เครื่องตัดฟาง丨อุปกรณ์เครื่องตัดแกลบ

เครื่องตัดฟางมีจุดประสงค์ในการตัดและบดวัสดุต่างๆ เช่น แกลบ ฟาง ก้านข้าวโพด ข้าวฟ่าง หญ้าหมัก และฟางแทบทุกชนิดให้เป็นหญ้าที่ผ่านการแปรรูปอย่างประณีต ซึ่งเหมาะสำหรับการให้อาหารสัตว์

หญ้าที่ผ่านการแปรรูปอย่างประณีตนี้สามารถใช้เป็นอาหารสัตว์ได้หลากหลาย เช่น วัว วัว ม้า แพะ แกะ ไก่ เป็ด กระต่าย ฯลฯ ช่วยให้สัตว์ย่อยง่าย

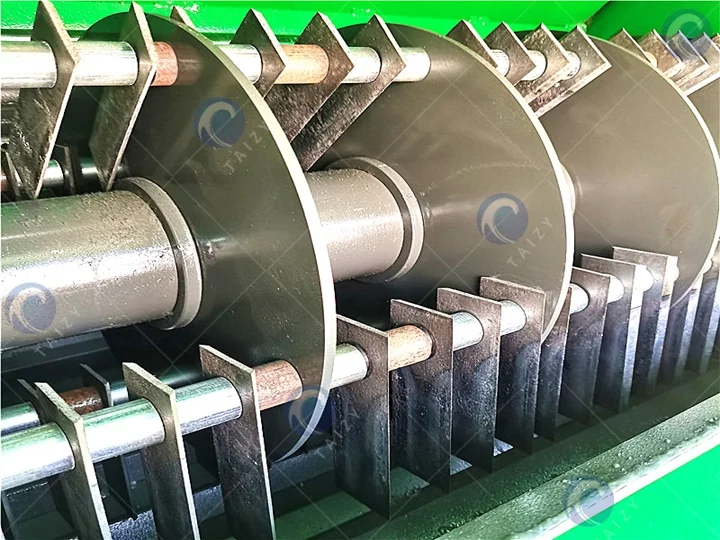

ตัวเครื่องสร้างด้วยโครงสร้างใบมีดค้อนที่แข็งแกร่งและทนทาน นอกจากนี้ ยังรวมเอาสายพานลำเลียงเพื่อการป้อนหญ้าอย่างมีประสิทธิภาพ ทำให้มั่นใจได้ถึงประสิทธิภาพการทำงานขั้นต่ำอย่างน้อย 4 ตันต่อชั่วโมง

พารามิเตอร์ของเครื่องตัดฟาง

| แบบอย่าง | อาร์เอสเจ-6 | RSJ-10 | RSJ-15 |

| พลัง | 15+1.5kw | 22+2.2กิโลวัตต์ | 30+4kw |

| ความเร็วของเพลาหลัก | 1750r/นาที | 1750r/นาที | 1750r/นาที |

| ความจุ | 4-7 ตัน/ชม | 7-10 ตัน/ชม | 15 ตัน/ชม |

| ปริมาณใบมีด | 40 ชิ้น | 48 ชิ้น | 80 ชิ้น |

| ขนาด (ยาว * กว้าง * สูง) | 2750*950*1500มม | 3130*890*1230มม | 3900*1400*1200มม |

วัสดุที่เหมาะสมสำหรับเครื่องตัดหญ้าหมัก

เครื่องตัดหญ้าหมักเป็นอุปกรณ์อเนกประสงค์ที่เหมาะสำหรับการแปรรูปวัสดุต่างๆ วัสดุหลักที่ใช้ได้แก่ หญ้าและฟาง ซึ่งครอบคลุมแหล่งที่มาจากพืชหลากหลายชนิด

ซึ่งรวมถึงแต่ไม่จำกัดเพียงหญ้าประเภทต่างๆ เช่น หญ้าสีเขียวและหญ้าแห้ง ตลอดจนฟางประเภทต่างๆ เช่น ก้านข้าวโพด ก้านข้าวฟ่าง และอื่นๆ

อุปกรณ์เครื่องตัดแกลบทำงานอย่างไร?

