玉米脱粒机 | 高产量玉米脱粒机

| 模型 | 5TY-80D(带提升送料机及输送机) |

| 力量 | 15HP柴油机或7.5KW电机 |

| 容量 | 6t/h(玉米种子) |

| 脱粒率 | ≥99.5% |

| 重量 | 350公斤 |

| 尺寸 | 3860*1360*2480 毫米 |

The Maize Sheller Machine is a high-efficiency corn threshing equipment that streamlines the post-harvest process for farmers and grain processors.

该机器每小时能够处理高达6吨的干玉米,确保超过99.5%的脱粒率和低于1.5%的损坏率。它将脱粒、分离、清洁和谷物卸载结合为一个流畅的操作。

该玉米脱粒机由柴油发动机或电动机驱动,配备输送喂料系统、旋风排料器和可调组件,以适应各种工作条件。

出售玉米脱粒机

Maize sheller machine for sale – designed to efficiently remove corn kernels from the cob in large quantities. This versatile machine supports both diesel engine and electric motor options, allowing it to meet the diverse power needs of customers in different regions.

为了进一步提高便利性,提供可选附件,如粮食输送管和输送带,这有助于在操作过程中显著减少人工劳动。

In addition to the dry corn sheller, we also offer a fresh corn threshing machine specially made for processing undried corn, providing more flexibility for different harvesting conditions.

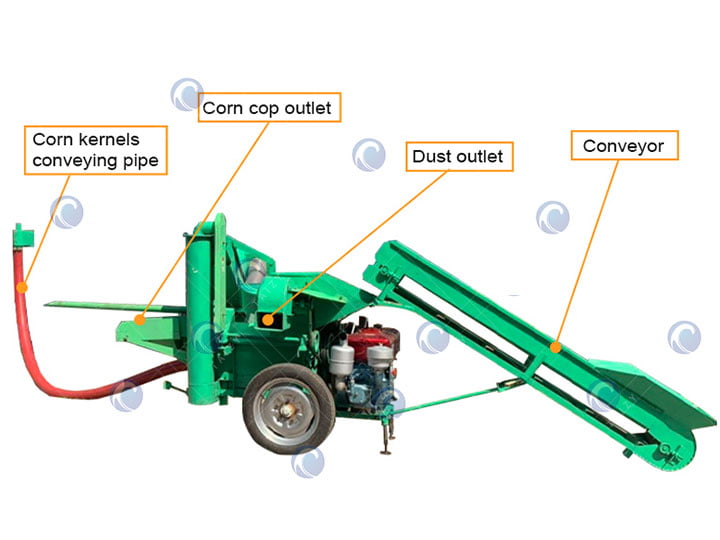

玉米脱粒机的结构

玉米脱粒机具有精心设计的结构,确保高效的玉米脱粒和简单的操作。它由耐用的部件构成,这些部件协同工作,将玉米粒从玉米棒中分离,同时尽量减少劳动强度。

- 玉米进料口 - 玉米被送入机器的地方。

- 内部脱粒和滚动装置 - 通过高速旋转和摩擦将玉米粒从穗轴上分离。

- 玉米粒出口 - 在处理后排出分离的玉米粒。

- 玉米穗出口 - 单独排出空穗轴,以保持过程的清洁和高效。

- 电力系统 - 配备电动机或柴油发动机,以适应不同的电力供应。

- 机器框架 - 提供稳定的基础,以支持操作期间的所有组件。

Optional equipment: To further improve working efficiency, the maize sheller machine can be equipped with a conveyor belt and a grain conveying pipe. The conveyor belt simplifies the feeding process by automatically delivering corn to the threshing chamber, reducing the need for manual handling.

与此同时,粮食输送管道允许将去壳的谷物集中收集并运输到指定地点。这两项改进有助于节省劳动力,使整体操作更加便捷和高效。

商用玉米脱粒机规格

| 模型 | 5TY-80D(带提升送料机及输送机) |

| 力量 | 15HP柴油机或7.5KW电机 |

| 容量 | 6t/h(玉米种子) |

| 脱粒率 | ≥99.5% |

| 损失率 | ≤2.0% |

| 破损率 | ≤1.5% |

| 杂质率 | ≤1.0% |

| 重量 | 350公斤 |

| 尺寸 | 3860*1360*2480 毫米 |

玉米脱壳机的工作流程

- 玉米喂入输送带

- 用户首先将玉米放在玉米脱粒机的输送带上。

- 输送带送入脱粒室

- 输送带持续移动,将玉米运送并送入机器的脱粒室。

- 脱粒室内的脱粒动作

- 一旦进入脱粒室,玉米就会遇到铁辊和筛网。

- 铁辊旋转,通过与筛网的相互作用,对玉米施加摩擦和冲击力。这一动作将玉米脱粒,使谷粒从穗子上松动。

- 玉米穗和玉米粒的分离

- 在脱粒后,机器内部的机制可能依赖于大小、形状和重量等差异,将玉米棒与玉米粒分开。

- 从相应的出口排出

- 分离出来的玉米粒通过指定的玉米粒出口排出机器。

- 玉米棒通过棒出口排出,完成脱粒过程。

全自动玉米脱粒机的优点

- 一步多功能 – 这台机器集脱粒、分离、清洗和堆叠于一体,在一次操作中完成所有任务。

- 高效率 – 每小时可输出高达6吨,极大提高了生产效率。

- 卓越的性能 – 它确保高玉米粒去除率,并提供干净的最终产品。

- 耐用的结构 – 采用高质量材料制造,机器坚固可靠,适合长期使用。

- 高效的粮食运输 可选的粮食输送管帮助将玉米颗粒直接输送到指定位置,减少劳动力并提高便利性。

工业玉米脱粒机的安装与调整

- 安装柴油发动机 在框架上。调整螺杆以收紧或放松皮带。拧松分离螺丝以抬起发动机,放松皮带,并允许无负载启动。

- 检查皮带张力 用于主轴、螺旋输送机、电梯和风扇。确保所有皮带适度紧绷。

- 调整振动筛角度 通过改变两个支撑框架的高度来控制杂质排放速度。

- 设置杂质出口在筛网下方系一个大编织袋,以收集排放的杂质。

- 稳定机器 通过调整柴油机下方的支撑杆,直到车轮几乎离地,以确保稳定运行。

立即联系我们!

Our maize sheller machine offers exceptional efficiency and durability. With options for diesel or electric power and additional accessories like conveyor belts and grain pipes, this machine can be customized to fit your specific needs and improve your corn processing workflow.

Besides the maize sheller, we provide a full range of corn processing equipment, including corn grinders and fresh corn threshers, designed to help you handle every step of corn production with ease.

如果您想提高生产力并降低劳动力成本,请随时与我们联系以获取详细咨询和有竞争力的价格。我们期待帮助您找到完美的机械解决方案!