เครื่องกะเทาะถั่วลิสง | เครื่องปอกเปลือกถั่วลิสง

| แบบอย่าง | TBH-200 |

| ความจุ | 200กก./ชม |

| พลัง | มอเตอร์ 2.2kW, เครื่องยนต์เบนซิน 170F, เครื่องยนต์ดีเซล 6hp |

| น้ำหนัก | 40กก |

| ขนาด | 650*560*1000มม |

เครื่องปอกเปลือกถั่วลิสงขจัดเปลือกถั่วลิสงได้อย่างมีประสิทธิภาพ ทำให้มั่นใจได้ว่าเมล็ดไม่เสียหายและแตกหักน้อยที่สุด ทำงานที่ความจุตั้งแต่ 200 ถึง 800 กิโลกรัมต่อชั่วโมง โดยมีตัวเลือกกำลังที่หลากหลายและอัตราการกะเทาะสูง

ถั่วลิสงเป็นที่ต้องการอย่างมากเนื่องจากคุณค่าทางโภชนาการและการนำไปใช้ในผลิตภัณฑ์ต่างๆ เช่น เนยถั่วและน้ำมัน ความต้องการที่เพิ่มขึ้นทำให้จำเป็นต้องใช้วิธีการกะเทาะที่มีประสิทธิภาพ ทำให้เครื่องกะเทาะถั่วลิสงเป็นตัวเลือกที่ต้องการเนื่องจากมีประโยชน์ในการประหยัดแรงงาน

เครื่องกะเทาะถั่วลิสงที่ได้รับการรับรอง CE ของเรามีชื่อเสียงในด้านความน่าเชื่อถือและประสิทธิภาพในภูมิภาคต่างๆ เช่น เซเนกัล ไนจีเรีย เคนยา คองโก ซิมบับเว แกมเบีย และกรีซ ซึ่งตอบสนองความต้องการทางการเกษตรและอุตสาหกรรมที่หลากหลายได้อย่างมีประสิทธิภาพ

เครื่องกะเทาะถั่วลิสงที่ดีที่สุด

เรามีเครื่องกะเทาะถั่วลิสงหลายรุ่น บทความนี้จะแนะนำเครื่องกะเทาะถั่วลิสงรุ่นเล็กหลายรุ่นเป็นหลัก ได้แก่ TBH200, TBH400, TBH800, 6BHD-800D ส่วนใหญ่จะต่างกันในเรื่องผลผลิต ลูกค้าสามารถเลือกเครื่องที่เหมาะกับความต้องการของตนเองได้

นอกเหนือจากเครื่องปอกเปลือกถั่วลิสงขนาดเล็กเหล่านี้ เรายังมี ชุดปอกเปลือกถั่วลิสง ขนาดใหญ่กว่า ซึ่งสามารถปอกถั่วลิสงในปริมาณมากขึ้นได้.

เครื่องกะเทาะถั่วลิสงของเราได้รับการออกแบบมาเพื่อมอบประสิทธิภาพและประสิทธิผลที่โดดเด่น มาดูรุ่นเฉพาะที่เรานำเสนอกันดีกว่า

ประเภทที่ 1: เครื่องปอกเปลือกถั่วลิสง TBH200

เครื่องกะเทาะถั่วลิสงรุ่นนี้สามารถผลิตได้ 200กก./ชม. เครื่องจักรสามารถทำงานผ่านมอเตอร์ไฟฟ้า เครื่องยนต์เบนซิน หรือเครื่องยนต์ดีเซล ลูกค้าสามารถเลือกพลังงานที่ต้องการได้

เราจะติดตั้งเครื่องด้วยตะแกรง 2 ชิ้น โดยลูกค้าจะต้องเปลี่ยนตะแกรงที่แตกต่างกันตามขนาดของเมล็ดถั่วลิสง

ประเภทที่ 2: เครื่องปอกเปลือกถั่วลิสงอุตสาหกรรม TBH400

เครื่องกะเทาะถั่วลิสงนี้สามารถปอกเปลือกถั่วลิสงได้ 300-400 กิโลกรัมต่อชั่วโมง ขุมพลังของเครื่องเหมือนกับแบบที่ 1 มีหน้าจอให้เลือก 2 ขนาด ลูกค้าสามารถเลือกติดตั้งและใช้งานได้ตามความเหมาะสม