1. วัสดุให้อาหาร:

วัตถุดิบซึ่งอาจเป็นฟาง หญ้าแห้ง หรืออาหารสัตว์ประเภทอื่นๆ จะถูกป้อนด้วยมือหรือโดยเครื่องจักรเข้าไปในเครื่องตัดแกลบ เครื่องตัดฟางมีสายพานลำเลียงเพื่อช่วยในกระบวนการนี้

2. กลไกการตัด:

ภายในเครื่องตัดแกลบมีกลไกการตัดที่ประกอบด้วยใบมีดหมุนหรือมีด ใบมีดเหล่านี้ออกแบบมาเพื่อตัดวัตถุดิบให้เป็นชิ้นเล็กลงและจัดการได้ง่ายขึ้น

3. แหล่งพลังงาน:

เครื่องตัดแกลบใช้พลังงานจากแหล่งต่างๆ รวมถึงไฟฟ้าและเครื่องยนต์ดีเซล แหล่งพลังงานขับเคลื่อนกลไกการตัดเพื่อทำการตัด

4. การรวบรวมหรือการจำหน่าย:

วัสดุที่ตัดแล้วจะถูกระบายออกทางพวยกา วิธีการรวบรวมขึ้นอยู่กับวัตถุประสงค์การใช้งาน

5. คุณสมบัติด้านความปลอดภัย:

เครื่องตัดแกลบสมัยใหม่มีคุณสมบัติด้านความปลอดภัย เช่น ปุ่มหยุดฉุกเฉิน ตัวป้องกันรอบๆ ชิ้นส่วนที่เคลื่อนไหว และการป้องกันการโอเวอร์โหลดเพื่อความปลอดภัยของผู้ปฏิบัติงาน

ข้อดีที่สำคัญของเครื่องตัดฟาง

- ความเก่งกาจ: เครื่องนี้ออกแบบมาเพื่อตัดและบดวัสดุต่างๆ รวมถึงแกลบ ฟาง ก้านข้าวโพด ข้าวฟ่าง และหญ้าหมัก ความคล่องตัวนี้ทำให้เหมาะสำหรับการแปรรูปสารตกค้างทางการเกษตรหลากหลายประเภท

- โครงสร้างใบมีดค้อนที่ทนทาน: การใช้โครงสร้างใบค้อนช่วยเพิ่มความทนทานและความแข็งแรง การออกแบบนี้ช่วยให้มั่นใจได้ว่าเครื่องจักรสามารถทนทานต่อการใช้งานอย่างต่อเนื่องในการเกษตรได้

- สายพานลำเลียงเพื่อการป้อนที่มีประสิทธิภาพ: การรวมสายพานลำเลียงช่วยให้กระบวนการป้อนอาหารสะดวกขึ้น ซึ่งส่งผลให้ประสิทธิภาพในการทำงานสูงขึ้น คุณสมบัตินี้ช่วยให้มั่นใจได้ถึงการไหลของวัสดุผ่านเครื่องจักรที่สม่ำเสมอและคล่องตัว

- ประสิทธิภาพการทำงานสูง: เครื่องจักรสามารถบรรลุประสิทธิภาพการทำงานอย่างน้อย 4 ตันต่อชั่วโมง ประสิทธิภาพสูงนี้มีความสำคัญอย่างยิ่งต่อการดำเนินการทางการเกษตรขนาดใหญ่ ซึ่งช่วยประหยัดเวลาและแรงงาน

ความแตกต่างระหว่างเครื่องตัดฟางและเครื่องตัดหญ้า

ความแตกต่างระหว่างเครื่องตัดฟางและเครื่องตัดหญ้าอยู่ที่การออกแบบและลักษณะของวัสดุที่ผ่านกระบวนการ ความแตกต่างหลักประการหนึ่งคือจำนวนใบมีดที่ใช้ในแต่ละเครื่อง เครื่องตัดฟางมีใบมีดหลายใบ จึงมีกลไกการตัดที่ซับซ้อนมากขึ้น ในทางตรงกันข้าม เครื่องตัดหญ้าใช้ใบมีดเพียงใบเดียว ซึ่งทำให้โครงสร้างการตัดง่ายขึ้น

ความแตกต่างที่น่าสังเกตอีกประการหนึ่งคือรูปแบบของผลิตภัณฑ์ขั้นสุดท้ายที่ผลิตโดยแต่ละเครื่อง เครื่องตัดฟางจะได้ชิ้นงานที่มีลักษณะคล้ายเกลียวยาวเป็นผลลัพธ์สุดท้าย เส้นละเอียดเหล่านี้เหมาะอย่างยิ่งสำหรับการใช้งาน เช่น การให้อาหารโค วัว ม้า และปศุสัตว์อื่นๆ เนื่องจากย่อยง่าย

