15TPD مشترکہ خودکار چاول کی ملنگ مشین

| ماڈل | MNMS15B |

| صلاحیت (t/h) | 0.8-1.25 |

| پاور (کلو واٹ) | 18.5-22 |

| سائز (L*W*H) | 1090*580*1420mm |

15TPD مشترکہ خودکار چاول کی ملنگ مشین ایک موثر اور کمپیکٹ پیداواری لائن ہے جو چھوٹے سے درمیانے درجے کی چاول کی پروسیسنگ کے لیے ڈیزائن کی گئی ہے۔ یہ یونٹ ضروری چاول کی ملنگ کی فعالیتوں جیسے کہ چاول کی صفائی، پتھر نکالنا، چھلکا اتارنا، علیحدگی، ملنگ، اور گریڈنگ کو ایک مکمل نظام میں یکجا کرتا ہے۔

روزانہ 15 ٹن کی پروسیسنگ کی صلاحیت کے ساتھ، یہ کم سے کم مزدوری کی شمولیت کے ساتھ اعلیٰ پیداوار کو یقینی بناتا ہے۔ دیہی چاول کی ملوں، زرعی تعاون سوسائٹیوں، اور چھوٹے پروسیسنگ پلانٹس کے لیے مثالی۔

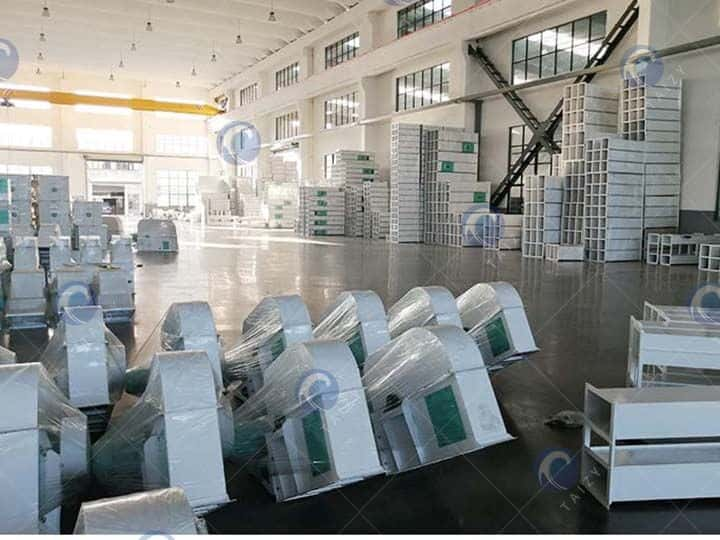

15TPD خودکار چاول ملنے والی مشین برائے فروخت

خودکار چاول کی ملنگ کی مشینیں بھورے چاول کو سفید چاول میں مؤثر طریقے سے تبدیل کرتی ہیں، خاص طور پر لمبے دانے کی اقسام کے لیے ان کے ایمرے رولرز کی بدولت۔ ہمارے ماڈلز—MNMS15B، MNMS18، اور MNMS25—مختلف گھنٹہ وار صلاحیتیں پیش کرتے ہیں تاکہ مختلف پیداوار کی ضروریات کو پورا کیا جا سکے۔

کمپیکٹ اور موثر، یہ کم ٹوٹ پھوٹ کی شرح اور مؤثر چورا علیحدگی کو یقینی بناتے ہیں۔ جب انہیں ایک مشترکہ چاول کی ملنگ لائن میں استعمال کیا جاتا ہے، تو متعدد مشینوں کو آپ کی مخصوص ضروریات کی بنیاد پر زیادہ پیداوار اور بہتر ملنگ کی کارکردگی کے لیے ترتیب دیا جا سکتا ہے۔

چاول ملنے والی مشین کا ڈھانچہ

خودکار چاول کی گھسائی کرنے والی مشین میں ایک ہوپر، ایمری رولر، چھلنی، ہینڈل، وزن، ایئر کلیئر، آؤٹ لیٹ وغیرہ شامل ہیں۔

چاول کی ملنگ مشین کے ہر حصے کا کام

- ہوپر. بھورے چاول کو اس انلیٹ کے ذریعے مشین میں لوڈ کیا جاتا ہے۔

- ایمری رولر اور چھاننے والا. چاول کو ملنگ کے دوران ایمرے رولر اور اسکرین کے درمیان رگڑنے سے پیسا جاتا ہے، اور چھلکا چھلکے کے ذریعے گرتا ہے۔

- ہینڈل. ملنگ چیمبر میں بھورے چاول کی مقدار کو کنٹرول کرنے کے لیے استعمال ہوتا ہے۔

