เครื่องโรงสีดิสก์ | เครื่องบดเมล็ดพืช | เครื่องบดเมล็ดพืชด้วยพายุไซโคลน

เครื่องบดดิสก์เป็นอุปกรณ์บดอเนกประสงค์ที่มีประสิทธิภาพสูง ออกแบบมาเพื่อการประมวลผลวัสดุหลากหลายประเภทให้เป็นผงละเอียด ข้อได้เปรียบที่สำคัญ ได้แก่ ประสิทธิภาพการบดสูง การกระจายขนาดอนุภาคสม่ำเสมอ และโครงสร้างที่แข็งแกร่ง

เครื่องบดเมล็ดพืชมีการตั้งค่าการบดที่ปรับได้เพื่อให้ได้ความละเอียดที่ต้องการ ทำให้เหมาะสำหรับการใช้งานต่างๆ เช่น การแปรรูปอาหาร ยา และสารเคมี

ด้วยจานที่ทนทานซึ่งทำจากวัสดุคุณภาพสูง เครื่องบดจานจึงรับประกันประสิทธิภาพที่สม่ำเสมอและการทำงานที่ยาวนาน การออกแบบที่กะทัดรัดและการบำรุงรักษาที่ง่ายดายช่วยเพิ่มความน่าดึงดูดใจให้กับการดำเนินงานทั้งในระดับขนาดเล็กและระดับอุตสาหกรรม

ความรู้เบื้องต้นเกี่ยวกับเครื่องบดเมล็ดพืช

Taizy ของเราผลิตเครื่องบดเมล็ดพืชหลากหลายประเภท มีเครื่องจักรโรงสีดิสก์ เครื่องบดเมล็ดพืช และเครื่องบดเมล็ดพืชแบบไซโคลน เป็นต้น

เครื่องจักรทั้งหมดนี้สามารถบดเมล็ดพืช วัสดุยา อาหาร อาหารสัตว์ ฯลฯ เราสามารถกินวัสดุแปรรูปหรือใช้ในการเลี้ยงสัตว์ปีก เป็นต้น เครื่องบดเมล็ดพืชเหล่านี้มีโครงสร้างเรียบง่าย ติดตั้งง่าย ใช้งานง่าย และประหยัดพลังงาน .

นอกจากนี้ เรายังผลิตเครื่องปอกเมล็ดและเครื่องทำเกริตส์ข้าวโพด เครื่องจักรทั้งหมดนี้จะช่วยให้คุณแปรรูปธัญพืชได้อย่างง่ายดาย.

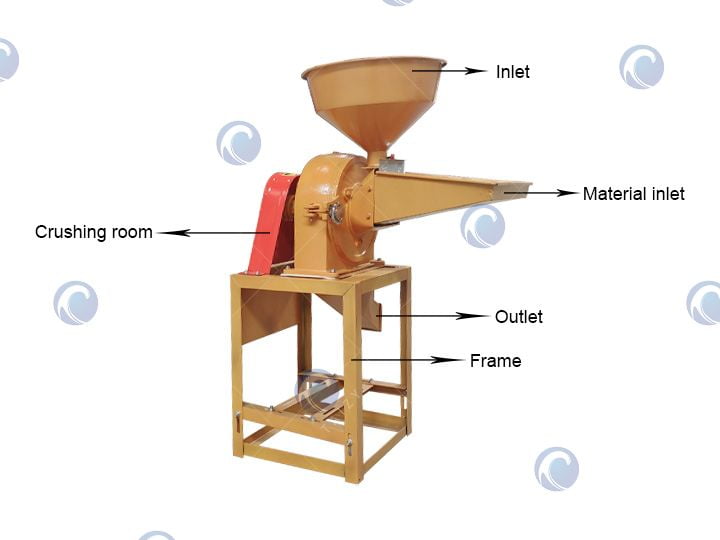

ประเภทที่ 1: เครื่องโรงสีดิสก์

เครื่องบดดิสก์เป็นอุปกรณ์พิเศษที่สามารถบดเมล็ดธัญพืช อาหาร วัสดุยา อาหารสัตว์ ฯลฯ ได้ทุกชนิด วัสดุแปรรูปมีความละเอียดอ่อนและสวยงาม

หัวกัดดิสก์นี้มีโครงสร้างที่กะทัดรัด การทำงานที่ปลอดภัยและสะดวกสบาย รูปลักษณ์ที่สวยงาม การใช้พลังงานต่ำ ประสิทธิภาพที่มั่นคงและเชื่อถือได้ และได้รับความนิยมอย่างมากในหมู่ผู้ใช้

พลังของเครื่องบดอาจเป็นมอเตอร์ไฟฟ้าหรือเครื่องยนต์เบนซิน ลูกค้าสามารถเลือกกำลังได้ตามความต้องการ

