Máquina de prensa de óleo de parafuso | Prensa de óleo hidráulico para amendoim

| Modelo | 6YL-80 |

| Potência principal (kW) | 4 |

| Capacidade (kg/h) | 80-120 |

| Peso (kg) | 880 |

| Tamanho (mm) | 1700*110*1600 |

Oferecemos quatro tipos de prensas de óleo de parafuso para atender às diversas necessidades dos usuários: semiautomáticas, totalmente automáticas, prensas a frio e a quente e prensas hidráulicas. Com capacidade de processamento que varia de 40 a 350 kg/h, essas máquinas são projetadas para oferecer desempenho e eficiência excepcionais.

Nossas prensas de óleo não se limitam a materiais tradicionais como amendoim; eles também podem extrair com eficiência óleo de gergelim, soja, colza e muitas outras sementes oleaginosas. Apresentando alta eficiência, economia de energia, operação fácil e excelente capacidade de produção, essas máquinas são a escolha ideal para a indústria de processamento de oleaginosas.

Quais materiais são adequados para máquinas de extração de óleo?

- Sementes de girassol. As sementes de girassol contêm uma quantidade significativa de óleo e são comumente usadas para extração de óleo. O óleo de girassol é conhecido por seu sabor leve e alto ponto de fumaça, tornando-o adequado para fritar e cozinhar.

- Colza (Canola). As sementes de colza, também conhecidas como sementes de canola, são amplamente utilizadas para extração de óleo. O óleo de canola tem baixo teor de gordura saturada e sabor neutro, o que o torna adequado para diversas aplicações culinárias.

- Amendoim (amendoim). O amendoim é rico em óleo e comumente usado para extração de óleo. O óleo de amendoim tem um sabor distinto e é frequentemente usado na culinária asiática.

- Sementes de gergelim. As sementes de gergelim são conhecidas por seu alto teor de óleo e são comumente usadas para extração de óleo. O óleo de gergelim é valorizado por seu sabor de nozes e é usado em diversas cozinhas em todo o mundo.

Tipo 1: Prensa de óleo hidráulico

Princípio de funcionamento:

A prensa de óleo hidráulico usa líquido como meio para transmissão de pressão, gerando pressão de trabalho para espremer o óleo no anel do bolo.

Opções de modelo:

- Oferecemos quatro modelos para atender às diversas necessidades de capacidade.

- Modelos populares: 6YZ-180, 6YZ-230 e 6YZ-260.

- Alimentado por um motor para operação eficiente.

Qualidade de óleo melhorada:

Um separador é usado durante a colocação do material para garantir uma compressão completa.

Resultados em:

- Menos impurezas no óleo final.

- Qualidade superior do óleo.

- Alto valor do bolo para uso secundário.

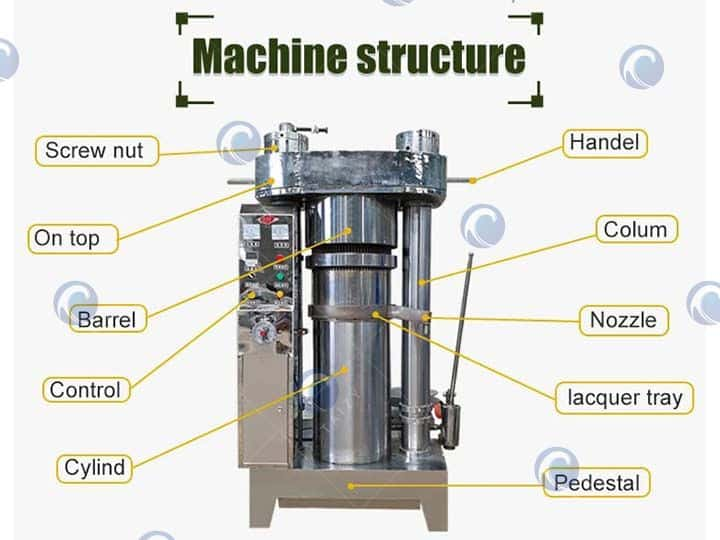

Estrutura da prensa de óleo de gergelim

Componentes chave: placa superior, caixa de distribuição, manómetro, base, anel de reforço, barril de material, placa coletora de óleo, cilindro de óleo, êmbolo.

