Automatic Nursery Seeding Machine Delivered to Austria for a Modern Greenhouse Nursery

In November 2025, we successfully exported an automatic nursery seeding machine to Austria and delivered it to an advanced greenhouse nursery to help them improve seedling efficiency and quality.

Customer background

The customer is a modern greenhouse nursery located in Tyrol, Austria. They mainly engage in vegetable and flower seedling cultivation, supplying local farms and gardening enthusiasts.

As their business expanded, they required higher seedling capacity and quality. Their goal was to reduce manual labor, improve germination consistency, and ensure a high seedling survival rate through automated equipment.

Customer requirements

During our communication, the customer highlighted several key needs:

- Ability to handle various types of seeds (such as tomatoes, peppers, leafy greens, etc.).

- Automatic completion of tray soil filling, hole punching, seeding, secondary covering, and watering.

- High seeding accuracy and strong seedling survival rate.

- Durable structure, easy maintenance, suitable for greenhouse environments.

Our solution

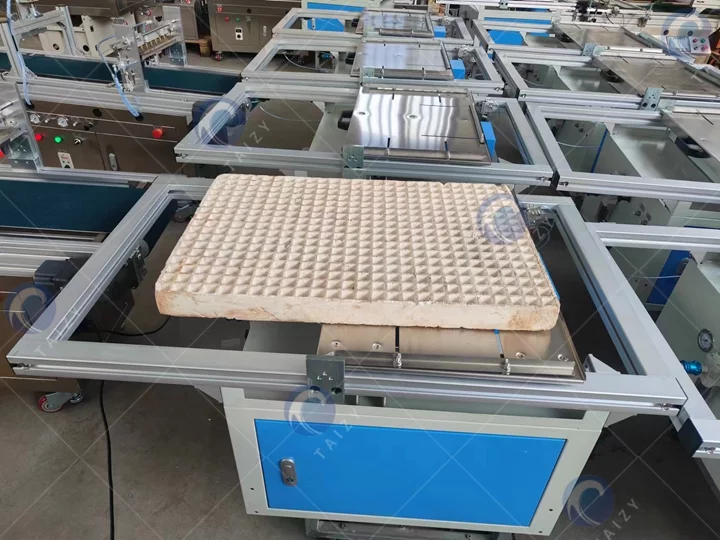

Based on their requirements, we recommended the KMR-78-2 automatic nursery seeding machine. Its main advantages include:

- High capacity: Capable of processing about 500–600 trays per hour.

- High seeding accuracy: Accuracy reaches 97–98%, improving seedling survival rates.

- Fully automatic process: Integrates soil filling, soil brushing, hole punching, seed suction, soil covering, and watering in one machine.

- Seed adaptability: Equipped with multiple nozzle sizes, handling seeds from 0.3 mm to 12 mm.

- Modular structure: Sensors, brushes, punching devices, and the electrical control cabinet work together to ensure efficiency and stability.

Implementation results

After the automatic nursery seeding machine arrived in Austria, it was put into operation shortly following installation, debugging, and operator training.

The customer reported highly stable seeding performance, uniform tray sowing quality, and a significant increase in germination rate.

The automated workflow greatly reduced labor input and helped save manpower costs.

During operation, the equipment demonstrated low failure rates, simple maintenance procedures, and operators quickly mastered daily upkeep.

Conclusion

Exporting our automatic nursery seeding machine to the Austrian nursery not only highlights the reliability of our equipment in modern European greenhouse cultivation but also showcases its strong value in improving seedling efficiency and reducing operational costs.

We look forward to cooperating with more nurseries in Europe and around the world to support their technological upgrades and production improvements.