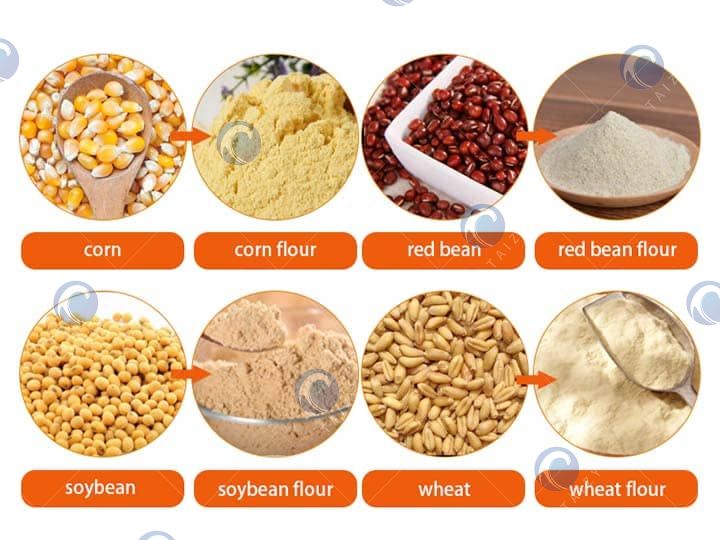

เครื่องจักรโรงสีดิสก์สามารถจัดการวัสดุใดได้บ้าง

เครื่องบดดิสก์เหมาะสำหรับการบดข้าวโพด ข้าวสาลี ถั่ว ฟาง เถาวัลย์ มันฝรั่งแห้งและสด พริกเปลือกใบแห้ง (สด) วัสดุยาจีน เมล็ดธัญพืช อาหารสัตว์ ฯลฯ

นอกจากนี้ยังสามารถบดแร่ที่มีความแข็งต่ำ เช่น ยิปซั่ม ผงตะกั่ว ผงสลิป ดินหายาก อุตสาหกรรมเคมี ดินเหนียว ถ่านหิน ฯลฯ ดังนั้นจึงเป็นอุปกรณ์ที่เหมาะสำหรับใช้ในเชิงพาณิชย์และในบ้าน

โครงสร้างของเครื่องโรงสีดิสก์

เครื่องจักรโรงสีดิสก์ส่วนใหญ่ประกอบด้วยหกส่วน: ตัวเครื่องส่วนบน ฝาครอบ ชุดโรเตอร์ หน้าจอ อุปกรณ์ป้อน และเฟรม ตัวเครื่องและชุดโรเตอร์รวมกันเป็นห้องบด ชุดโรเตอร์เป็นส่วนการทำงานหลัก การบดจะดำเนินการในห้องบด ตัวเครื่องมีขนาดเล็ก ใช้พื้นที่น้อย และประสิทธิภาพการทำงานสูง

หลักการทำงานของเครื่องโรงสีดิสก์คืออะไร?

เมื่อวัสดุเข้าสู่ห้องบด โครงสร้างคล้ายกรงเล็บจะบดขยี้เครื่องให้เป็นผงละเอียดและสารละลายอย่างรวดเร็วภายใต้การเป่าบางส่วน และยังนวดฟันทั้งกลมและแบนอีกด้วย จากนั้นจะถูกระบายออกทางรูตะแกรงภายใต้การกระทำของแรงเหวี่ยงและการไหลของอากาศ

เครื่องเจียรจานมีลักษณะโครงสร้างที่เรียบง่าย ติดตั้ง ใช้งานและบำรุงรักษาได้สะดวก และมีช่วงการใช้งานที่กว้าง

พารามิเตอร์ของเครื่องโรงสีดิสก์

| แบบอย่าง | 9FZ-280 |

| ความจุ | 300-500กก./ชม |

| น้ำหนัก | 60กก |

| ขนาด | 530*420*440มม |

เครื่องบดข้าวโพดทำงานอย่างไร?