ประเภทที่ 3: เครื่องถอดเปลือกถั่วลิสง TBH800

เครื่องกะเทาะถั่วลิสงนี้มีท่อสีขาวและมีกลไกพัดลมที่ออกแบบมาสำหรับกระบวนการกะเทาะสองขั้นตอน หากถั่วลิสงไม่ได้รับการทำความสะอาดอย่างสมบูรณ์ระหว่างการปอกเปลือกครั้งแรก ถั่วลิสงจะเข้าสู่กระบวนการปอกเปลือกครั้งที่สอง ตัวเครื่องมีหน้าจอ 2 หน้าจอ คือหน้าจอที่ใหญ่กว่าและหน้าจอที่เล็กกว่าซึ่งต้องใช้พร้อมกันทั้งสองหน้าจอ

เมื่อถั่วลิสงถูกป้อนเข้าไปในเครื่อง ถั่วลิสงจะผ่านตะแกรงที่ใหญ่ขึ้นก่อนเพื่อเอาถั่วลิสงที่ปอกเปลือกออกทั้งหมด ในขณะที่ชิ้นถั่วลิสงที่ปอกเปลือกแล้วจะถูกระบายออกทางทางออก ถั่วลิสงที่เต็มไม่เต็มหรือปอกเปลือกไม่สะอาดจะดำเนินการผ่านกลไกพัดลมไปยังตะแกรงที่สองที่เล็กกว่าเพื่อการปอกเปลือกต่อไป

นอกจากนี้ เครื่องจักรยังทำงานบนเครื่องยนต์ดีเซล ไฟฟ้า และเบนซิน โดยให้แหล่งพลังงานที่ยืดหยุ่นเพื่อให้เหมาะกับความต้องการการปฏิบัติงานที่แตกต่างกัน

ประเภทที่ 4: เครื่องกะเทาะถั่วลิสง 6BHD-800D

เครื่องกะเทาะถั่วลิสงรุ่นนี้เหมือนกับแบบที่ 3 ทุกประการ อย่างไรก็ตาม เครื่องประเภทนี้สามารถติดตั้งชั้นวางและยางขนาดใหญ่ได้ ลูกค้าชาวแอฟริกันชอบเครื่องกะเทาะถั่วลิสงประเภทนี้

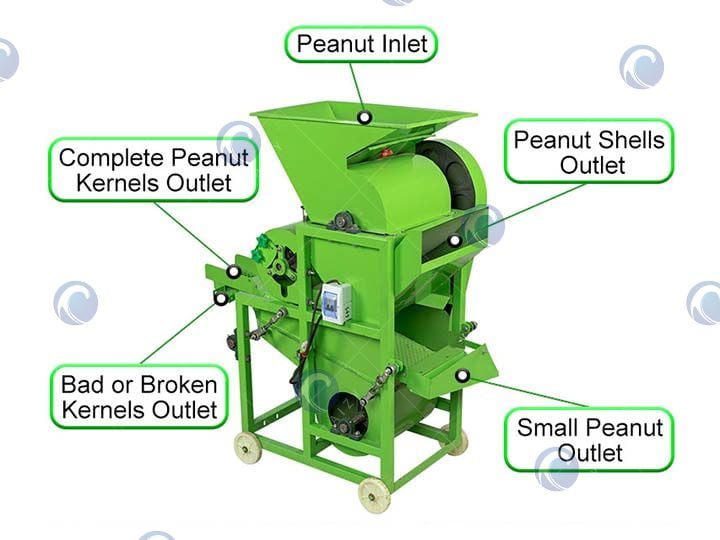

ต่อไป มาดูโครงสร้างของเครื่องกะเทาะของเราให้ละเอียดยิ่งขึ้น

โครงสร้างเครื่องถอดเปลือกถั่วลิสง

โครงสร้างหลักของเครื่องกะเทาะถั่วลิสงทั้งสามรุ่นนี้มีความคล้ายคลึงกัน ด้านล่างนี้คือโครงสร้างและรายละเอียดของรุ่น 400 เครื่องส่วนใหญ่ประกอบด้วยทางเข้า ทางออก ห้องปลอกกระสุน ฯลฯ

