Groundnut sheller machine | Peanut shelling machine

| Model | TBH-200 |

| Capacity | 200kg/h |

| Power | 2.2kW motor, 170F gasoline engine, 6hp diesel engine |

| Weight | 40kg |

| Size | 650*560*1000mm |

Groundnut Shelling Machine efficiently removes peanut skins, ensuring intact kernels with minimal breakage. Operating at capacities from 200 to 800 kg per hour, it offers versatile power options and high shelling rates.

Peanuts are highly sought-after for their nutritional value and various uses in products like peanut butter and oil. The growing demand necessitates efficient shelling methods, making groundnut sheller machines the preferred choice due to their labor-saving benefits.

Our CE-certified peanut shelling machine is renowned for its reliability and performance across regions such as Senegal, Nigeria, Kenya, Congo, Zimbabwe, Gambia, and Greece, meeting diverse agricultural and industrial needs effectively.

Best groundnut sheller machine

We have various models of peanut sheller machines. This article mainly introduces several small models of peanut shellers. They are TBH200, TBH400, TBH800, 6BHD-800D. They are mainly different in output. Customers can choose the machine that suits their needs.

In addition to these smaller peanut shellers, we also have larger peanut shelling units, which can shell peanuts in larger quantities.

Our groundnut sheller machine is designed to deliver outstanding performance and efficiency. Let’s dive into the specific models we offer.

Type 1: TBH200 peanut shelling machine

This model of peanut sheller can produce 200kg/h. The machine can work through an electric motor, gasoline engine, or diesel engine. Customers can choose the power they need.

We will equip the machine with two screens, customers have to change different screens according to the size of the peanut seeds.

Type 2: TBH400 industrial peanut shelling machine

This groundnut sheller machine is capable of shelling 300-400 kg of peanuts per hour. The power of the machine is the same as Type 1. Two different sizes of screens are available, customers can choose the right one to install and use.

Type 3: TBH800 groundnut shell removing machine

This groundnut sheller machine features a duct with a white color and includes a fan mechanism designed for a dual-stage shelling process. If peanuts are not fully cleaned during the initial shelling, they undergo a second shelling process. The machine is equipped with two screens, a larger one and a smaller one, both of which must be used simultaneously.

When peanuts are fed into the machine, they first pass through the larger screen to remove the fully shelled peanuts, while the peeled peanut pieces are discharged through an outlet. Peanuts that are less full or not cleanly peeled proceed through the fan mechanism to the second, smaller screen for further shelling.

Furthermore, the machine operates on diesel, electric, and gasoline engines, providing flexibility in power sources to suit different operational needs.

Type 4: 6BHD-800D groundnut sheller

This model of groundnut sheller is exactly the same as Type 3. However, this type of machine can be equipped with a rack and large tires. African customers like this type of peanut sheller.

Next, let’s take a closer look at the structure of our shelling machines.

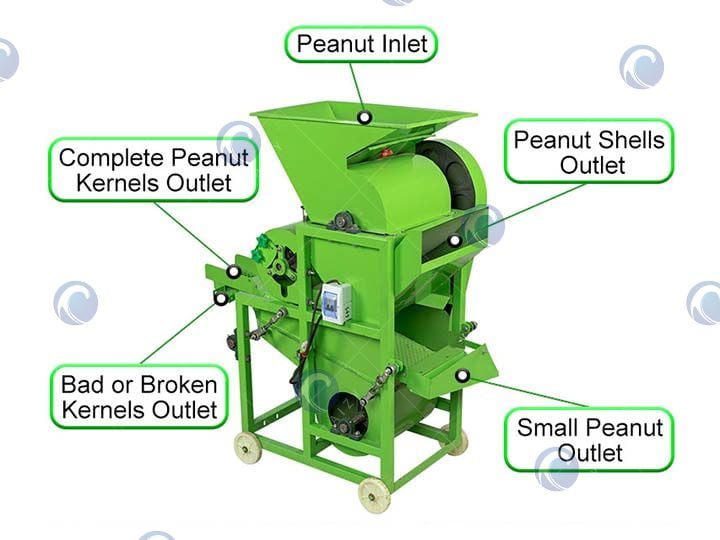

Structure of the groundnut shell removing machine

The main structure of these three models of groundnut sheller machines is similar. Below is the structure and details of the 400 model. The machine mainly includes an inlet, outlet, shelling chamber, etc.

Understanding the structure helps in appreciating the design and functionality of our machines. Next, we’ll delve into how these machines operate.

