4行插秧机用于水稻播种

| 模型 | 2ZS-4 |

| 尺寸 | 2140×1630×910(毫米) |

| 重量 | 165公斤 |

| 发动机功率 | 2.6/3000(千瓦/转/分) |

| 工作线 | 4行 |

| 工作速度 | 0.34-0.77(米/秒) |

| 线距 | 300(毫米) |

| 播种距离 | 210;180;160;140;120(毫米) |

| 播种深度 | 15-35(毫米) |

插秧机已经是大多数水稻种植户的首选。如今,为了更高效地进行农田工作,使用机械插秧已成为普遍现象。插秧机动力强劲。

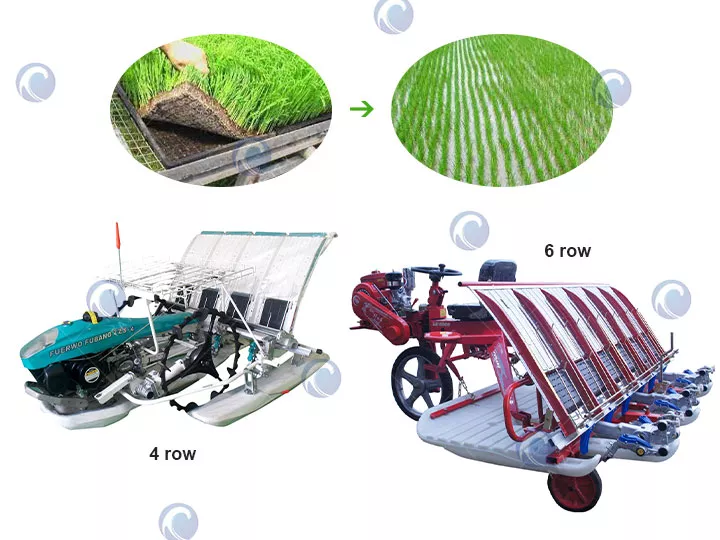

我们的插秧机一次可以种植 4 或 6 行秧苗。与手工劳动相比,效率更高,插秧效果也不错。

水稻插秧机简介

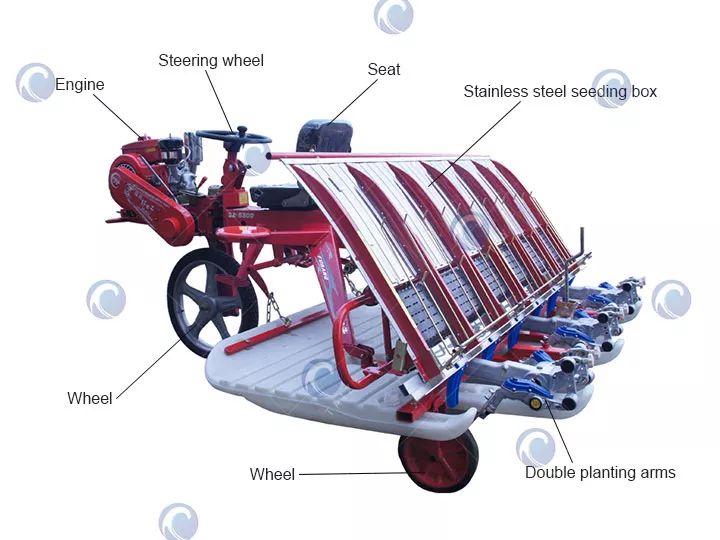

目前,我们生产 4 行和 6 行型号的水稻插秧机。对于四行插秧机,用户需要用手推动机器才能工作。水稻插秧机由汽油发动机提供动力。使用六行插秧机时,客户需要坐着驾驶插秧机。对于6行插秧机,动力为柴油机。

除此之外,我们可以将这款插秧机的深度从 15 厘米调整到 35 厘米。

除了这些水稻移栽机外,我们还生产蔬菜移栽机,可移栽各种蔬菜的秧苗。

什么样的机器可以与水稻播种机配合使用?

水稻移栽机可以与育苗机配合使用。我们可以先使用育苗机培养秧苗,然后在秧苗成熟时进行移栽。这样可以节省大量人工育秧和移栽的时间,提高工作效率。

为什么我们需要使用水稻播种机?