การทำความเข้าใจโครงสร้างช่วยในการชื่นชมการออกแบบและการทำงานของเครื่องจักรของเรา ต่อไป เราจะเจาะลึกถึงวิธีการทำงานของเครื่องจักรเหล่านี้

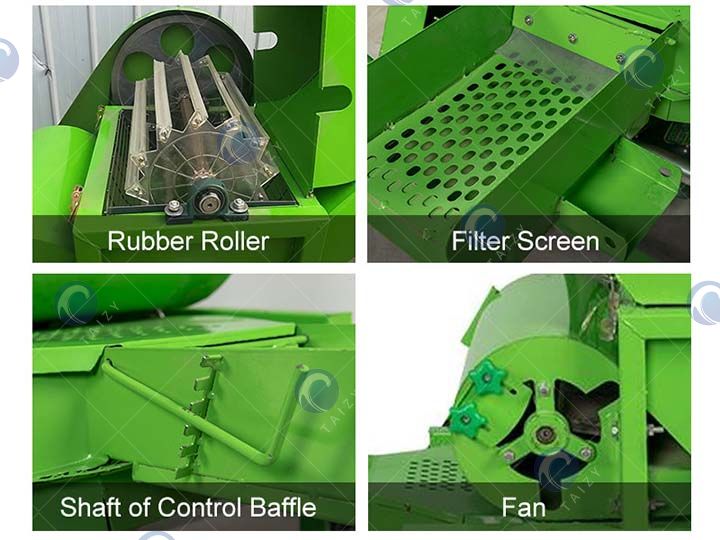

หลักการทำงานของเครื่องกะเทาะถั่วลิสง

เมื่อใช้งานแล้ว เครื่องกะเทาะถั่วลิสงจะป้อนถั่วลิสงลงในถังอย่างสม่ำเสมอและสม่ำเสมอ ภายในถั่วลิสงจะถูกกระแทก เสียดสี และการชนซ้ำๆ จากโรเตอร์ ทำให้ถั่วลิสงบดอย่างมีประสิทธิภาพ

หลังจากกระบวนการนี้ เมล็ดถั่วลิสงบดและเปลือกที่กระจัดกระจายจะถูกแยกออกจากกันผ่านตะแกรงที่มีช่องรับแสงที่แม่นยำภายใต้อิทธิพลของแรงลมที่หมุน เปลือกถั่วลิสงที่เบากว่าจะถูกไล่ออกจากเครื่อง ในขณะที่เมล็ดถั่วลิสงที่คัดแยกแล้วจะออกผ่านช่องทางอื่น โดยมีตะแกรงสั่นช่วยอำนวยความสะดวก

ในส่วนนี้จะอธิบายกระบวนการทางกลของการปอกเปลือก โดยเน้นที่ประสิทธิภาพของเครื่องจักรของเรา ตอนนี้ เรามาตรวจสอบพารามิเตอร์หลักกัน

พารามิเตอร์ของเครื่องปอกเปลือกถั่วลิสง

| แบบอย่าง | ความจุ | พลัง | น้ำหนัก | ขนาด |

| TBH-200 | 200กก./ชม | มอเตอร์ 2.2kW, เครื่องยนต์เบนซิน 170F, เครื่องยนต์ดีเซล 6hp | 40กก | 650*560*1000มม |

| TBH-400 | 300-400กก./ชม | มอเตอร์ 3kW, เครื่องยนต์เบนซิน 170F, เครื่องยนต์ดีเซล 8hp | / | / |

| TBH-800 | 600-800กก./ชม | มอเตอร์ 3kW, เครื่องยนต์เบนซิน 170F, เครื่องยนต์ดีเซล 8hp | 160กก | 1330*750*1570มม |

| 6BHD-800B | 600-800กก./ชม | มอเตอร์ 2.2-3.0kW | 160กก | 1330*750*1570มม |

พารามิเตอร์จะให้ภาพรวมทางเทคนิคโดยละเอียดเกี่ยวกับความสามารถของแต่ละรุ่น ก้าวต่อจากนี้ เรามาเน้นย้ำถึงข้อดีของการใช้อุปกรณ์ถอดเปลือกของเรากัน

