Automatic nursery seedling machine丨vegetable nursery seeder

An automatic nursery seedling machine is equipment that can sow the seed in the tray. And this nursery seedling machine can complete soil covering, punching, sowing, secondary covering, and watering at one time. Nursery planting machine has the features of time and energy saving, high survival rate, and seedling quality. So, this vegetable nursery seeder is a hot sale in North America, the Middle East, Southeast Asia, and Africa. For example Canada, USA, Australia, Kenya, Brazil, Thailand, Philippines, Morocco, Nigeria, Botswana, etc. And they are satisfied with our machine’s quality and service. Every time we will equip each machine with a full range of wearing parts and nozzles suitable for the customer’s seed size. In order to prolong the service time of the machine and ensure that the machine can be suitable for various seeds.

What is automatic nursery seedling machine?

An automatic nursery seedling machine can nursery all kinds of seeds, such as the seeds of fruits, vegetables, and flowers. We have 3 models of nursery seeder. And this passage is about the KMR-78-2, which is an automatic greenhouse seeder machine. For use in this machine, just put the tray on the machine, and the seedling machine will automatically complete a series of actions. It doesn’t take a lot of effort. And its capacity is 500-600 trays per hour. What’s more this vegetable nursery seeder’s seeding accuracy can reach 97-98%. High seeding precision can enable high survival rates.

To accommodate a variety of seeds, we produce nozzles of different sizes. So we will recommend the appropriate nozzles to customers. Also, we have the sprinkler section. You can choose this function according to your need. We also produce transplanter machines for these plug seedlings, which is further convenient for people to plant.

What seeds can the seeding machine nursery?

The automatic nursery seedling machine can nursery tomato, lettuce, Chinese cabbage, okra, cucumber, aubergine, watermelon, chili, sweet corn, petunia flower, rose, hemp, pumpkin, rapeseed, onion, etc. Therefore, this seeding machine has wide application.

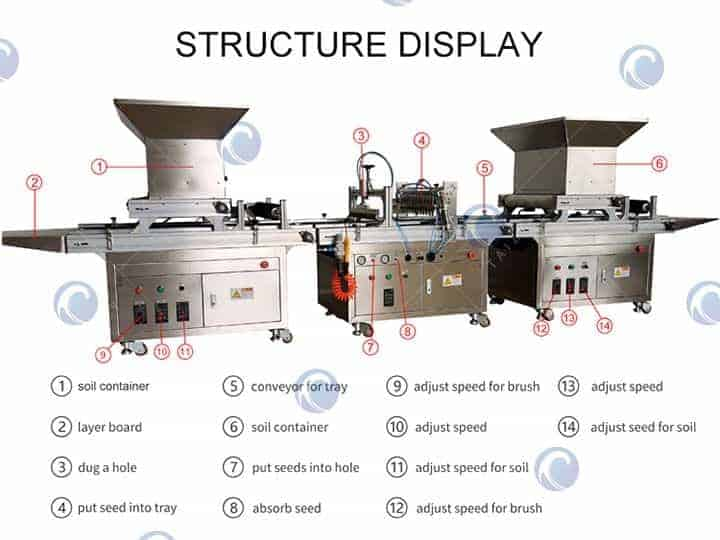

What are the components of vegetable nursery seeder?

This automatic nursery seedling machine mainly has layer board, soil container, hole punch, seeder, brush, sprinkler, electric control cabinet, etc. Also, there are several sensors, which help the machine can complete work with high accuracy. One nursery seeder can do all the procedures required for raising seedlings.

Working flow of the tomatoes nursery seedling machine

- First, start the machine and then put the base soil into the soil container.

- Second, the nursery seedling machine will puts the soil into the tray. And then the brush will remove excess soil.

- Third, the hole puncher punch neat holes.

- Next, the nozzle will suck the seed and then drop into the soil hole in the tray.

- Finally, the back soil container will puts the soil for covering the seed.

- If the tomatoes nursery seedling machine has a sprinkler, it will moisten the soil and seeds at the end.

How dose seedling tray machine work?

Specifications of the nursery seedling machine

| Model | KMR-78-2 |

| Precision | >97-98% |

| Principle | Electrical and air compressor |

| Size | 4800*800*1600mm |

| Weight | 400kg |

| Voltage | 220V /110V 600w |

| Size for seed | 0.3-12mm |

| Width of tray | <=540mm |

Below are the characteristics of nursery tray machine

- Automatic nursery seedling machine saves time and effort. Because mechanized production efficiency is high. Also, the nursery seedling machine can complete sowing and seedling at the same time.

- The automatic seedling raising machine sows dry seed directly, one seed at a time, and concentrated seedlings are raised. So the amount of seedlings per unit area is higher than that of conventional seedlings, which can reduce the floor space.

- Using this automatic nursery seedling machine, the seeds have strong stress resistance. And seeds are easy to transplant and have a high survival rate.

- The use of plug trays is suitable for long-distance transportation and mechanized transplanting. So, it broadens the development prospects of the vegetable market.

- The seeds cultivated by this seedling nursery are relatively scattered, which can both reduces the spread of pests and diseases and reduces the nutrient competition among the seedlings. At the same time, it can fully develop the root system and improve the quality of seedlings.