Características:

- estrutura compacta

- design atraente e moderno

- economia de espaço com uma pegada pequena

- otimizado para extração eficaz de óleo de gergelim

Fluxo de trabalho da prensa de óleo hidráulico automático

- Pré-aquecimento:

- Antes de cada extração de óleo, pré-aqueça a máquina.

- Verão e outono: 70-80°C

- Inverno e primavera: 80-100°C

- Antes de cada extração de óleo, pré-aqueça a máquina.

- Preparação da máquina:

- Opere a máquina 1 a 2 vezes antes da extração do óleo por 5 a 10 minutos com ar para diluir o óleo hidráulico, garantindo uma operação suave.

- Processo de extração de óleo:

- Coloque as oleaginosas fritas na câmara de prensagem.

- Quando o nível do óleo estiver ligeiramente abaixo da face superior, adicione o separador.

- Durante o processo de reforço, certifique-se de que a máquina seja monitorada o tempo todo.

- Quando nenhum óleo vazar da junta de óleo da câmara de prensagem, a extração estará completa.

- Conclusão:

- Desligue a máquina e remova o bolo de óleo.

Informações detalhadas sobre prensa de óleo hidráulico

| Modelo | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| Tamanho (mm) | 920*480*1190 | 1065*540*1550 | 900*1000*1560 | 980*1050*1680 |

| Peso (kg) | 450 | 880 | 1250 | 1680 |

| Pressão em kg (kn) | 1600 | 2200 | 2600 | 3000 |

| Pressão máxima de trabalho | 55Mpa | 55Mpa | 55Mpa | 55Mpa |

| Potência de aquecimento elétrico (kw) | 1 | 1 | 1.2 | 2 |

| Peso de sementes de gergelim (kg) | 2-4 | 5-8 | 6-10 | 7-18 |

| Potência (kw) | 3(220v) | 1.5 | 1.5 | 2.2 |

Quais são as máquinas que podem trabalhar com a prensa de óleo hidráulico doméstico?

Há uma máquina de peneiramento de gergelim, máquina de torrefação de gergelim, máquina centrífuga de filtragem de óleo, máquina para quebrar nozes de amêndoa e pêssego, um elevador, etc.

Estas máquinas podem formar uma linha de produção completa. Você pode conseguir um trabalho mais eficiente e conveniente. Assim, você pode escolher a máquina certa de acordo com suas necessidades.

As características marcantes do expulsor de óleo hidráulico profissional

- Alta eficiência, ecologicamente correta, economia de energia e entrega produtos de alto valor.

- Opera silenciosamente com um método de prensagem física que não requer aquecimento ou aditivos químicos.

- Design fácil de usar com componentes duráveis, garantindo fácil operação e longa vida útil.

- A prensa de óleo hidráulico destaca-se pela sua pressão excepcionalmente alta, permitindo uma ótima extração de óleo.

Tipo 2: prensa automática de óleo de parafuso

Modelos de máquina:

- Disponível em cinco modelos com base no diâmetro do parafuso: 6YL-60, 6YL-70, 6YL-80, 6YL-100, 6YL-125.

Características de prensagem a quente:

- O óleo prensado a quente é mais perfumado e com uma cor mais rica.

- Os materiais são pré-aquecidos antes da prensagem.

Fonte de energia:

- Operado por um motor para desempenho consistente.

Prensagem ajustável:

- O material residual é descarregado na extremidade do parafuso.

- O grau de extrusão do material pode ser ajustado usando a alça na frente da tremonha.

Sistema de filtragem de óleo:

- Equipado com barril de filtro de óleo.

- Utiliza uma camada de papel de filtro de óleo para remover impurezas.

- Emprega filtragem de óleo a vácuo para criar pressão negativa, permitindo que o ar externo pressione o óleo para dentro do barril.

Vantagem de desempenho:

- Oferece uma taxa de extração de óleo mais alta em comparação aos modelos semiautomáticos.

Parâmetro da máquina automática de prensa de óleo de parafuso

| Modelo | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| Diâmetro do parafuso (mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| Velocidade de rotação do parafuso (r/min) | 64 | 38 | 35 | 37 | 34 |

| Potência principal (kW) | 2.2 | 3 | 4 | 7.5 | 15 |

| Potência da bomba de vácuo (kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| Potência de aquecimento (kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| Capacidade (kg/h) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| Peso (kg) | 220 | 280 | 880 | 1100 | 1400 |

| Tamanho (mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

Tipo 3: Prensa de óleo de parafuso para amendoim

Mecanismo de prensagem de óleo:

- Semelhante ao Tipo 2, a parte de prensagem é projetada para extração eficiente de óleo de amendoim.

