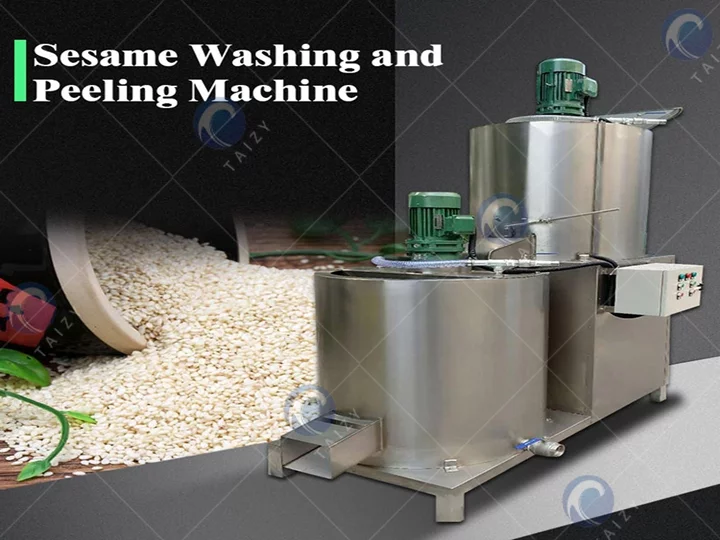

훌륭한 자동 참깨 껍질 벗기기 기계

자동참깨박피탈피기는 참깨의 겉껍질을 깨끗하게 벗겨낼 수 있는 장비입니다. 주요 기능은 껍질을 벗긴 후 껍질과 알맹이를 담그고 껍질을 벗기고 분리하는 것입니다.

참깨가 인간의 단백질 공급원으로 식품으로 사용될 때, 보통 껍질을 벗겨야 합니다. 그리고 껍질을 벗긴 참깨는 더 부드러운 맛이 나며 우리 몸이 더 쉽게 흡수할 수 있습니다. 추가 가공을 위해 우리는 많은 곡식을 껍질을 벗기고, 콩 껍질 벗기기 기계도 보유하고 있어 대두의 껍질을 벗깁니다.

이 기계는 작동이 간단하고 가격이 저렴하며 인력을 절약합니다. 그래서 그것은 사람들에게 없어서는 안될 도우미입니다.

자동 참깨 껍질 벗기기 기계 도입

The automatic sesame seeds peeling hulling machine is a vertical structure that we can fully utilize in the internal space. At the same time, the volume is small, the structure is simple, the operation is convenient, and the maintenance rate is low.

자동 참깨 껍질 벗기기 기계는 복합 교반기를 채택합니다. 이러한 유형의 교반기는 축 전환, 방사형 전환 및 원형 전환을 생성할 수 있습니다. 따라서 사각지대 없이 재료를 완전히 뒤집을 수 있으며 박리율이 높습니다.

복합교반기를 사용하면 참깨를 불리고 껍질을 벗기고 분리하는 시간이 단축됩니다. 따라서 생산 효율성이 향상되고 제품 품질이 향상됩니다.

자동 참깨 껍질 벗기기 기계의 구조

자동 참깨 껍질 벗기기 기계에는 주로 감속기, 탱크, 복합 교반기, 분리기, 히터, 위치 결정 장치 및 다양한 입구 및 출구 파이프가 포함됩니다.

자동 참깨 껍질 벗기기 기계의 작동 과정

먼저 기계를 켜고 걸러낸 참깨를 필링 기계의 첫 번째 통에 붓습니다. 그리고 필링 시간은 3~5분 정도 입니다.

껍질 벗긴 참깨를 두 번째 분리통에 넣기 전에, 망이 막히지 않도록 분리기 안에 물의 3분의 1을 넣으세요.

분리 시에는 3분의 1의 비율(물3참깨1)을 사용하여 알맹이와 껍질을 분리함과 동시에 하단 밸브를 열어 참깨껍질을 물기를 빼주세요. 유입되는 물의 양은 배출되는 물의 양과 같습니다.

5~10분 정도 분리 시간을 준 후, 참깨를 물기를 빼고 깨끗이 씻어주세요.

참깨 껍질 벗기기 기계의 작동 원리

개요:

자동 참깨 껍질 벗기기 및 껍질 제거 기계는 기어 축 교반기를 통해 회전하고 교반하여, 통에 담긴 참깨가 빠르게 위아래로 돌 수 있도록 합니다. 그리고 참깨 사이의 마찰력은 교반기의 회전력과 맞물려 참깨 껍질을 알맹이에서 분리합니다.

일정 시간 작동시킨 후 참깨를 껍질을 벗겨 목표물에 도달시킨 후 게이트 배플을 열어 혼합기의 회전에 따라 참깨 껍질 혼합물을 기계 밖으로 배출시킨다.

담그는 과정의 원리:

참깨를 소량의 가성소다와 함께 뜨거운 물에 넣어주세요. 그런 다음 참깨를 몇 분 동안 담가두세요.

그런 다음 장비를 시작하면 감속기가 교반기를 회전시켜 복합 교반기의 구조적 특성으로 인해 재료가 위아래로 순환되고 참깨와 침지액이 균일하고 완전히 혼합됩니다.

검은 참깨 껍질 벗기기 과정의 작동 원리:

교반기와 참깨 사이, 참깨와 참깨 사이의 상대적인 마찰은 참깨 껍질을 벗기는 목적을 달성하기 위해 참깨의 껍질과 알맹이를 분리합니다.

참깨 껍질을 벗기는 기계의 매개 변수

| 힘 | 헐링 모터 2.2kw, 분리 모터 1.5kw |

| 용량 | 400-500kg/h, 30-50kg/배럴 |

| 헐링 속도 | 80%-85% |

| 무게 | 250kg |

| 크기 | 1400*700*2000mm |

| 재료 | 스테인레스 스틸로 만든 |

자동 참깨 껍질 벗기기 기계의 장점:

1. 껍질을 잘 벗겨줍니다. 처리된 참깨에는 다른 불순물이 없습니다.

2. 가공된 참깨는 흰색이고 밝으며 품질이 좋습니다.

3. 껍질이 없어도 맛이 좋다.

2. 고품질. 탄자니아, 나이지리아, 카타르, 가나, 예멘 등의 많은 고객이 우리 기계의 품질에 만족하고 있습니다.