ข้อดีของการขจัดเปลือกถั่วลิสง

- ผลผลิตสูง- เครื่องนี้รับประกันการกะเทาะที่สะอาดด้วยช่วงเอาต์พุตที่น่าประทับใจ 200-800 กก./ชม. ลูกค้าสามารถเลือกรุ่นที่ตรงกับความต้องการของตนเองได้มากที่สุด

- อัตราการสูญเสียต่ำ- ออกแบบมาเพื่อลดการสูญเสียเคอร์เนลให้เหลือน้อยที่สุด เครื่องจักรจะรักษาอัตราการสูญเสียที่ต่ำ เพื่อให้ได้ผลผลิตสูงสุด

- การบดน้อยที่สุด- เครื่องกะเทาะมีอัตราการบดเล็กน้อย ช่วยรักษาความสมบูรณ์ของเมล็ดถั่วลิสง

- โครงสร้างที่เรียบง่ายและเชื่อถือได้- โครงสร้างของมันตรงไปตรงมา เชื่อถือได้ และปรับเปลี่ยนได้ง่าย ทำให้ใช้งานง่ายและมีประสิทธิภาพ

- การทำงานที่หลากหลาย- เหมาะสำหรับถั่วลิสงทั้งแห้งและเปียก ให้ความยืดหยุ่นในการใช้งาน อย่างไรก็ตาม ถั่วลิสงที่แห้งมากเกินไปอาจส่งผลให้อัตราการบดสูงขึ้น ในขณะที่ถั่วลิสงที่เปียกมากเกินไปอาจส่งผลต่อประสิทธิภาพ

การทราบถึงข้อดีจะช่วยในการตัดสินใจอย่างมีข้อมูลรอบด้านเกี่ยวกับผลิตภัณฑ์ของเรา ตอนนี้เรามาดูกรณีศึกษาที่ประสบความสำเร็จเพื่ออธิบายเรื่องนี้กัน

เครื่องกะเทาะถั่วลิสงอัตโนมัติขายให้กับสหรัฐอเมริกา

ลูกค้าเป็นคนงานเนยถั่วในสหรัฐอเมริกา เขาติดต่อเราโดยเข้าไปดูที่หน้าเครื่องปอกเปลือกถั่วลิสงของเรา ผู้จัดการฝ่ายขายของเราติดต่อลูกค้าทันที จากการสื่อสาร เราได้เรียนรู้ว่าลูกค้าเคยซื้อเมล็ดถั่วลิสงโดยตรงเพื่อแปรรูปเป็นเนยถั่วมาก่อน

ช่วงนี้ลูกค้าต้องการปอกเปลือกถั่วลิสงเอง ตามความต้องการด้านผลผลิตของลูกค้า เราขอแนะนำเครื่องกะเทาะถั่วลิสงรุ่น TBH400 เนื่องจากเครื่องจักรอยู่ในงบประมาณของลูกค้า ลูกค้าจึงสั่งซื้อเครื่องกะเทาะถั่วลิสงทันทีหลังจากข้อมูลทั้งหมดได้รับการยืนยัน นี่คือภาพการบรรจุและการจัดส่งของเครื่อง

ติดต่อเรา!

ตอนนี้เมื่อคุณทราบถึงข้อดีหลายประการของเครื่องปอกเปลือก ถั่วลิสง ของเรา—ตั้งแต่ประสิทธิผลสูงและอัตราการสูญเสียน้อยไปจนถึงการบดทำน้อย โครงสร้างที่เรียบง่ายและเชื่อถือได้ และการใช้งานที่หลากหลาย—เครื่องของเราไม่มีข้อสงสัยว่าเป็นตัวเลือกที่ดีที่สุดเพื่อตอบสนองความต้องการของคุณ.

ไม่ว่าฟาร์มของคุณจะใหญ่หรือเล็ก เรามีโมเดลที่เหมาะสมเพื่อช่วยคุณเพิ่มประสิทธิภาพและผลผลิต อย่าลังเลอีกต่อไป ติดต่อเราวันนี้เพื่อขอข้อมูลเพิ่มเติมและใบเสนอราคา และมาร่วมเดินทางสู่การปลอกกระสุนอย่างมีประสิทธิภาพไปด้วยกัน!