- وزن. چاول کی ملنگ کی ڈگری کو کنٹرول کرنے کے لیے ملنگ کے دباؤ کو ایڈجسٹ کریں۔

- ہوا صاف کرنے والا. مشین سے الگ شدہ چاول کے چھلکے کو باہر پھینکتا ہے۔

- آؤٹ لیٹ. پروسیس شدہ سفید چاول اس ایگزٹ کے ذریعے خارج کیا جاتا ہے۔

چاول ملنے والی مشین کیسے کام کرتی ہے؟

- کھانا کھلانے والا ہاپر. بھورے چاول کو فیڈنگ ہوپر کے ذریعے مشین میں متعارف کرایا جاتا ہے۔

- پیچ کا سر. چاول کو وائٹننگ چیمبر میں رہنمائی کرتا ہے اور اسے ایمرے رولر کی طرف لے جاتا ہے۔

- ایمری رولر. جب چاول گھومتے ہوئے رولر کے ساتھ گھومتا ہے، تو رگڑنے والی سطح چھلکے کی تہہ کو پیس دیتی ہے۔

- ہوا پھونکنے والایہ ایک ساتھ کام کرتا ہے تاکہ چاول سے چھلکا پاؤڈر الگ کرنے میں مدد مل سکے۔

- چھاننے والایہ چھلکے کو چیمبر سے باہر نکالنے کی اجازت دیتا ہے، جس سے صاف، سفید چاول باقی رہ جاتا ہے۔

کے پیرامیٹرز چاول کی چکی مشین

| ماڈل | صلاحیت (t/h) | پاور (کلو واٹ) | سائز (L*W*H) |

| MNMS15B | 0.8-1.25 | 18.5-22 | 1090*580*1420mm |

| MNMS18 | 2-3 | 22-30 | 1245*650*1660 ملی میٹر |

| MNMS25 | 3.5-4.5 | 37-45 | 1350*750*1800 ملی میٹر |

فروخت کے لیے چاول کی گھسائی کرنے والی مشین کی خصوصیات

- یہ مشین اعلیٰ معیار کے چاول تیار کرتی ہے جس میں چاول کے چھلکے کی صاف علیحدگی ہوتی ہے۔

- تیار شدہ چاول سفید، چمکدار، کم درجہ حرارت پر ہوتا ہے، اور اس میں کم ٹوٹنے کی شرح ہوتی ہے، جو اسے طویل مدتی ذخیرہ کرنے کے لیے موزوں بناتی ہے۔

- اس میں کمپیکٹ ڈیزائن، اعلیٰ کارکردگی، اور سادہ آپریشن کی خصوصیات ہیں۔

- طاقتور ہوا کے بہاؤ کا نظام روایتی ماڈلز کے مقابلے میں ہوا کی مقدار کو دوگنا فراہم کرتا ہے، جس کے نتیجے میں چاول کا درجہ حرارت کم اور ملنگ کی کارکردگی زیادہ ہوتی ہے۔

- پیچھے نصب موٹر اور بیلٹ ٹینشننگ ڈیوائس سے لیس، اسے ایڈجسٹ اور برقرار رکھنا آسان ہے۔

- ایمری رولرز، آئرن رولرز، یا دونوں کے ملاپ کے ساتھ ہم آہنگ، یہ زیادہ پیداوار، کم توانائی کی کھپت، اور بہتر کارکردگی کے ساتھ کثیر مرحلہ وائٹننگ کی حمایت کرتا ہے۔

بلا جھجھک ہم سے رابطہ کریں!

آخر میں، ہماری خودکار چاول کی گھسائی کرنے والی مشینیں چاول کی پروسیسنگ میں بے مثال کارکردگی اور درستگی پیش کرتی ہیں۔ معیار اور اختراع کے لیے ہماری وابستگی کے ساتھ، ہم اس بات کو یقینی بناتے ہیں کہ ہر یونٹ بہترین کارکردگی اور قابل اعتماد فراہم کرے۔ مزید برآں، ہم مختلف پیداواری صلاحیتوں کو پورا کرنے والے رائس مل ماڈلز کی ایک رینج پیش کرتے ہیں۔

چاہے آپ کو کم ظرفیتی یونٹ درکار ہو یا بڑے پیمانے پر چاول پیسنے کا حل, ہمارے پاس آپ کی ضروریات کو پورا کرنے کے لیے مہارت اور ٹیکنالوجی موجود ہے۔ مزید جاننے اور قیمت معلوم کرنے کے لیے آج ہی ہم سے رابطہ کریں۔