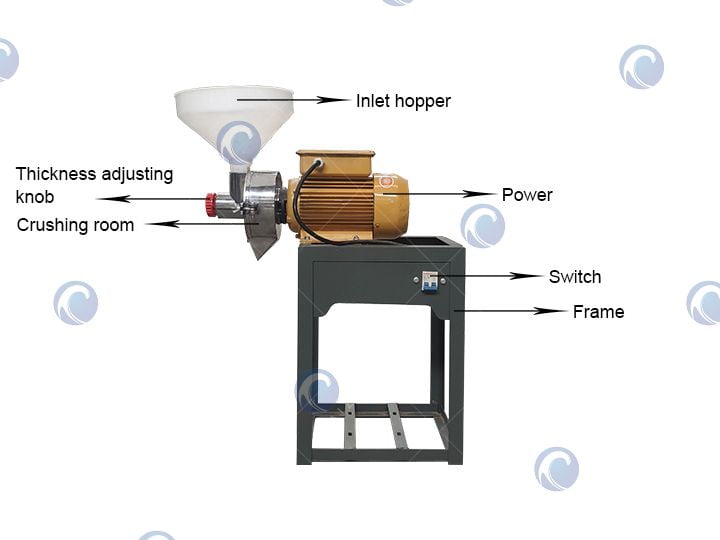

ประเภทที่ 2: เครื่องบดเมล็ดพืช

เครื่องบดเมล็ดพืชเป็นผลิตภัณฑ์ที่สามารถบดเมล็ดพืชให้เป็นผงหรือเมล็ดพืชที่ผ่านการแปรรูปเปียกให้เป็นเยื่อกระดาษ เครื่องบดเมล็ดพืชทรงพลังและสามารถแปรรูปแป้งข้าวเจ้า นมข้าว แป้ง แป้งข้าวโพด แป้งสาลี แป้งถั่วเหลือง ฯลฯ ได้ทุกชนิด

เครื่องมีลักษณะเฉพาะของการผลิตผงละเอียด การใช้งานแบบแห้งและแบบเปียก และความหนาที่ปรับได้ จึงสามารถตอบสนองความต้องการได้หลากหลาย นอกจากนี้ตัวเครื่องยังมีสวิตช์ไฟฟ้าป้องกันการรั่วซึมพร้อมประสิทธิภาพความปลอดภัยสูง

ส่วนประกอบของเครื่องบดโรงสีข้าว

เครื่องส่วนใหญ่ประกอบด้วยกรวยป้อนอาหาร, ปุ่มปรับความหนา, มอเตอร์, ทางออก, ตัวยึดหนา, สวิตช์และอื่น ๆ เครื่องบดเมล็ดพืชนี้มีขนาดกะทัดรัดและทนทานพร้อมประสิทธิภาพการทำงานสูง

โรงสีค้อนเมล็ดไฟฟ้ามีข้อดีอะไรบ้าง?

- เครื่องบดเมล็ดพืชมีอายุการใช้งานยาวนาน หัวหนา แผ่นเจียรเหล็ก ความบริสุทธิ์ของวัสดุสูง ความแข็งสูง และพื้นผิวละเอียด ซึ่งทำให้การเจียรละเอียดอ่อนยิ่งขึ้น

- ความละเอียดของผลิตภัณฑ์สำเร็จรูปสามารถปรับได้ ตัวเครื่องมีปุ่มปรับความหนาและลูกค้าสามารถปรับได้ตามความต้องการของตนเอง

- เครื่องจักรมีการใช้งานที่หลากหลายและสามารถแปรรูปอาหาร ยา และวัสดุอื่นๆ ได้หลากหลาย

- มอเตอร์กำลังสูง ใช้ลวดทองแดงอุณหภูมิสูง ตัวเครื่องจึงมีความทนทาน

- ขยายช่องทางให้หนาขึ้น แข็งแรง และมั่นคง

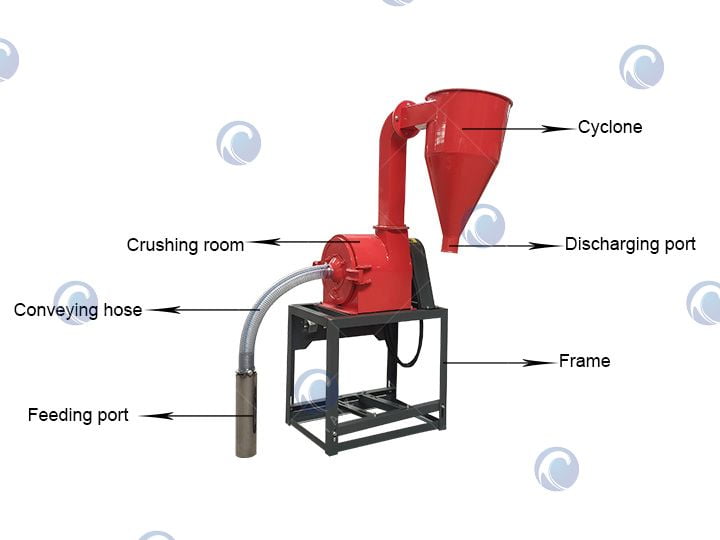

ประเภทที่ 3: เครื่องบดเมล็ดพืชด้วยไซโคลน

เครื่องบดเมล็ดพืชแบบมีไซโคลนเป็นเครื่องบดที่สามารถแปรรูปข้าว พริกแห้ง ยาสมุนไพรจีน เมล็ดธัญพืช อาหาร ฯลฯ ข้อแตกต่างระหว่างเครื่องบดเมล็ดพืชนี้กับแบบที่ 1 และแบบที่ 2 คือเครื่องนี้มีท่อที่สามารถดูดเมล็ดพืชได้ วัสดุด้วยตัวเองซึ่งช่วยประหยัดเวลาและความพยายาม

