiency.