순환 곡물 건조기 | 쌀과 옥수수용 기계식 건조기

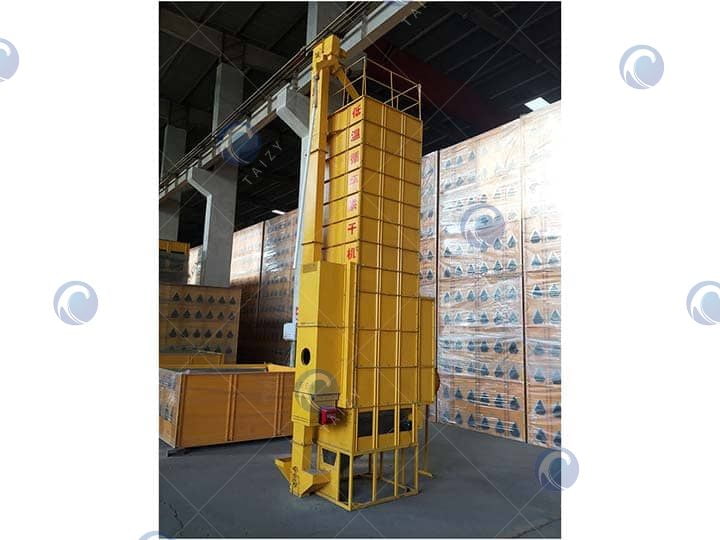

순환식 곡물 건조기는 저온 순환 건조기라고도 불리며 다양한 곡물 종자를 대량으로 건조할 수 있습니다. 일반적으로 이 기계는 대규모 곡물 스테이션, 농장 등에 적합합니다. 처리된 곡물은 장기간 보관하기 쉽고 장거리 운송 및 추가 가공이 용이합니다.

현재 시장에는 내부 구조와 기계 처리 방법이 다른 다양한 형태의 곡물 건조기가 있습니다. 이 기계는 지속적인 개발을 거쳐 왔으며 최신 모델은 4세대 혼합 흐름 곡물 건조기입니다. 당사의 기존 생산 곡물 건조기는 이러한 유형의 최신 기계입니다.

순환 곡물 건조기 소개

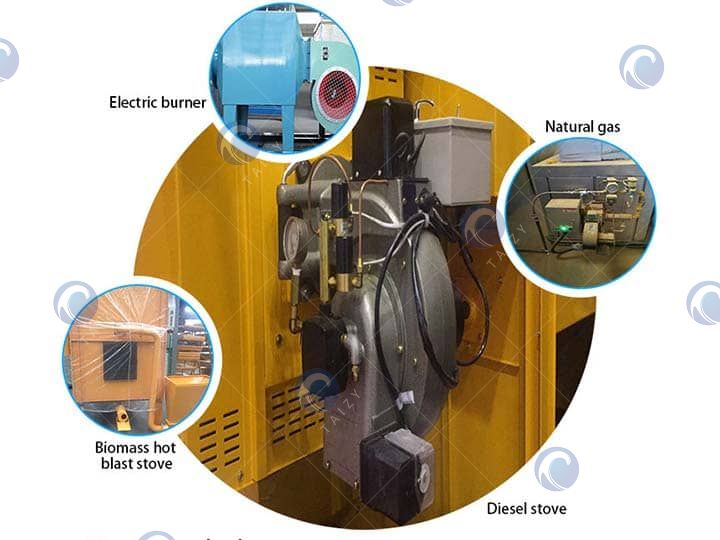

당사의 곡물 건조기는 배치당 출력이 다른 다양한 모델로 제공됩니다. 일반적으로 5H-15 및 5H-32 모델이 더 일반적으로 사용됩니다. 이 곡물 건조기는 최신 건조 형태인 코너 건조층을 갖추고 있습니다. 그리고 이러한 건조 구조는 곡물의 하강 과정을 연장시킬 수 있으므로 뜨거운 공기로 인해 재료가 더욱 완벽하게 건조될 수 있습니다. 또한 이 기계에는 바이오매스 연료, 디젤 스토브, 천연가스 버너, 전기 버너 등 다양한 가열 방식이 있습니다.

처리된 곡물은 곰팡이, 벌레 및 이상 향이 없습니다. 따라서 곡물을 대량으로 건조할 때 건조기는 좋은 조력자입니다. 또한 대량 건조 전에 탈곡기를 사용하여 곡물을 탈곡할 수 있습니다. 저희는 다기능 탈곡기, 쌀-밀 탈곡기, 옥수수 탈곡기 등도 보유하고 있습니다.

쌀 기계식 건조기의 적용 범위는 무엇입니까?

적합한 곡물: 쌀, 밀, 옥수수, 콩, 수수, 기장, 유채, 해바라기 씨 등

적용 분야: 농장, 곡물 스테이션, 곡물을 재배하는 전문 가구.

