Combinar máquina colhedora de arroz e trigo

| Nome | Colheitadeira de arroz de esteira plana |

| Tamanho | 3100*1440*1630mm |

| Peso | 570kg |

| Largura de corte | 1100 mm |

| Volume de alimentação | 1,05kg/s |

A máquina combinada de ceifa e debulha de arroz e trigo pode colher culturas de arroz e trigo de forma eficiente. Corta as plantas de arroz com lâminas afiadas, separa os grãos das cascas com um mecanismo de debulha e utiliza um sistema de transporte para mover o arroz e o trigo colhidos para armazenamento.

Os modelos modernos apresentam automatização avançada para ajustar a altura da lâmina, gerir a debulha e otimizar a eficiência entre diferentes variedades de arroz. A nossa gama inclui dois modelos: o ceifeiro de esteira plana para arroz para campos alagados, e o ceifeiro de esteira triangular para trigo para campos de arroz, ambos com largura de corte de 1100mm.

Estas máquinas aumentam a produtividade, reduzem os custos de mão-de-obra e operam de forma eficaz em diversos terrenos, oferecendo uma solução confiável para a moderna agricultura de arroz.

Diferentes tipos de máquina combinada de ceifa e debulha de arroz e trigo

Primeiro, vamos aprofundar-nos nos dois tipos principais de máquinas ceifeira-debulhadora para arroz e trigo.

Colheitadeira de arroz de esteira plana

Características

- O desenho de esteira plana aumenta a área de contacto com o solo.

- Melhor flutuabilidade e estabilidade para lama profunda e terrenos difíceis.

Vantagens

- A distribuição uniforme do peso reduz a compactação do solo.

- Melhora a estabilidade e a manobrabilidade em condições húmidas e lamacentas.

Cenários aplicáveis

- Perfeito para arrozais de lama profunda, evitando afundamento e assegurando uma operação suave.

| Tamanho (MM) | 3100*1440*1630 | |

| Peso (kg) | 570 | |

| Largura de corte (MM) | 1100 | |

| Terreno mínimo folga (MM) | 190 | |

| Terreno médio pressão (KPA) | 10.9 | |

| Alimentação volume (kg/s) | 1.05 | |

Colheitadeira de arroz sobre esteiras triangulares

Características

- Desenho de esteira triangular para campos secos e arrozais de lama superficial.

- Maior manobrabilidade e adaptabilidade a vários terrenos.

Vantagens

- Excelente desempenho em lama superficial ou condições secas.

- Navega facilmente por diferentes ambientes agrícolas.

Cenários aplicáveis

Assegura desempenho flexível e eficiente em lama superficial ou áreas secas.

Adequado para arrozais e campos secos.

| Tamanho (MM) | 3100*1440*1630 | |

| Peso (kg) | 570 | |

| Largura de corte (MM) | 1100 | |

| Terreno mínimo folga (MM) | 190 | |

| Terreno médio pressão (KPA) | 10.9 | |

| Alimentação volume (kg/s) | 1.05 | |

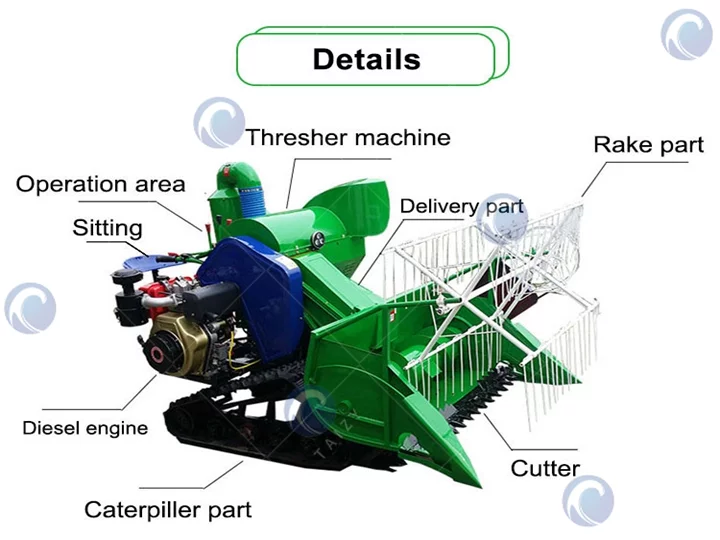

Estrutura da máquina combinada de ceifa e debulha de arroz e trigo

Esta ceifeira combinada de arroz integra corte, recolha, debulha e manuseio de grãos numa única máquina compacta, tornando-a altamente eficiente tanto para agricultura em pequena como em grande escala. A sua estrutura foi desenhada para funcionar suavemente mesmo em arrozais lamacentos ou terrenos irregulares, graças ao motor potente e às lagartas estáveis.

