自动碾米厂出售给肯尼亚

Automatic rice mill plant is professional machinery and equipment that polishes brown rice into white rice. With the increasing demand for rice, polished, polished rice is one of the staple foods that people often eat in their daily lives. Our rice polishing machines are available in many different models. There are small rice milling machines and large rice polishing units.

其中,产量较高的大米抛光机组有不同的配置组合。他们有不同的输出和支持机器。客户可以根据自己的需要选择碾米机型号。

自动碾米厂订单详情

我们的客户来自肯尼亚。他通过搜索找到了我们的碾米机网站。然后他向我们发送了碾米机的询盘。我们的销售经理立即联系了客户。通过沟通,我们了解到客户想开办一个小型碾米厂。首先,我们向客户介绍了一台日产25吨的碾米机。客户说他想要一台容量更小的机器。所以我们推荐一台日产15吨的碾米机。客户表示满意。

随后我们向客户详细介绍了该机的工作视频、参数、结构。客户也说没问题。然后我们讨论了机器的立方体和运输问题。客户最终决定购买一台15吨碾米机。

碾米机规格

| 模型 | NNJ/AG-25 |

| 容量 | 1000公斤/小时 |

| 力量 | 30.65千瓦 |

| 精米率 | 71% |

| 尺寸 | 4800*3000*2900毫米 |

碾米机工作原理

糙米通过调节机构从进料斗进入研磨室。然后,螺旋头将糙米输送到砂辊上,并沿着砂辊表面呈螺旋状。砂辊以一定的线速度旋转,摩擦糙米皮层。并使米粒与米粒、米粒与米筛相互摩擦、碰撞,从而打开棕白色。同时,通过空气喷射的作用,将麸粉从米粒中挤出,从筛子中排出。

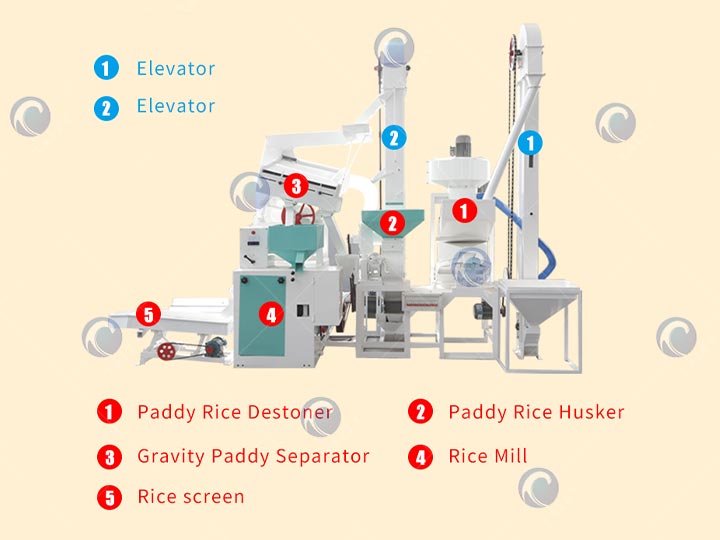

自动碾米厂的工作流程

- 首先,将稻谷放入提升机的进料斗中。

- 然后,稻谷进入去石机,去石机将稻谷中的石子去除。

- 接下来进入脱壳机,去除稻谷的外壳。

- 然后进入重力谷选机,未带壳的稻谷再次被送至脱壳机。剩下的糙米进入碾米机。

- 碾米机加工后的大米进入碎米分级筛,将完整的米与碎米分开。

组合碾米机组有哪些优点?

1、自动碾米设备从稻谷清理、去石、脱壳、粒糙分离、碾磨、白米分级等加工工序实现自动化、连续化。

2、全自动碾米机造型美观,结构紧凑,占地面积小,大米无处藏身。且具有出米率高、碎米少、电耗低的特点。

3、大米放入机器后,一步即可得到标准的成品米。

4、处理后的大米洁白洁净,光泽度高

5、自动碾米厂布局合理,操作方便,加工过程中无需徘徊操作。

全自动碾米机可以配备哪些机器?

客户采购的机械有清米机、去石机、砻谷机、重力选米机、碾米机、分级机等。

大米抛光机组还可以与其他相关机器组合,形成更完整的产品线。如带水的大米抛光机、色选机、包装机等。

联合碾米机包装发货图片