เครื่องบดโรงสีค้อน | เครื่องบดข้าวโพด

| แบบอย่าง | 9FQ-360 |

| พลัง | 5.5kw |

| น้ำหนัก | 130กก |

| ความจุ | 600กก./ชม |

| ค้อน | 12 ชิ้น |

| ขนาด | 1200*600*1100มม |

เครื่องบดหัวค้อนบดฟางและธัญพืชให้เป็นอนุภาคละเอียดด้วยประสิทธิภาพสูง มันสามารถประมวลผลวัสดุหลากหลาย รวมถึงฟาง หญ้า forage และข้าวโพด มีโมเดลหลายรุ่นในซีรีส์นี้ และแต่ละรุ่นให้ผลผลิตที่แตกต่างกันเพื่อให้เหมาะกับความต้องการในการผลิตเฉพาะ.

ในแง่ของกำลัง เครื่องบดข้าวโพดสามารถติดตั้งกำลังได้สามประเภท: มอเตอร์ไฟฟ้า เครื่องยนต์ดีเซล และเครื่องยนต์เบนซิน ลูกค้าสามารถเลือกได้ตามความต้องการ

วัสดุใดบ้างที่เหมาะสำหรับเครื่องบดโรงสีข้าว?

เครื่องบดโรงสีข้าวเหมาะสำหรับการประมวลผลวัสดุหลากหลาย มันสามารถบดธัญพืช เช่น ข้าวโพด ข้าวสาลี ข้าว และถั่วเหลือง รวมถึงข้าวฟ่างให้เป็นผงละเอียดหรืออนุภาคหยาบตามต้องการ.

นอกจากธัญพืชแล้ว ยังสามารถจัดการกับผลพลอยได้ทางการเกษตร เช่น ฟาง ก้าน และเปลือกหุ้มเมล็ดพืช ทำให้เหมาะสำหรับการเตรียมอาหารสัตว์และการประมวลผลชีวมวล ความหลากหลายนี้ช่วยให้เครื่องสามารถให้บริการในอุตสาหกรรมต่าง ๆ รวมถึงการผลิตอาหาร การเลี้ยงสัตว์ และการผลิตเชื้อเพลิงชีวมวล.

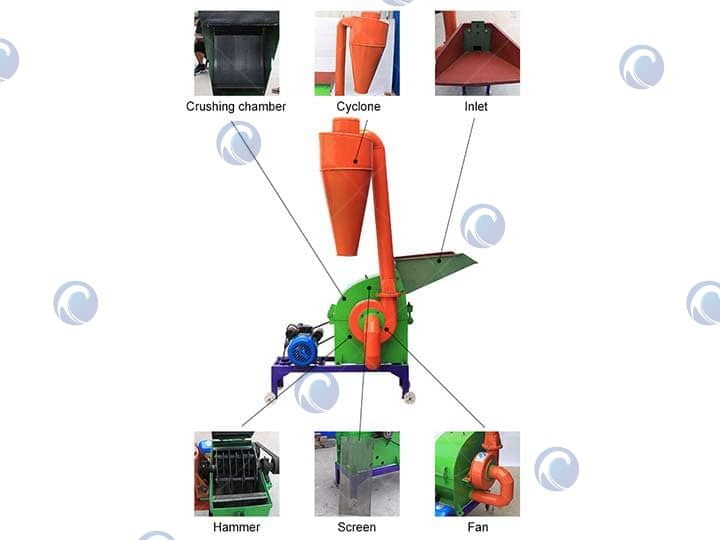

โครงสร้างของเครื่องบดโรงสีค้อน

- ฐาน: ให้ความมั่นคงระหว่างการทำงาน

- โรเตอร์: ขับเคลื่อนการเคลื่อนที่ของค้อนเพื่อการบดที่มีประสิทธิภาพ

- เครื่องป้อน: แนะนำวัตถุดิบเข้าเครื่อง

- ห้องบด: คุณสมบัติค้อนเหล็กคาร์บอนสูงทนทานเพื่อการบดที่มีประสิทธิภาพ

- หน้าจอ: ปรับแต่งได้เพื่อควบคุมขนาดอนุภาคของผลิตภัณฑ์ขั้นสุดท้าย

- พายุไซโคลน: รวบรวมและปล่อยวัสดุแปรรูปอย่างมีประสิทธิภาพ ลดฝุ่น

เครื่องบดโรงสีข้าวทำงานอย่างไร?