Componentes principais:

- Parte de rastelo – Coleta e guia as plantas de arroz em direção ao cortador.

- Cortador – Corta as plantas de arroz maduras de forma eficiente.

- Parte de entrega – Transfere as plantas cortadas para o sistema de debulha.

- Máquina de debulhar – Separa os grãos de arroz dos talos e cascas.

- Motor diesel – Fornece potência forte e confiável para todas as operações.

- Parte de lagarta – Garante movimento estável e tração em terrenos lamacentos ou acidentados.

- Área de operação e assento – Permite que o operador controle e monitore a máquina confortavelmente.

Este desenho tudo-em-um reduz o trabalho manual, encurta o tempo de colheita e melhora o rendimento dos grãos, tornando-a uma escolha ideal para a agricultura moderna do arroz.

Como funciona a máquina combinada de ceifa e debulha de arroz e trigo?

Tendo entendido os tipos de máquinas, vamos mergulhar no processo de trabalho da colheitadeira de arroz.

O processo de trabalho de uma colheitadeira de arroz envolve várias etapas para colher e processar com eficiência as culturas de arroz. Aqui está uma visão geral do processo de trabalho típico.

- Indo para o campo – Leva a colhedora de arroz para o campo, posiciona e ajusta de acordo com o tipo e altura da cultura.

- Corte e coleta – Aciona o cortador para colher plantas de arroz maduras (panículas) e alimentá-las na máquina.

- Debulha – Separa os grãos de arroz do restante da planta usando o mecanismo de debulha.

- Separação – Remove palha e cascas, deixando apenas grãos de arroz limpos.

- Limpeza – Elimina poeira, palha e outras impurezas.

- Transporte – Move os grãos de arroz limpos para o compartimento ou recipiente de armazenamento do colhedor.

Vantagens principais da máquina combinada de ceifa e debulha de arroz e trigo

Agora que revimos o processo de funcionamento, vamos resumir as principais vantagens da máquina ceifeira-debulhadora para arroz e trigo.

- Colheita integrada – Combina corte, debulha e manuseio de grãos em um único processo, reduzindo tempo e trabalho.

- Projetos especializados – Modelos de esteira plana e triangular garantem tração e estabilidade tanto em campos de arroz quanto em terrenos secos.

- Eficiência de debulha – Mecanismos avançados minimizam a perda de grãos e mantêm uma produção de alta qualidade.

- Adaptabilidade – As trilhas de lagarta lidam com terrenos lamacentos ou irregulares enquanto reduzem a compactação do solo.

- Maior produtividade – Economiza tempo, reduz custos e aumenta a produção para ciclos de cultivo mais eficientes e maior rentabilidade.

Caso de sucesso da máquina combinada de ceifa e debulha de arroz e trigo

Fornecemos o mais recente modelo de colheitadeira e debulhadora de trigo para uma grande fazenda no Centro-Oeste dos Estados Unidos, aumentando significativamente sua eficiência na colheita e debulha de trigo. Este equipamento movimenta com eficiência grandes campos de trigo e separa com precisão os grãos da palha, reduzindo substancialmente o desperdício e as perdas.

A equipe de gestão da fazenda forneceu feedback positivo, observando como a máquina simplificou operações complexas, economizou trabalho e tempo e melhorou a qualidade dos grãos de trigo. Além disso, permitiu às explorações agrícolas comercializar os seus produtos a preços mais elevados, aumentando a sua competitividade e o retorno económico.

Contate-nos!

When you choose our arroz harvester and thresher machine, you’re not just opting for efficient harvesting and threshing solutions—you’re laying a solid foundation for future agricultural productivity.

Além disso, complemente as suas operações com a nossa Máquina debulhadora de arroz e trigo e a Máquina debulhadora de cereais, garantindo apoio abrangente para todas as suas necessidades de processamento de culturas. Escolha-nos pela profissionalidade e fiabilidade em que pode confiar.