Característica adicional:

- Equipado com rosca alimentadora que permite a circulação do material.

Vantagens da prensagem a frio:

- Os nutrientes do óleo são preservados sem serem destruídos.

- O bolo pode ser prensado várias vezes devido ao menor rendimento de óleo.

Características do óleo:

- O óleo prensado a quente tem uma cor mais escura.

- O óleo prensado a frio tem uma cor mais clara.

Fonte de energia:

- Operado por um motor para desempenho confiável.

Qual é a especificação da prensa de óleo?

| Modelo | ZY-125 | ZY-150 |

| Motor | 15 kW | 37 kW |

| Motor da bomba de vácuo | 1,5 kW | 2,2 kW |

| Capacidade | 150-200 kg/hora | 300-350 kg/hora |

| Peso | 986kg | 2500kg |

| Tamanho | 1900*1100*1500mm | 2100*1300*1700mm |

Tipo 4: Prensa de óleo de parafuso semiautomática

A prensa de óleo de parafuso semiautomática não possui outros acessórios. Só tem a parte que pode extrair óleo. A estrutura e operação da máquina também são mais simples.

A potência desta prensa de óleo semiautomática pode ser um motor elétrico e um motor diesel. Os clientes podem escolher a potência de acordo com suas necessidades. Assim, as máquinas deste modelo também são mais acessíveis.

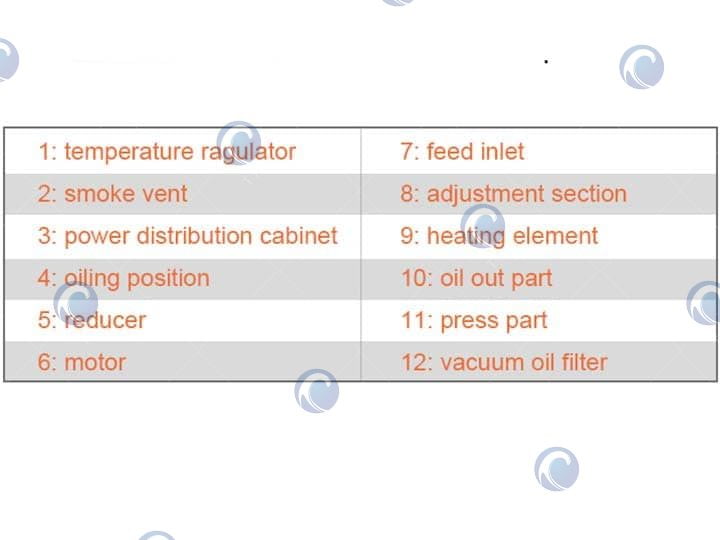

Qual é a estrutura da prensa de óleo de parafuso único?

A estrutura central do Tipo 2 e Tipo 4 é semelhante, incluindo entrada de material, seção de ajuste, elemento de aquecimento, peça de prensa, peça de saída de óleo, potência (motor, motor diesel), etc.

Dois conjuntos de expulsores de petróleo vendidos a Angola

Na semana passada tivemos um cliente de Angola. Ele quer iniciar um projeto de prensagem de óleo. E através do Alibaba, ele obteve as nossas informações de contacto e enviou-nos um inquérito.

Este cliente deseja prensar óleo de soja. Além disso, de acordo com sua necessidade de produção, recomendamos a ele o modelo ZY-150. Finalmente, ele comprou dois conjuntos de prensas de óleo.

Contate-nos agora!

Concluindo, a prensa de óleo de parafuso oferece uma solução altamente eficiente e confiável para extrair óleo premium de uma variedade de sementes oleaginosas, incluindo amendoim.

Para uma operação mais eficiente, pode ser emparelhada sem problemas com uma máquina descascadora de amendoins para uma descascagem eficiente e uma máquina de colheita de amendoim para recolher matérias-primas. Em conjunto, estas máquinas fornecem um sistema completo e optimizado para o seu processo de produção de óleo.

Para mais informações ou para obter um orçamento, não hesite em contactar-nos hoje!