เครื่องกะเทาะข้าวโพดสด丨อุปกรณ์เครื่องนวดข้าวโพดหวาน

เครื่องปอกเปลือกข้าวโพดสดเป็นอุปกรณ์ที่สามารถแยกเมล็ดข้าวโพดสดและซังข้าวโพดได้ เมล็ดข้าวโพดที่ผ่านการบำบัดสามารถนำไปแปรรูปเพิ่มเติมหรือแช่แข็งเพื่อทำอาหารแช่แข็งได้อย่างรวดเร็ว

เครื่องนวดข้าวโพดหวานใช้งานง่ายและมีประสิทธิภาพในการทำงานสูง และสามารถจัดการกับข้าวโพดสด ข้าวโพดหวาน ข้าวโพดข้าวเหนียว และข้าวโพดละลายได้ทุกชนิด

รู้เบื้องต้นเกี่ยวกับเครื่องปอกเปลือกข้าวโพดสด

เครื่องกะเทาะข้าวโพดสดของเราเป็นสแตนเลส 304 และตรงตามมาตรฐาน GMP และ USDA เครื่องสามารถรองรับข้าวโพดทุกขนาดและรูปทรง

เครื่องนี้มีด้วยกัน 2 รุ่น คือ HYMZ-268 และ HYMZ-368 ความแตกต่างระหว่างสองเครื่องคือการมีหรือไม่มีสายพานลำเลียงและเอาต์พุต เครื่องที่มีสายพานลำเลียงมีเอาต์พุตที่ใหญ่กว่า

ส่วนกำลังนั้นกำลังของเครื่องนวดข้าวโพดสดนี้คือมอเตอร์

นอกจากนี้ เครื่องแยกเมล็ดข้าวโพดยังมีพัดลม ซึ่งจะเป่าฝุ่นและสิ่งเจือปนออกจากเมล็ดข้าวโพด ดังนั้นผลิตภัณฑ์เมล็ดข้าวโพดที่ได้จึงสะอาดและสวยงาม นอกจากเครื่องนี้แล้ว เรายังมี เครื่องแยกเมล็ดข้าวและข้าวสาลี, เครื่องปอกข้าวโพด และ เครื่องผลิตเกล็ดข้าวโพด เป็นต้น.

เครื่องนวดข้าวโพดหวานมีประโยชน์อย่างไร?

เครื่องปอกเปลือกข้าวโพดสดนี้เหมาะสำหรับโรงงานแปรรูปอาหาร เช่น ครัวกลาง เมล็ดข้าวโพดกระป๋อง น้ำเชื่อมข้าวโพดแบบแช่แข็งอย่างรวดเร็ว โรงงานเมล็ดข้าวโพด การแปรรูปอาหารแห้ง การแปรรูปผลิตภัณฑ์ทางการเกษตรและผลิตภัณฑ์ปลีกย่อย ฯลฯ

โครงสร้างของเครื่องนวดข้าวโพดสด

เครื่องนวดข้าวโพดสดส่วนใหญ่ประกอบด้วยโครง, ล้อ, ลูกกลิ้งยาง, เครื่องนวดข้าว, ช่องเสียบเมล็ดข้าวโพด, พัดลม, ช่องเสียบซังข้าวโพด, ตู้ควบคุมไฟฟ้า ฯลฯ เครื่องปอกเปลือกข้าวโพดหวานมีขนาดเล็กรูปลักษณ์สวยงามและทำงานได้สูง ประสิทธิภาพ.

ยิ่งไปกว่านั้น วัสดุของเครื่องนวดข้าวโพดสดนี้คือสแตนเลส 304 และเมล็ดข้าวโพดหลังนวดข้าวจะสะอาดและถูกสุขลักษณะมากขึ้น และสามารถรับประทานได้อย่างมั่นใจ

ฟังก์ชั่นและคุณสมบัติของแต่ละส่วนของเครื่องกะเทาะข้าวโพดหวานมีอะไรบ้าง?

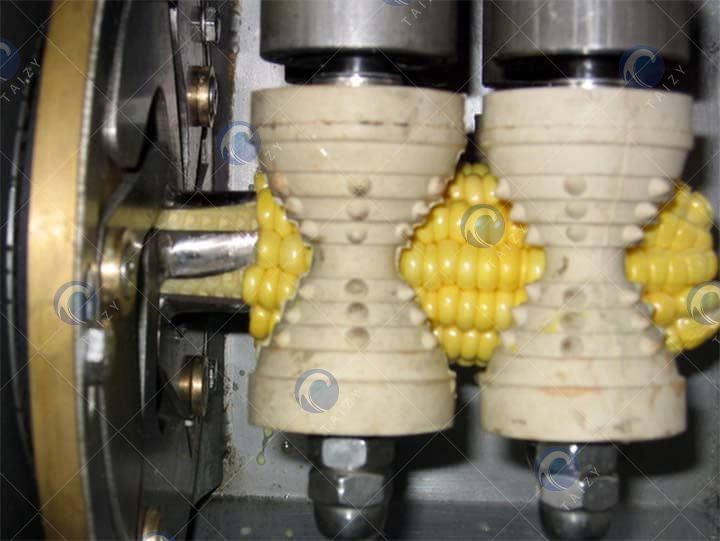

1.ลูกกลิ้งยาง

ฟังก์ชั่น: สามารถใช้แรงเสียดทานเพื่อส่งข้าวโพดเข้าไปในเครื่องนวดข้าวของตัวเครื่อง

คุณสมบัติ: เนื่องจากวัสดุยางค่อนข้างอ่อนและยืดหยุ่น จึงจะไม่ทำลายผิวเมล็ดข้าวโพดในระหว่างขั้นตอนการทำงาน ดังนั้นเมล็ดข้าวโพดจึงคงรูปร่างที่ดี