ความหนาของเครื่องบดยังสามารถเปลี่ยนแปลงได้ แต่จำเป็นต้องเปลี่ยนหน้าจอภายในเครื่อง นอกจากนี้เครื่องบดเมล็ดพืชรุ่นนี้ยังมีถังกำจัดฝุ่นซึ่งทำหน้าที่ดักจับฝุ่นเมื่อเครื่องจักรทำงานซึ่งเป็นประโยชน์ต่อสุขภาพของผู้คน

ส่วนประกอบของเครื่องสีเมล็ดพืชแบบไซโคลน

เครื่องบดเมล็ดพืชที่มีระบบไซโคลนส่วนใหญ่ประกอบด้วยช่องป้อนอาหาร สวิตช์ ท่อลำเลียง ห้องบด ช่องระบาย และถังกำจัดฝุ่นที่หนาขึ้น

คุณสมบัติของเครื่องบดเมล็ดพืชสำหรับเมล็ดพืชมีอะไรบ้าง?

- โครงสร้างที่เรียบง่าย ห้องบดค่อนข้างแคบ ปริมาตรมีขนาดเล็ก และน้ำหนักเบา

- มุมการพันของหน้าจอคือ 360 องศา ประสิทธิภาพการผลิตค่อนข้างสูงและความเร็วในการทำงานสูง

- ผลิตภัณฑ์มีขนาดอนุภาคละเอียดและสามารถปรับให้เข้ากับวัสดุแปรรูปได้กว้าง และสามารถนำมาใช้กันอย่างแพร่หลายในการบดเมล็ดพืช อาหารสัตว์ วัตถุดิบเคมี และยาสมุนไพรจีน

- เครื่องบดแบบ self-priming มีไซโคลนพร้อมฟังก์ชัน self-priming ซึ่งสามารถดูดวัตถุดิบเข้าไปในห้องบดได้โดยอัตโนมัติ ดังนั้นจึงช่วยเพิ่มอัตราการใช้วัตถุดิบและหลีกเลี่ยงของเสีย หลังจากการบด พายุไซโคลนสามารถป้องกันไม่ให้ผลิตภัณฑ์ถูกบดอัดกระจัดกระจายและกระเด็นได้อย่างมีประสิทธิภาพเพื่อให้แน่ใจว่าได้ผลลัพธ์จากการบด

การทำงานและการบำรุงรักษาเครื่องจักรอย่างปลอดภัย

- ก่อนสตาร์ทเครื่อง คุณต้องอ่านคู่มือการใช้งานอย่างละเอียด และดำเนินการปรับเปลี่ยนและบำรุงรักษาตามปกติ

- กำลังรองรับต้องเป็นไปตามข้อกำหนด และเราไม่ควรเพิ่มความเร็วของแกนหมุนโดยไม่ได้รับอนุญาต

- ก่อนสตาร์ทเครื่องควรตรวจสอบว่าทิศทางการทำงานเหมือนกับทิศทางการตัดหรือไม่ ไม่เช่นนั้น เราไม่ควรสตาร์ทเครื่อง

- วัสดุที่ต้องตัดไม่ควรผสมกับวัตถุแข็ง เช่น โลหะ และหิน มิฉะนั้นเครื่องจะเสียหายได้

- หลังจากที่เราสตาร์ทเครื่องได้ไม่กี่ชั่วโมงต้องสังเกตว่าชิ้นส่วนต่างๆหลวมหรือไม่และต้องเติมเนยอย่างสม่ำเสมอ

บทสรุป

เครื่องโม่ดิสก์ผสมผสานประสิทธิภาพ ความทนทาน และความอเนกประสงค์เข้าด้วยกัน ทำให้เป็นตัวเลือกที่เหมาะสำหรับการเจียรวัสดุหลากหลายประเภท ไม่ว่าคุณจะอยู่ในอุตสาหกรรมแปรรูปอาหาร ยา หรืออุตสาหกรรมเคมี เครื่องจักรนี้จะตอบสนองความต้องการของคุณและเพิ่มประสิทธิภาพการผลิตของคุณ

ติดต่อเราวันนี้เพื่อเรียนรู้เพิ่มเติมเกี่ยวกับเครื่องบดดิสก์และรับราคาล่าสุด เราหวังว่าจะได้เป็นพันธมิตรกับคุณและช่วยให้ธุรกิจของคุณก้าวไปสู่ระดับใหม่