ในทางกลับกัน เครื่องตัดหญ้าจะสร้างผลิตภัณฑ์ขั้นสุดท้ายที่มีรูปร่างเป็นบล็อก การออกแบบนี้มีข้อได้เปรียบโดยเฉพาะอย่างยิ่งสำหรับการใช้งานบางประเภทที่ต้องการชิ้นหญ้าที่หนากว่า เพื่อรองรับความต้องการในการให้อาหารของสัตว์ต่างๆ

อุปกรณ์สนับสนุนเครื่องตัดฟาง

เครื่องตัดฟางของเราไม่เพียงแต่ให้ฟังก์ชันการตัดขั้นสูง แต่ยังสามารถจับคู่กับเครื่องอัดฟางซีเลจเพื่อมอบโซลูชันครบวงจรสำหรับการแปรรูปอาหารสัตว์ การรวมเครื่องตัดฟางกับ เครื่องอัดฟางซีเลจ ช่วยให้การถนอมอาหารสัตว์มีประสิทธิภาพมากขึ้น ยืดอายุการเก็บรักษา และสะดวกต่อการขนส่งเมื่อจำเป็น

การรวมเครื่องอัดฟางหญ้าหมักเข้าด้วยกันทำให้ง่ายต่อการบีบอัดวัสดุที่ตัดแล้วลงในบรรจุภัณฑ์ที่ห่อแน่น เพิ่มความหนาแน่นของอาหาร และลดความต้องการพื้นที่จัดเก็บได้อย่างมีประสิทธิภาพ สิ่งนี้ไม่เพียงแต่ช่วยลดต้นทุนการจัดเก็บเท่านั้น แต่ยังช่วยให้มั่นใจว่าอาหารสัตว์ยังคงสดและมีคุณค่าทางโภชนาการเป็นระยะเวลานานอีกด้วย

นอกจากนี้ ระบบเครื่องตัดฟางเมื่อจับคู่กับเครื่องอัดฟางหญ้าหมัก จะช่วยเพิ่มความคล่องตัวให้กับกระบวนการขนส่งอาหารสัตว์ อาหารบรรจุกล่องสามารถจัดการได้มากขึ้นสำหรับการวางซ้อนและขนย้าย เพิ่มความสะดวกในการขนส่ง และทำให้การผลิตทางการเกษตรมีประสิทธิภาพมากขึ้น

ลงทุนในเครื่องตัดฟางของเรา

ในฐานะผู้จำหน่ายชั้นนำของเครื่องตัด ฟาง เรามุ่งมั่นที่จะส่งมอบอุปกรณ์ที่โดดเด่นทั้งด้านประสิทธิภาพและความน่าเชื่อถือเพื่อตอบโจทย์ความต้องการทางการเกษตรของคุณ เป็นที่รู้จักในด้านเทคโนโลยีล้ำหน้า การออกแบบทนทาน และความสามารถในการผลิตที่มีประสิทธิภาพ บริษัทของเรามอบโซลูชันที่เชื่อถือได้เพื่อเพิ่มประสิทธิภาพการแปรรูปอาหารสัตว์

ในขณะเดียวกัน ความพึงพอใจของลูกค้าถือเป็นสิ่งสำคัญสูงสุดของเรามาโดยตลอด ทีมงานมืออาชีพของเราทุ่มเทเพื่อมอบบริการก่อนการขายและหลังการขายคุณภาพสูง เพื่อให้มั่นใจถึงการสนับสนุนที่ครอบคลุมตลอดทั้งการซื้อ การติดตั้ง และการใช้งานของคุณ

เรายินดีต้อนรับคุณอย่างอบอุ่นเพื่อสอบถามและเยี่ยมชมเราเพื่อทำความเข้าใจอย่างลึกซึ้งยิ่งขึ้นเกี่ยวกับเครื่องตัดฟางขั้นสูงของเรา เมื่อเลือกผลิตภัณฑ์ของเรา คุณจะสามารถเข้าถึงประสิทธิภาพสูง ความทนทาน และประสิทธิภาพการดำเนินงานที่ยอดเยี่ยม

โปรดติดต่อเราได้ตลอดเวลา เราหวังเป็นอย่างยิ่งว่าจะได้มอบโซลูชั่นที่ดีที่สุดให้กับคุณและมีส่วนร่วมในความก้าวหน้าของการผลิตทางการเกษตรร่วมกัน