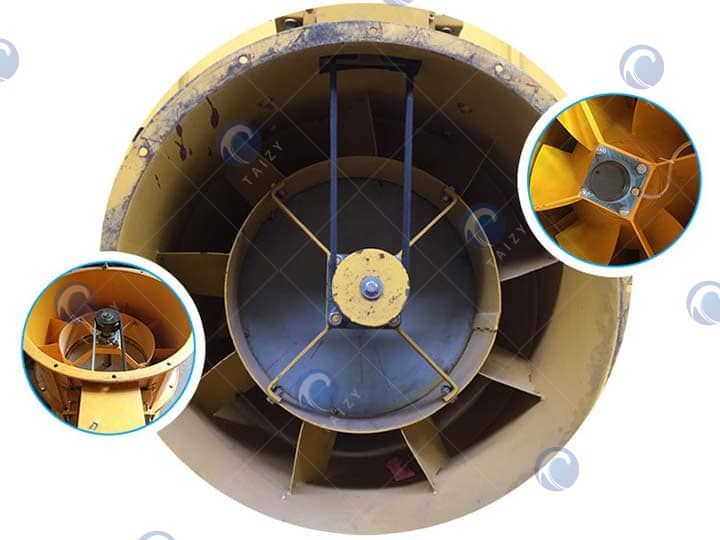

순환곡물건조기의 구조

순환식 곡물 건조기에는 엘리베이터, 사일로, 가열층, 열원 부품, 팬 등이 포함됩니다.

곡물 건조기의 각 부분의 기능은 무엇입니까?

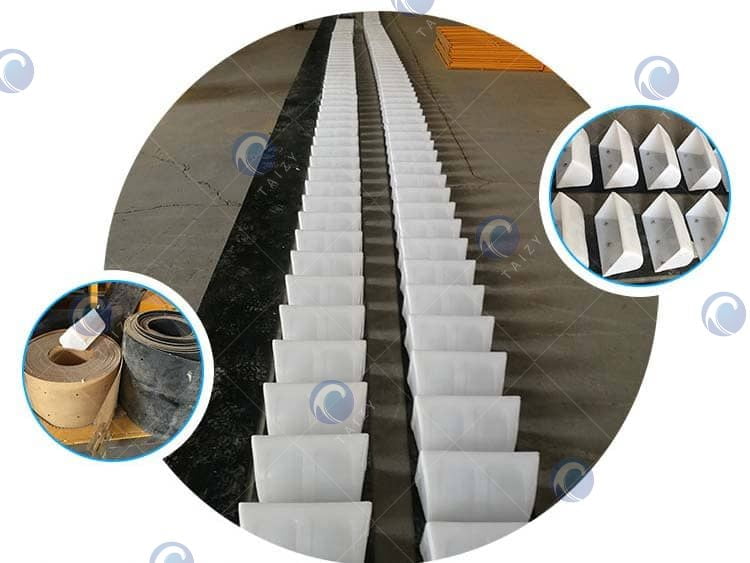

1. 엘리베이터: 곡물을 순환식 곡물 건조기의 사일로로 전달합니다.

2. 사일로: 사일로의 높이는 모델마다 다릅니다. 모델이 클수록 빈 높이가 높아집니다.

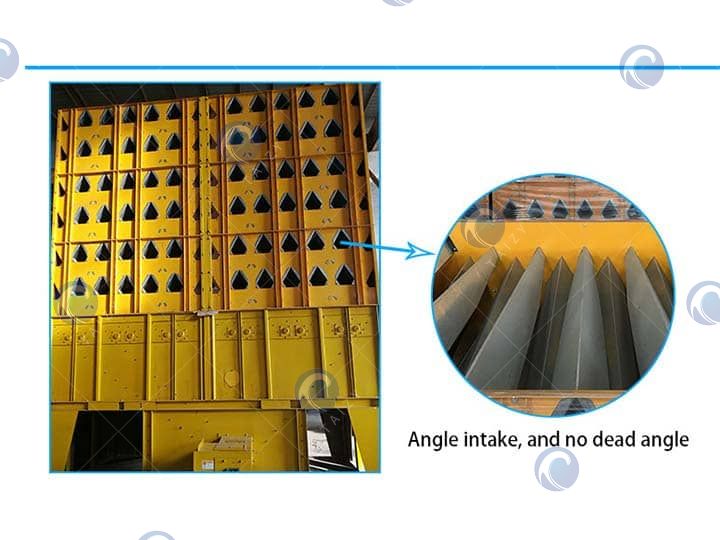

3. 가열 레이어: 이 부분 내부에는 코너 박스 레이어가 있습니다. 뜨거운 공기가 건조층으로 들어가 이 층을 통과하는 곡물을 건조시킵니다. 코너 박스 레이어의 디자인은 재료 낙하 과정을 연장할 수 있으므로 재료를 완전히 건조시킬 수 있습니다. 그리고 먼지가 막히지 않고 뜨거운 공기가 가열층을 원활하게 통과할 수 있습니다.

4. 열원 부분: 순환 곡물 건조기의 이 부분은 바이오매스 열풍 스토브, 디젤 스토브, 천연 가스 버너 및 전기 버너일 수 있습니다. 이러한 모든 발열원에서 생산되는 뜨거운 공기는 깨끗하고 위생적입니다.

5. 팬: 건조층에서 뜨거운 공기를 추출합니다. 고품질 팬은 내구성이 뛰어나고 수명이 깁니다.

그레인 타워 건조기의 작동 과정

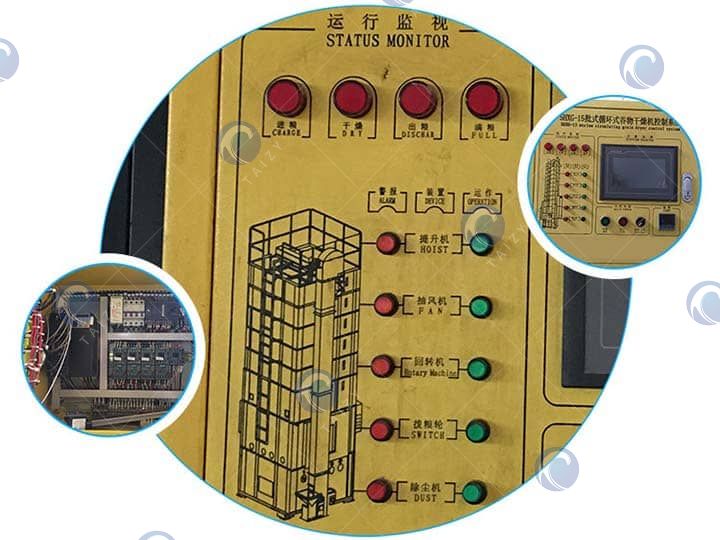

순환식 곡물 건조기는 전체적으로 많은 복잡한 구조를 포함합니다. 주로 전력 시스템, 전송 시스템, 제어 시스템 및 건조 시스템을 포함합니다.

1. 먼저 곡물 저장고에 많은 양의 곡물을 넣습니다.

2. 그런 다음 순환 곡물 건조기를 켜면 기계의 엘리베이터가 곡물을 퍼 올려 건조기의 사일로로 옮깁니다.

3. 곡물이 건조층에 도달할 때까지 계속해서 떨어집니다.

4. 건조층의 모서리 구조에 의해 곡물이 막혀 낙하 속도가 감소합니다. 동시에 뜨거운 공기는 이 층을 통해 곡물을 건조시킵니다.

5. 최종 건조된 곡물이 배출구에서 배출됩니다.

상업용 곡물 건조기의 장점은 무엇입니까?

1. 건조가 균일하고 강수량이 빠르며 시간당 강수량은 약 1.2%로 건조 시간을 효과적으로 단축하고 건조 비용을 절감합니다.

2. 건조 균일한 곡물은 허리 파열율이 낮아 직교류 건조기에 비해 두 배나 낮습니다.

3. 본 기계로 건조된 종자의 발아율은 높으며, 확인된 발아율은 86%입니다.

4. 코너 박스형 공기 흡입구는 매끄러워서 수년간 사용해도 깨끗할 필요가 없습니다.

5. 말린 쌀은 품질이 좋고 시장 판매가 넓으며 상당한 이익을 얻습니다.

6. 조작이 쉽습니다. 작동하기 쉬운 터치 스크린 디스플레이를 갖춘 완전 자동 제어 시스템은 자동으로 물을 결정하고 설정 값에 도달하면 자동으로 멈출 수 있습니다.

7. 환경 친화적인 청소. 환경친화적인 열풍난로를 장착하여 식품이 오염되지 않도록 하며, 동종 제품과 동일하게 시대를 초월한 소음, 약한 진동, 연료 절약, 저렴한 비용, 긴 수명을 보장합니다.

배치 곡물 건조기

FAQ

1. 1.15형의 시간당 수분제거율은 어떻게 되나요?

1-1.2%.

2. 5H-15형과 5H-32형 건조층의 차이점은 무엇인가요?

높이는 같고 폭은 다르며, 5H-32형은 더 넓고 길어서 5H-15형보다 2배 길고, 5H-15는 공기 흡입구가 1개, 5H-32는 공기 흡입구가 2개입니다.

3. 건조기에 곡물이 가득 차 있는지 어떻게 알 수 있나요?

제어 캐비닛에 경고등이 있습니다.

4. 순환곡물 건조기의 내부 온도는 얼마입니까?

지역마다 온도가 다르며 상업용 곡물은 일반적으로 섭씨 60도 정도, 씨앗은 섭씨 40도 정도입니다.

5. 버킷 엘리베이터의 재질은 무엇입니까?

순수 나일론 캔버스.

6. 제어 캐비닛의 브랜드와 기능은 무엇입니까?

독일 지멘스, PLC 자동화 컨트롤 박스.