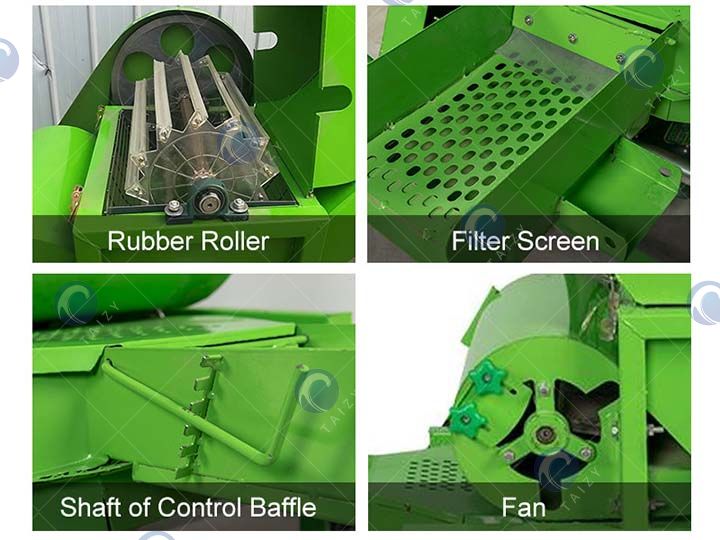

Working principle of groundnut sheller machine

Once in operation, the groundnut sheller machine consistently and evenly feeds peanuts into its hopper. Inside, the peanuts are subjected to repeated impacts, friction, and collisions from the rotor, effectively crushing them.

Following this process, the crushed peanut kernels and fragmented shells are separated through screens with precise apertures under the influence of rotating wind pressure. The lighter peanut shells are expelled from the machine, while the screened peanut kernels exit through another outlet, facilitated by a vibrating screen.

This section explains the mechanical process of deshelling, highlighting the efficiency of our machines. Now, let’s review the key parameters.

Parameters of groundnut shelling machine

| Model | Capacity | Power | Weight | Size |

| TBH-200 | 200kg/h | 2.2kW motor, 170F gasoline engine, 6hp diesel engine | 40kg | 650*560*1000mm |

| TBH-400 | 300-400kg/h | 3kW motor, 170F gasoline engine, 8hp diesel engine | / | / |

| TBH-800 | 600-800kg/h | 3kW motor, 170F gasoline engine, 8hp diesel engine | 160kg | 1330*750*1570mm |

| 6BHD-800B | 600-800kg/h | 2.2-3.0kW motor | 160kg | 1330*750*1570mm |

The parameters provide a detailed technical overview of each model’s capabilities. Moving forward, let’s highlight the advantages of using our shell removers.

The advantages of peanut shell remover

- High Productivity. The machine ensures clean shelling with an impressive output range of 200-800 kg/h. Customers can select the model that best fits their needs.

- Low Loss Rate. Designed to minimize kernel loss, the machine maintains a low loss rate, ensuring maximum yield.

- Minimal Crushing. The sheller has a small crushing rate, preserving the integrity of the peanut kernels.

- Simple and Reliable Structure. Its structure is straightforward, reliable, and easy to adjust, making it user-friendly and efficient.

- Versatile Operation. Suitable for both dry and wet peanuts, providing flexibility in use. However, overly dry peanuts may result in a higher crushing rate, while overly wet peanuts can affect efficiency.

Knowing the advantages helps in making an informed decision about our products. Let’s now look at a successful case study to illustrate this.

Automatic peanut sheller sold to the United States

The customer is a peanut butter worker in the United States. He contacted us by browsing our peanut shelling machine page. Our sales manager immediately contacted the customer. Through communication, we learned that the customer had previously purchased peanut kernels directly to process into peanut butter.

Recently, customers have wanted to shell peanuts themselves. According to the customer’s output requirements, we recommended the TBH400 model groundnut sheller machine. Since the machine was within the customer’s budget, the customer placed an order for a peanut sheller immediately after all the information was confirmed. Here is the packing and shipping picture of the machine.

Contact us!

Now that you know the numerous advantages of our groundnut sheller machine—from high productivity and low loss rates to minimal crushing, simple and reliable structure, and versatile operation—our machine is undoubtedly the best choice to meet your needs.

Whether your farm is large or small, we have the right model to help you increase efficiency and yield. Don’t hesitate any longer; contact us today for more information and a quote, and let’s embark on a journey toward efficient shelling together!