Forage baler wrapper machine sold to Costa Rica

Many farmers now need a lot of straw and forage to feed their animals. And traw and forage are plentiful in spring and summer. But there will be less fresh forage in autumn and winter, so farmers need to store it in advance. But, manually collecting and baling forage is labor-intensive and time-consuming. So, it will be much more convenient to use the baler wrapping machine.

The customer needs to cut the straw and forage before baling. And, customers can use the chaff cutter to improve efficiency. And the combined work of chaff cutter machine and a baler wrapping machine are a good choice. This not only improves work efficiency but also improves the quality of silage.

How does the customer purchase forage baler wrapper machine?

This client of ours is from Costa Rica. He wants to buy two forage straw baler machines from us as prototypes to put in Costa Rica for customers to visit to understand the local market. And the customer needs two machine power is motor and diesel engine. Also, he needs plastic film and thread.

After fully understanding the customer’s needs, we recommend two TZ-55-52 models to the customer. In the process of communicating with customers, customers are more concerned about technical support, parts, film rolls, and ropes. And we have provided detailed answers to these questions. Finally, after that, the customer decided to buy both machines.

What is hay baler machine?

The corn stalk baler machine can bundle and wrap all kinds of pasture, straw, corn straw, wheat straw, sweet potato seedlings, peanut seedlings, soybean straw, and other dry and fresh grasses. And the coated straw has a high commercial value, turning the waste of crops into treasure and improving the utilization rate of resources. Also, it can reduce the cost of feeding, improve the yield and quality of meat or milk. And the machine has the characteristics of a dense and reliable coating, good stretching effect, flexible operation, and convenient use.

What is the specifications of small round baler?

| 2100*1500*1700mmModel | TZ-55-52 |

| Power | 5.5+1.1kw , 380V,50HZ,3 phase (motor); 18hp (diesel engine) |

| Bale size | Φ550*520mm |

| Baling speed | 50-60 pcs/h, 5-6t/h |

| Machine size | 2100*1500*1700mm |

| Machine weight | 750kg |

| Bale density | 450-500kg/m³ |

| Film wrapping speed | 13s for 2 layer film,19s for 3 layer film |

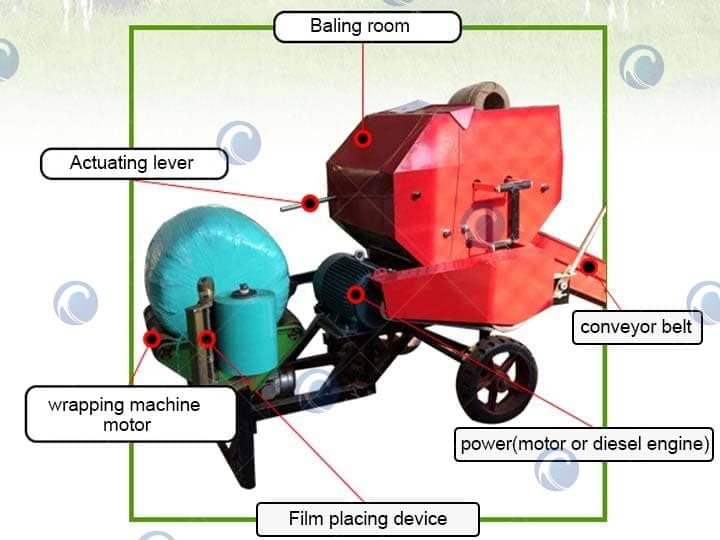

Structure of the round forage packing machine

The round straw packing machine generally includes conveyor, baling room, motor or diesel engine, actuating lever, wrapping machine motor, film placing device, etc. The machine is flexible and convenient to operate, with good quality and long service life.

How dose the hay baler work?

What is the workflow of the forage baler wrapper?

1. Firstly, start the machine. Then place the crushed straw forage on the conveyor belt.

2. Secondly, the machine will send the forage into the baling room. And in the baling room, the machine will use rope to tie the forage and straw.

3. And next the bundled hay will go to the wrapping device. The forage baler machine will wrap the bales of forage.

4. After wrapping the film, the machine will cut the film. Finally, the packaging is complete.

Precautions for silage baling and wrapping machine

1. The operator can use the baling and wrapping machine only after he has been strictly trained and qualified.

2. And round bale wrapper can use hemp rope and plastic net.

3. Also, when the moisture content of straw and pasture is more than 65%, it is not allowed to use this machine.

4. What’s more the operator is not allowed to pour liquids such as bacteria water onto the bale wrapper while bundling.

5. No 2 boring cars per hour are allowed.

Packaging and shipping of automatic forage baler wrapper

Before the machine is shipped, we will carefully check the machine and its equipped parts. And confirm the specific details with the customer. So, customers can rest assured to receive the goods. Also, in order to better protect the machine from damage and moisture. We will wrap the machine with plastic film first, and then use a wooden box with an iron frame to pack the machine. And the following are the packaging and delivery pictures of the baling and wrapping machine.