Máy xay xát gạo tự động tích hợp 60T/D

Giới thiệu máy xay xát gạo 60T/D

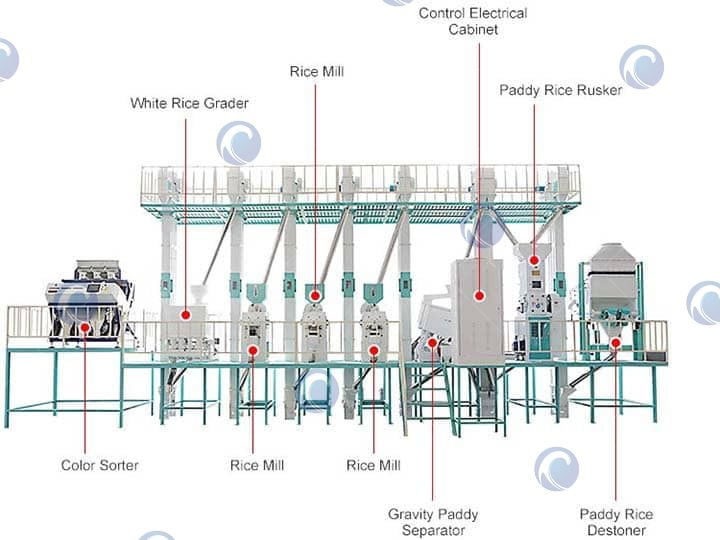

Máy xay xát gạo tự động tích hợp 60T/D là thiết bị có thể chế biến thóc thành gạo. Phiên bản cơ bản của máy xay xát gạo 60T/D bao gồm máy sàng liên hợp, máy tách đá, máy trấu, máy tách thóc trọng lực, máy xay gạo và máy phân loại gạo. Ngoài ra còn có thể bổ sung thêm các loại máy móc tương đối khác để kết hợp thành dòng sản phẩm hoàn thiện hơn. Chẳng hạn như máy xay gạo bằng nước, máy phân loại màu và máy đóng gói, tiết kiệm thời gian hơn, tiết kiệm năng lượng hơn và hiệu quả cao hơn, v.v. Máy xay gạo này có ưu điểm là vận hành dễ dàng, bảo trì đơn giản, nhiệt độ gạo thấp, v.v. Và thiết bị này phù hợp với tất cả các loại ngũ cốc thô ở các vùng khác nhau. Ngoài ra chúng tôi còn có công suất nhỏ máy xay lúa. Và những chiếc máy này chỉ có chức năng xay xát gạo.

Cấu trúc của nhà máy xay lúa trọn bộ 60T/D

Nó bao gồm máy sàng liên hợp, máy tách đá, máy xay trấu, máy tách thóc trọng lực, máy xay xát gạo, máy phân loại gạo.

Chức năng từng bộ phận của máy xay xát gạo tích hợp

- Lọc tổng hợp: chủ yếu loại bỏ các tạp chất như rơm rạ, cành cây và các tạp chất nhỏ hơn có trong thóc.

- Loại bỏ đá: làm sạch những viên đá nhỏ và mảnh vụn có trọng lượng riêng lớn trong gạo để tránh làm hỏng thiết bị chế biến gạo.

- Husker: bỏ vỏ gạo. Gạo được chế biến thành gạo lứt.

- Máy tách thóc trọng lực: có thể sàng gạo thành gạo lứt, hỗn hợp gạo lứt và thóc, thóc. Và thóc sẽ lại vào máy xay.

- Máy xay gạo: chế biến gạo lứt thành gạo trắng mịn.

- Máy phân loại gạo: Lấy toàn bộ gạo thành 3 loại. Một là gạo nguyên hạt lớn. Thứ hai là gạo nguyên hạt nhỏ. Và thứ ba là cơm tấm.

Quy trình làm việc của máy xay xát gạo tổ hợp 60T/D

- Đầu tiên là cho thóc vào phễu của thang máy.

- Thứ hai, thóc cho vào máy tách đá để loại bỏ đá khỏi thóc.

- Tiếp theo vào máy xay để loại bỏ vỏ thóc.

- Sau đó, nó đi vào máy tách thóc, gạo còn nguyên vỏ lại được đưa đến máy tách vỏ. Và gạo lứt được đưa vào máy xay xát gạo.

- Sau đó nhập trình chấm điểm.

Thông số dây chuyền sản xuất máy xay xát gạo tự động

| Máy móc | Công suất (t/h) | Tốc độ quay (vòng/phút) | Công suất(kw) | Thể tích hút(m³/h) |

| Kết hợp rõ ràng hơn | 6-7 | 920 | 2*0.37 | 4800 |

| Chất tẩy đá | 6-7 | 185+_15 | 0.75 | 3800-4200 |

| Trấu | 4.2-5 | Nhanh(1228-1673)Chậm(1108-1362) | 7.5 | 3200-3800 |

| Máy tách thóc trọng lực | 3.4-4 | 255+_15 | 1.5 | |

| Nhà máy xay lúa | 2-3 | 1290 | 22-30 | 3500-3800 |

| Máy phân loại gạo | 2.5-3.5 | 150+_15 | 1.1 | |

| Thang máy | 2.4-3.5 | 189 | 1.1 | 300 |

Các tính năng của máy xay xát gạo công suất cao 60T/D:

1. Dây chuyền sản xuất này phù hợp để bổ sung nhiều loại gạo khác nhau, có nhiều ứng dụng, năng suất lúa cao và tỷ lệ gạo vỡ thấp.

2. Nhiều máy xay xát gạo có thể tạo ra gạo có độ chính xác cao và chất lượng cao, phù hợp hơn với nhu cầu kinh doanh.

3. Nó được kết hợp với một màn hình làm sạch và máy loại bỏ đá riêng biệt, hiệu quả loại bỏ tạp chất và đá là tốt hơn.

4. Bạn cũng có thể lắp đặt một máy đánh bóng để làm cho gạo trong hơn và có chất lượng tốt hơn.

5. Sử dụng lưới hút khí bên ngoài để giảm ô nhiễm bụi và cải thiện môi trường làm việc.

6. Có quy trình kỹ thuật hoàn chỉnh và bộ thiết bị sản xuất đầy đủ, bao gồm làm sạch, loại bỏ đá, bóc vỏ, xay xát gạo, phân loại, đánh bóng, phân loại màu sắc, lựa chọn, cân tự động, đóng gói, v.v.

Đóng gói và vận chuyển máy xay xát gạo