- การป้อนวัสดุ- วัตถุดิบจะถูกนำเข้าไปในห้องบดผ่านทางตัวป้อนเพื่อควบคุมอินพุต

- การบดด้วยความเร็วสูง- ค้อนหมุนจะทำลายวัสดุอย่างรวดเร็วผ่านการกระแทกและการบด

- การคัดกรองและการจำหน่าย- วัสดุที่ถูกบดจะผ่านตะแกรง ซึ่งเป็นตัวกำหนดขนาดขั้นสุดท้าย จากนั้นจึงระบายออกทางทางออก

พารามิเตอร์ของเครื่องบดแบบค้อน

| แบบอย่าง | พลัง | น้ำหนัก | ความจุ | ค้อน | Dia ของตะแกรง | ขนาด(มิลลิเมตร) |

| 9FQ-320 | 2.2kw | 85กก | 200กก./ชม | 12 ชิ้น | 0.5-5มม | 1200*500*1000 |

| 9FQ-360 | 5.5kw | 130กก | 600กก./ชม | 12 ชิ้น | 0.5-5มม | 1200*600*1100 |

| 9FQ-420 | 7.5/11กิโลวัตต์ | 220กก | 1,000กก./ชม | 16 ชิ้น | 1.2-3มม | 1500*800*1400 |

| 9FQ-500 | 11/15กิโลวัตต์ | 270กก | 1500กก./ชม | 16 ชิ้น | 1.2-3มม | 1500*1000*1600 |

ข้อดีของเครื่องบดป้อนโรงสีค้อนคืออะไร?

- การใช้งานกว้าง: บดธัญพืช ถั่วเมล็ดพืช ฟาง หญ้า ชิปไม้ และชีวมวลอื่น ๆ สำหรับใช้เป็นอาหาร เลี้ยงสัตว์ หรือเชื้อเพลิง.

- การบดที่มีประสิทธิภาพสูง: ติดตั้งใบมีดหัวค้อนความเร็วสูง 24 ใบสำหรับการบดละเอียดและสม่ำเสมอ.

- ปรับขนาดผลผลิตได้: ตะแกรงหน้าจอเปลี่ยนได้ช่วยให้ควบคุมขนาดอนุภาคได้อย่างยืดหยุ่น.

- ปล่อยฝุ่นป้องกัน: ช่องออกแบบไซโคลนช่วยลดการกระจายของผงและรักษาความสะอาดในพื้นที่ทำงาน.

- ทนทานและใช้งานง่าย: โครงสร้างแข็งแรงรับประกันประสิทธิภาพที่เสถียร พร้อมการใช้งานและบำรุงรักษาที่ง่าย.

โรงสีค้อนความจุสูงสำหรับขายในแองโกลา

ลูกค้าซึ่งตั้งอยู่ในแองโกลา เชี่ยวชาญด้านการเลี้ยงโคและแกะ และค้นหาเครื่องจักรเพื่อปรับปรุงประสิทธิภาพและประหยัดเวลา หลังจากหารือเกี่ยวกับข้อกำหนดเฉพาะแล้ว ผู้จัดการฝ่ายขายที่มีประสบการณ์ของเราได้แนะนำโรงสีค้อนขนาด 500 เพื่อให้มั่นใจว่าโซลูชันที่ออกแบบโดยเฉพาะจะตรงกับความต้องการในการปฏิบัติงานของพวกเขา

ด้วยความประทับใจในความเป็นมืออาชีพของเราและการสนับสนุนที่ครอบคลุม ลูกค้าจึงตัดสินใจซื้อโรงสีค้อนรุ่น 500 อย่างมั่นใจ เครื่องได้รับการบรรจุอย่างพิถีพิถันเพื่อความปลอดภัยในการขนส่งและส่งถึงมือลูกค้าทันที ด้านล่างนี้คือการแสดงภาพบรรจุภัณฑ์อย่างระมัดระวังและกระบวนการจัดส่งที่ตรงเวลา

คำถามที่พบบ่อยของ โรงสีค้อน เครื่องบด

1. เครื่องบดโรงสีค้อนนี้สามารถจัดการวัสดุอะไรได้บ้าง?

สามารถจับฟาง อาหารสัตว์ ข้าวโพดซัง ข้าวโพด ฯลฯ

2.พลังของเครื่องคืออะไร?

มอเตอร์ไฟฟ้า เครื่องยนต์ดีเซล และเครื่องยนต์เบนซิน

3. สามารถปรับแต่งหน้าจอของเครื่องบดโรงสีค้อนได้หรือไม่?

ใช่ ลูกค้าต้องแจ้งความต้องการล่วงหน้า

4.ตัวเครื่องมีตัวเก็บฝุ่นหรือไม่?

ยกเว้นรุ่น 320 รุ่นอื่นๆ ทั้งหมดมีไซโคลน

ติดต่อเราตอนนี้!

เครื่องบดโรงสีหัวค้อนนำเสนอวิธีแก้ปัญหาที่ทรงพลังและมีประสิทธิภาพสำหรับการประมวลผลวัสดุหลากหลาย ตั้งแต่ธัญพืชและถั่วเมล็ดพืช ไปจนถึงฟาง ก้าน และชิปไม้ นอกจากนี้ยังสามารถใช้ร่วมกับ เครื่องตัดฟาง และ เครื่องห่อหุ้มฟาง เป็นชุดสมบูรณ์สำหรับการประมวลผลอาหารสัตว์.

ติดต่อเราวันนี้เพื่อรับใบเสนอราคาที่ปรับแต่งได้และค้นหาโมเดลที่เหมาะสมกับความต้องการในการผลิตของคุณ!