花生播种机 | 多功能花生种植机

| 模型 | 2BHMF-4 |

| 尺寸 | 2940×1200×1300毫米 |

| 重量 | 350公斤 |

| 生产率 | 0.8-1.6英亩/小时 |

| 播种量 | >98% |

| 行数 | 4行 |

花生播种机确保花生的高效与精准播种。该4排机械由拖拉机通过动力输出轴驱动,保证田间运行的同步性和可靠性。标准功能包括施肥、播种和覆土——满足花生种植的核心要求。

为适应现代农业生产和多样化的客户需求,我们的花生播种机可以升级为带有药箱用于喷药、地膜覆盖、压土轮和旋耕等附加功能。这些可定制选项使农户能够根据当地田间条件提高播种效率和作物防护。

该花生播种机的工作能力为0.5至3.2英亩/小时,非常适合小型和中型农场。其结构简单、操作方便、价格亲民,使其在国内外农户中广受欢迎。

出售花生播种机

我们的花生播种机可以一次播多排花生,例如2排、4排和6排。型号为2BH-2、2BH-4和2BH-6,可满足多排播种需求。

花生播种机功能强大,可一次性完成施肥、播种、喷药、覆盖、覆土、起垄等作业。另外,客户还可以根据自己的需要调整株距和行距。

整个作业过程中,该机操作方便,播种均匀,工作效率高,经久耐用。它是农民日常播种的常用工具。

此外,除了花生播种机,我们还提供花生收获机、花生摘果机、花生剥壳清选一体机等。这些机械在从种植花生到获得花生仁的过程中为人们节省大量人力和时间。

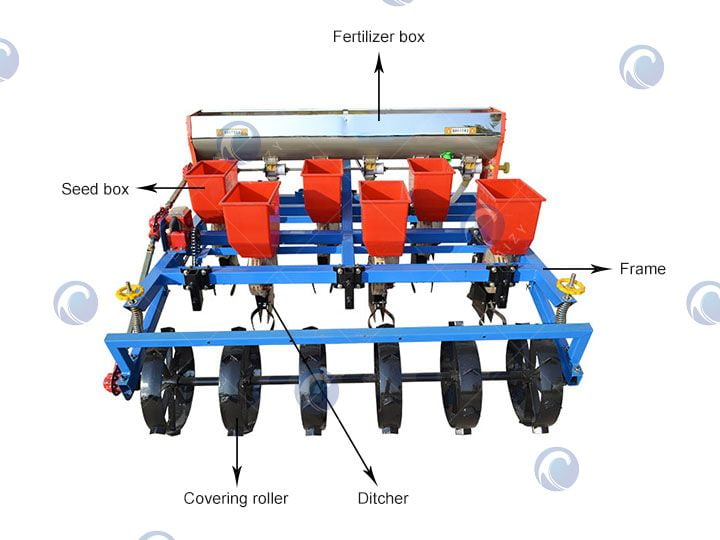

花生播种机结构

4排花生播种机主要由肥料箱、种子箱、开沟器和机架组成。为实现起垄、覆膜和喷洒等附加功能,可集成额外组件。

它确保深播、行距均匀且覆土良好,从而促进健康苗情生长。

多功能花生种植机技术参数

| 模型 | 2BHMF-2 | 2BHMF-4 | 2BHMF-6 |

| 匹配功率(hp) | 20-40 | 40-70 | 60-90 |

| 尺寸 | 2940×1200×1300毫米 | 2940×1600×1300毫米 | 2940×1900×1300毫米 |

| 重量 | 180公斤 | 350公斤 | 450公斤 |

| 种箱容量 | 10公斤*2 | 10公斤*4 | 10公斤*6 |

| 行数 | 2行 | 4行 | 6行 |

| 行间距 | 300-350毫米 | 300-350毫米 | 300-350毫米 |

| 种子空间 | 80-300毫米 | 80-300毫米 | 80-300毫米 |

| 生产率 | 0.5-0.8英亩/小时 | 0.8-1.6英亩/小时 | 1.6-3.2英亩/小时 |

| 播种量 | >98% | >98% | >98% |

多功能花生播种机如何使用?

- 首先检查花生播种机,确保所有部件运转正常。

- 当机器运转正常后,将肥料装入肥料箱,把种子装入种子箱。

- 启动施肥系统,使肥料通过施肥器流动并由施肥铲置入土壤。

- 开始播种,种子经计量后落入沟槽,同时机器同步开沟并覆土。

- 将除草剂桶连接到拖拉机的空气压缩系统,在一次作业中即可完成施药、播种、施肥、起垄和覆盖。

多功能花生播种机优势

- 4排花生播种机结构简单、质量轻,单人即可轻松操作。

- 适应各种地形,包括丘陵和山区,对土壤表面的影响小。

- 地膜宽度可调,支持单行和多行播种,覆膜压轮确保有效覆膜且损伤最小。

- 该机集播种、喷药和覆膜功能于一体,大幅提升整体种植效率。

- 行距可调,以满足不同的种植需求。

- 具有高精度的播种性能,节省种子,保证一致的播种深度并实现高出苗率。

销售至肯尼亚的花生播种机

上周有一位来自肯尼亚的客户通过阿里巴巴联系了我们。我们的销售经理通过WhatsApp与客户沟通。在了解客户需求后,我们向客户推荐了4行花生播种机。

后来客户得知我们的机器可以增加起脊和层压两个功能,要求增加这两个功能。

最后,客户决定下订单。发货前,我们为客户测试了4行花生播种机,并根据客户的要求发送了测试视频。以下是包裹运送图片。

为什么客户选择我们的四行花生播种机?

- 我们的花生播种机采用优质材料制造,符合国际耐用性和性能标准。

- 专业销售人员提供专家建议,帮助客户选择最合适的型号。

- 我们提供多种安全且灵活的支付方式以满足客户偏好。

- 客户在购买过程中会收到包含机器详细照片和视频的透明更新。

- 我们在线上和线下提供可靠的售后服务,确保设备平稳运行并提升客户满意度。

请随时联系我们!

凭借高效率、可靠性能和人性化设计,我们的花生摘果机是希望提高收获产能并降低人工成本的农户和加工商的理想选择。

凭借我们的专业团队、灵活的付款方式和全面的售后支持,您可以放心投资我们的机械。无论您是要扩展农场规模还是升级现有设备,我们都能提供满足您需求的定制化解决方案。

立即联系我们,获取免费报价和关于为您的业务选择合适花生摘果机的专业指导!

- 该机结构简单、重量轻、单人操作方便。

- 适用于丘陵、山地等各种地形,对沟地面破坏小。

- 薄膜宽度可调,可单行或多行播种。

- 该设备集播种、喷药、覆膜于一体,大大提高了花生播种效率。

- 花生播种机的播种行数和播种行距均可调节。

- 该机播种精度高,节省种子。而且播种质量高,播深标准一致。