15TPD combined automatic rice milling machine

| Model | MNMS15B |

| Capacity(t/h) | 0.8-1.25 |

| Power(kw) | 18.5-22 |

| Size(L*W*H) | 1090*580*1420mm |

The 15TPD combined automatic rice milling machine is an efficient and compact production line designed for small to medium-scale rice processing. This unit integrates essential rice milling functions such as paddy cleaning, de-stoning, hulling, separating, milling, and grading into one complete system.

With a processing capacity of 15 tons per day, it ensures high output with minimal labor involvement. Ideal for rural rice mills, agricultural cooperatives, and small processing plants.

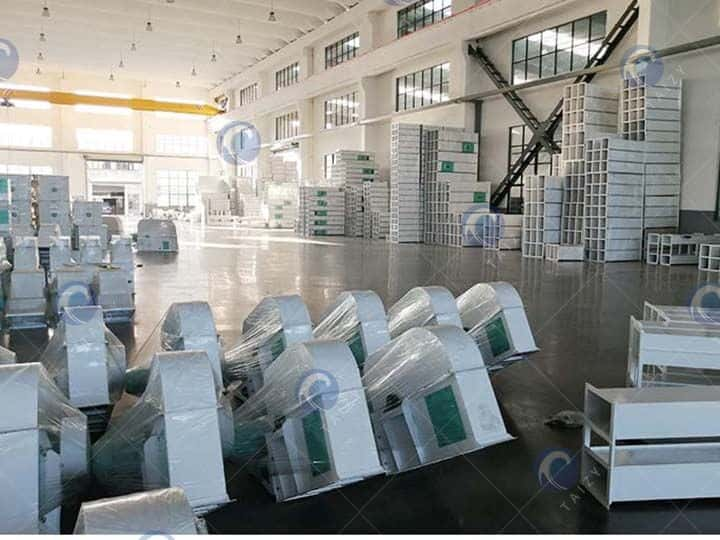

15TPD automatic rice milling machine for sale

Automatic rice milling machines efficiently convert brown rice into white rice, especially suitable for long-grain varieties thanks to their emery rollers. Our models—MNMS15B, MNMS18, and MNMS25—offer different hourly capacities to meet various production needs.

Compact and efficient, they ensure low breakage rates and effective bran separation. When used in a combined rice milling line, multiple machines can be configured for higher output and better milling performance based on your specific requirements.

Rice milling machine structure

The automatic rice milling machine includes a hopper, emery roller, sieve, handle, weights, air clearer, outlet, etc.

The function of each part of the rice milling machine units

- Hopper. The brown rice is loaded into the machine through this inlet.

- Emery roller and sieve. The rice is milled as it rubs between the emery roller and the screen, and the bran falls off through the sieve.

- Handle. Used to control the dropping amount of brown rice into the milling chamber.

- Weights. Adjust the milling pressure to control the degree of rice milling.

- Air clearer. Blows out the separated rice bran from the machine.

- Outlet. The processed white rice is discharged through this exit.

How does the rice miller machine work?

- Feeding hopper. Brown rice is introduced into the machine through the feeding hopper.

- Screw head. Guides the rice into the whitening chamber and directs it to the emery roller.

- Emery roller. As the rice spirals along the rotating roller, the abrasive surface grinds off the husk layer.

- Blower. Operates simultaneously to assist in separating bran powder from the rice.

- Sieve. Allows the bran to be expelled from the chamber, leaving behind clean, white rice.

Parameters of the rice mill machine

| Model | Capacity(t/h) | Power(kw) | Size(L*W*H) |

| MNMS15B | 0.8-1.25 | 18.5-22 | 1090*580*1420mm |

| MNMS18 | 2-3 | 22-30 | 1245*650*1660mm |

| MNMS25 | 3.5-4.5 | 37-45 | 1350*750*1800mm |

The features of rice milling machine for sale

- The machine produces high-quality milled rice with clean separation of rice bran.

- The finished rice is white, glossy, low in temperature, and has a low broken rate, making it suitable for long-term storage.

- It features a compact design, high efficiency, and simple operation.

- The powerful airflow system delivers double the air volume of traditional models, resulting in lower rice temperature and higher milling efficiency.

- Equipped with a rear-mounted motor and belt tensioning device, it is easy to adjust and maintain.

- Compatible with emery rollers, iron rollers, or a combination of both, it supports multi-stage whitening with higher output, lower energy consumption, and improved efficiency.

Feel free to contact us!

In conclusion, our automatic rice milling machines offer unmatched efficiency and precision in rice processing. With our commitment to quality and innovation, we ensure that every unit delivers optimal performance and reliability. Additionally, we offer a range of rice mill models catering to different production capacities.

Whether you require a smaller capacity unit or a larger-scale rice milling solution, we have the expertise and technology to meet your needs. Contact us today to learn more and request a quote.