2. เครื่องนวดข้าว

ฟังก์ชั่น: ส่วนนี้สามารถตัดเมล็ดข้าวโพดออกจากซังข้าวโพดได้

คุณสมบัติ: ใบมีดของอุปกรณ์สามารถปรับได้ และเราสามารถปรับใบมีดตามเส้นผ่านศูนย์กลางของซังข้าวโพดที่เราจัดการได้ จึงสามารถจับข้าวโพดได้ทุกขนาด นอกจากนี้ วัสดุและการออกแบบของใบมีดยังได้รับการออกแบบมาเป็นพิเศษสำหรับการตัดที่เหมาะสม

3. เต้ารับซังข้าวโพด

ฟังก์ชั่น: ส่งซังข้าวโพดออกจากเครื่อง

คุณสมบัติ: ไกด์เกียร์ 4 ตัวสามารถนำทางซังข้าวโพดได้ ซึ่งสามารถหลีกเลี่ยงปรากฏการณ์ที่ซังข้าวโพดติดอยู่ในเครื่องได้อย่างมีประสิทธิภาพ

4. พัดลม

ฟังก์ชั่น: สามารถขจัดสิ่งสกปรกบนเมล็ดข้าวโพดได้อย่างมีประสิทธิภาพ

พารามิเตอร์ทางเทคนิคของเครื่องนวดข้าวข้าวโพดสด

| แบบอย่าง | แรงดันไฟฟ้า | มอเตอร์ | การผลิต | ขนาดสายพานลำเลียงอินพุต | ขนาดเครื่อง | น้ำหนักเครื่อง |

| HYMZ-268 | 220V 1 เฟส | 1HP+1/2HP+1/4HP | 400-500กก./ชม. (เมล็ดเท่านั้น) | ปราศจาก | 630*620*1250มม | 100กก |

| HYMZ-368 | 220V 1 เฟส | 1HP+1/2HP+1/4HP | 600กก./ชม.(เฉพาะเมล็ดพืช) | 690*260*380มม | 1320*620*1250มม | 100กก |

ขั้นตอนการทำงานของเครื่องนวดข้าวโพดแบบไฟฟ้าอัตโนมัติ

1. ขั้นแรก ให้เปิดเครื่องปอกเปลือกข้าวโพดสดหลังจากยืนยันว่าเครื่องใช้งานได้ปกติ วางฝักข้าวโพดไว้บนสายพานลำเลียงโดยหันเข้าหาเครื่อง หรือวางไว้บนอุปกรณ์ลูกกลิ้งยางโดยตรง

2. จากนั้นลูกกลิ้งยางจะส่งข้าวโพดเข้าไปในเครื่องนวดข้าวและใบมีดจะนวดข้าวโพด

3. จากนั้นเมล็ดข้าวโพดจะออกมาจากทางออก และเครื่องเป่าลมจะขจัดสิ่งสกปรกออกจากเมล็ดข้าวโพด

4. ขณะเดียวกัน ซังข้าวโพดก็จะถูกระบายออกจากอีกช่องทางหนึ่ง เครื่องก็ทำงาน

ข้อดีของเครื่องนวดข้าวข้าวโพดอุตสาหกรรมมีอะไรบ้าง?

1. วัสดุมีความปลอดภัย และเครื่องทั้งหมดทำจากสแตนเลส สะอาด และถูกสุขลักษณะ

2.เครื่องนวดข้าวโพดสดมีล้อซึ่งเคลื่อนย้ายได้ง่าย

3. ตัวแปลงความถี่ควบคุมความเร็วและการทำงานนั้นง่าย เหมาะสำหรับข้าวโพดสด หวาน เหนียวและข้าวโพดแช่แข็งทุกชนิดหลังการนวด

4. การปรับตัวที่แข็งแกร่ง ไม่เพียงแต่เหมาะสำหรับการผลิตขนาดใหญ่ในโรงงานที่มีสายการผลิตเท่านั้น แต่ยังเหมาะสำหรับการแปรรูปในโรงงานของครอบครัวด้วย

5. อัตราการใช้งานของเครื่องสูง เครื่องกะเทาะข้าวโพดสดสามารถปรับได้อัตโนมัติตามขนาดของซังข้าวโพด เหมาะสำหรับนวดข้าวโพดขนาดต่างๆ โดยมีอัตราการนวดสูง และความลึกของการนวดข้าวของเครื่องสามารถปรับได้ และอัตราการปอกเปลือกของข้าวโพดหวานสามารถเข้าถึง 100%

6. เครื่องมือมีอายุการใช้งานยาวนาน มีดของเครื่องนี้ทำจากวัสดุสแตนเลสชนิดพิเศษซึ่งไม่ต้องลับคมเป็นเวลานานและมีความทนทานมากกว่า

คำถามที่พบบ่อย

1. มีข้อกำหนดสำหรับเส้นผ่านศูนย์กลางของซังข้าวโพดหรือไม่?

ไม่มีข้อกำหนดใดๆ เนื่องจากสามารถปรับใบมีดของชุดนวดข้าวตามเส้นผ่านศูนย์กลางของซังข้าวโพดได้

2. HYMZ-268 และ HYMZ-368 แตกต่างกันอย่างไร?

368 มีสายพานลำเลียงอีกหนึ่งเส้นและเอาต์พุตก็ใหญ่ขึ้น

3. วัสดุของเครื่องปอกเปลือกข้าวโพดสดคืออะไร?

วัสดุสแตนเลส 304

4.พลังของเครื่องคืออะไร?

มอเตอร์.

5. ข้าวโพดเลี้ยงสัตว์ที่มีความยาวสั้นที่สุดคือเท่าใด?

80มม.