- 工作效率高。我们都知道,人工移植是非常耗时的。并且需要雇用很多人员,这样就提高了种植水稻的成本。因此,使用水稻播种机可以更加高效且更具成本效益。

- 水稻播种机运转良好。因为机器工作可以实现并保持标准的株距和行距。这也有助于幼苗更好地生长。

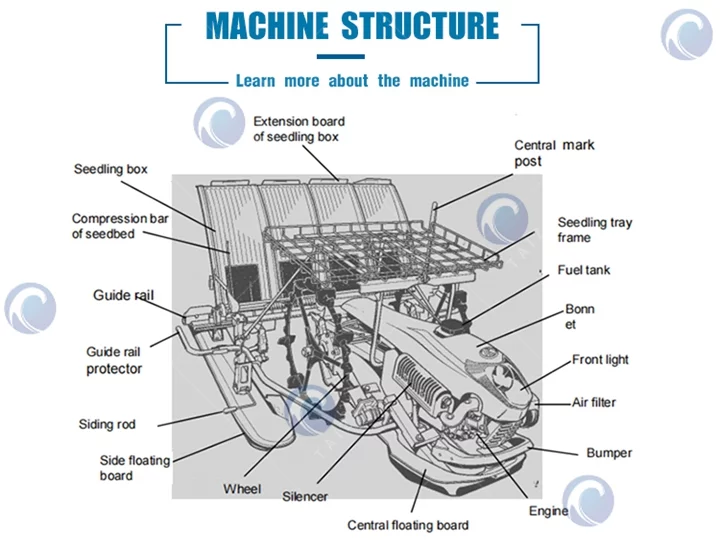

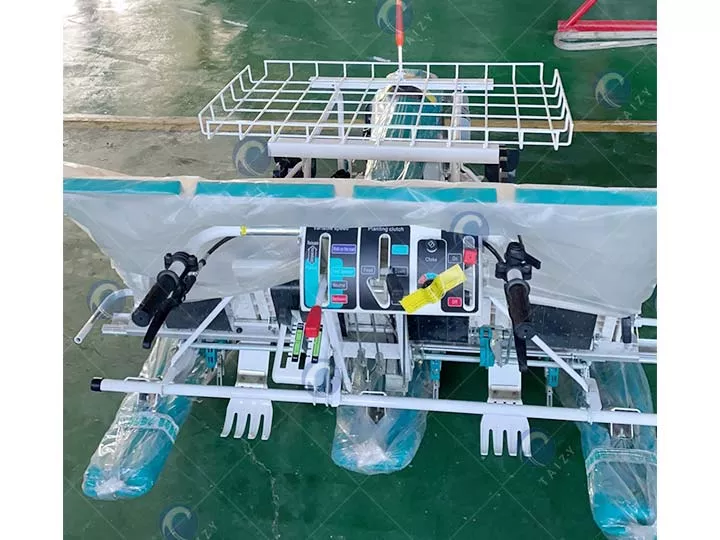

水稻插秧机的结构

- 第一个是4行水稻种植机。该型水稻插秧机主要由秧箱、秧盘架、发动机、车轮等组成。以下是该机的详细结构图。

2、下图为6行水稻插秧机结构图。

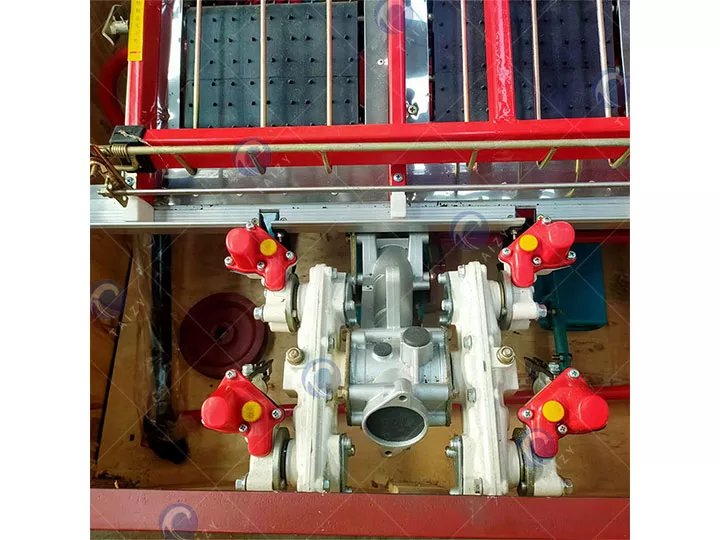

水稻插秧机工作原理

虽然机器的外观不同。但机器工作的基本流程是大致相同的。

- 将整张的秧苗放入育苗箱中。

- 然后随秧箱横向移动,取苗装置逐次分次取走一定数量的秧苗。

- 在轨迹控制机构的作用下,秧苗按照农艺要求插入土壤中。

- 最后,取苗装置按照一定的轨迹返回秧箱取苗。

水稻插秧机详细技术资料

4排

| 模型 | 2ZS-4 |

| 尺寸 | 2140×1630×910(毫米) |

| 重量 | 165公斤 |

| 发动机功率 | 2.6/3000(千瓦/转) |

| 工作线 | 4行 |

| 工作速度 | 0.34-0.77(米/秒) |

| 线距 | 300(毫米) |

| 播种距离 | 210;180;160;140;120(毫米) |

| 播种深度 | 15-35(毫米) |

6排

| 模型 | CY-6 |

| 柴油机型号 | 175F手启动 |

| 柴油机输出功率(kw/HP) | 3.72/5.5 |

| 柴油机转速(r/min) | 2600 |

| 移栽行数 | 6 |

| 行距(mm) | 300毫米 |

| 山间距离(mm) | 120/140毫米 |

| 移栽效率 | 0.35-0.5英亩/小时 |

| 净重 | 300公斤 |

水稻播种机有哪些特点?

- 插秧机作业速度快,播种秧均匀,有利于抗病高产!

- 4行插秧机需要手持,6行插秧机可以驾驶。人们无需弯腰插秧。这大大减轻了人们的劳动强度。

- 该机工作实现一苗一坑,避免了浪费苗的现象。

- 插秧机种植的水稻有利于水稻的通风和阳光。这样的米粒饱满,空壳率低。

泰智机械-客户的最佳选择

- 我们是一家专业的农业机械制造商。我们致力于研究和设计更方便、更优质的农业机械。

- 高品质机器。我们制造的机器由最好的材料制成。这样,机器的使用寿命就更长了。

- 专业的服务团队。我们的销售经理可以为您提供专业的解决方案,欢迎咨询我们。

- 一年售后服务。我们将为客户提供一年的线上或线下售后服务。