玉米、小米、高粱、大豆自动多粒脱粒机

| 模型 | MT-860 |

| 容量 | 1.5-2吨/小时 |

| 尺寸 | 1150*860*1160mm |

| 脱粒率 | 98% |

| 车轮 | 四 |

| 重量 | 112公斤 |

| 力量 | 汽油机 |

多功能脱粒机 适用于多种谷物和豆类的农业加工机械,包括玉米、小米、高粱和大豆。它通过自动将谷粒从穗壳和杂质中分离出来,显著减少人工劳动,提高收获效率,几乎无需投入。

产品主要有两种型号——MT-860和MT-1200——容量分别约为1.5–2吨/小时和3吨/小时。两者都实现了约98%的高脱粒率,操作简便,配备可更换的筛网以适应不同作物,可由汽油或柴油发动机驱动。

出售商用多功能脱粒机

这款商用多功能脱粒机旨在满足多样化谷物加工需求,将多种作物的脱粒功能集成于一体,紧凑型设计。

只需更换内部筛网,设备即可适应不同粒径的谷物,确保在操作过程中干净分离和顺畅排放。例如,在加工玉米时,安装较大的筛网,以便谷粒能高效通过而不堵塞或损坏。

为了适应不同工作条件,机器提供 灵活的动力配置 ,包括电动机、柴油机和汽油机选项。这使得在有电网的地区和偏远农场都能稳定运行。在脱玉米时,机器可以处理带壳或不带壳的材料,提升适应性,减少预处理需求。

为商业效率而设计的多功能脱粒机,能在最小化劳动投入和能耗的同时,提供高产量。提供两种型号——MT-860和MT-1200——每种具有不同的处理能力和结构尺寸,用户可根据生产规模、作物类型和产量预期选择最合适的方案。

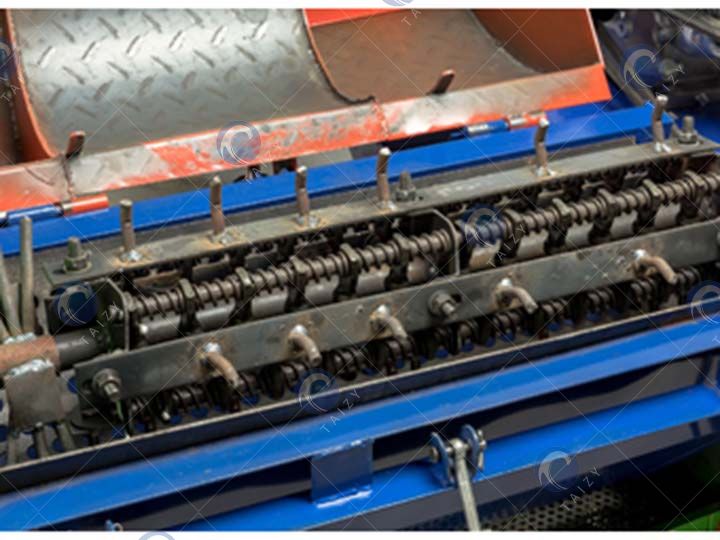

玉米脱粒机的结构

多粒脱粒机主要包括进料口、脱粒装置、引风机、杂质出口、轻杂出口、谷物出口等。

脱粒装置的内部结构

该部件包括筛筒锤。当我们加工不同的谷物时,我们应该更换不同大小的麦芽浆的筛网。而且操作简单。

玉米剥壳机是如何工作的?

- 将谷物喂入 多粒脱粒机 通过进料口。

- 谷物进入脱粒室后,被冲击 高速旋转锤片筒破碎并脱粒材料的

- 脱粒后的谷粒通过 筛孔根据大小分离谷粒和残渣。

- 清洁的谷粒和杂质被排出 从不同出口完成脱粒和分离过程。

待售谷物脱粒机的技术参数

| 模型 | MT-860 | MT-1200 |

| 容量 | 1.5-2吨/小时 | 3吨/小时 |

| 尺寸 | 1150*860*1160mm | 2100*1700*1400毫米 |

| 脱粒率 | 98% | 98% |

| 车轮 | 四 | 六 |

| 重量 | 112公斤 | 200公斤 |

| 力量 | 汽油机 | 10-12HP柴油机 |

机动玉米脱粒机的优点

- 高工作效率: 处理能力达到 1.5–2吨/小时或最高3吨/小时, 适合连续作业。

- 全自动操作: 谷物进入机器后,脱粒和杂质去除自动完成,无需人工干预。

- 操作简便: 只需启动多功能脱粒机并喂入谷物,无需复杂调节。

- 节省时间和能源: 整个过程可以由 一名操作员效率远高于传统手工脱粒。

- 多用途应用: 一台机器即可完成脱粒 四种不同的谷物包括玉米、小米、高粱和大豆。

- 清洁成品输出: 该机器有效地将谷粒与杂质分离,确保成品清晰高质量。

多功能脱粒机常见问题解答

如何脱粒不同作物?

为了适应不同谷物,只需打开顶部盖子,根据粒径更换筛网。在脱玉米时,应拆除内部的四个轴,以更好地适应较大的谷粒,确保操作顺畅高效。

是否易于移动?

滚轮+推手,移动方便。

多功能脱粒机可以用于哪些作物?

玉米、小麦、大豆、高粱等

动力来源?

2.2-3kw电机、6-8Hp柴油机、170F汽油机。

产量、脱粒率?

1.5-2吨/小时;98%

工业高粱脱粒机出售给布基纳法索

上周,我们的销售经理通过阿里巴巴收到一份询价请求(RFQ),最初通过电子邮件与客户沟通,然后通过WhatsApp。客户需要一台汽油动力的多功能脱粒机、一台行走式拖拉机、一台玉米播种机和一台圆盘犁。在确认所有需求后,我们的销售员迅速提供了报价。

客户主要关心的是说明书是否有法语版本。虽然我们的手册通常是英文的,但我们提供了法语翻译,解决了这个问题。结果客户成功下单。以下是包装和发货照片。

结论

总之,这款多功能谷物脱粒机以其高效率、广泛的作物适应性和稳定的性能脱颖而出。它可以快速脱粒玉米、水稻和小麦等多种谷物,大大降低劳动和时间成本。

该机器支持汽油动力选项,适用于不同工作环境,操作简便,维护方便。此外,我们提供多语言说明书和根据客户需求定制的服务,确保安装和使用顺利。

如果您正在寻找可靠、实用且具有成本效益的多谷物脱粒解决方案,欢迎联系我们获取报价和详细咨询。