Plant transplanter machine | Self-propelled vegetable transplanter

| Model | 2ZBLZ-4 |

| Structure type | crawler self-propelled |

| Machine weight | 970kg |

| Supporting power | 4.05kw |

| Number of working rows | 4 rows |

| Working speed | 0.8-1.5 km/h |

Plant transplanter machines can transplant various vegetable seedlings, such as onions, tomatoes, and lettuce with precision and efficiency. So, using the transplanter can help farmers save much time and energy.

We offer three models: self-propelled, crawler type, and tractor-driven. Our transplanters are capable of transplanting from a minimum of two rows to a maximum of twelve rows simultaneously. Furthermore, we can customize rows and plant spacing to better accommodate the specific needs of our customers.

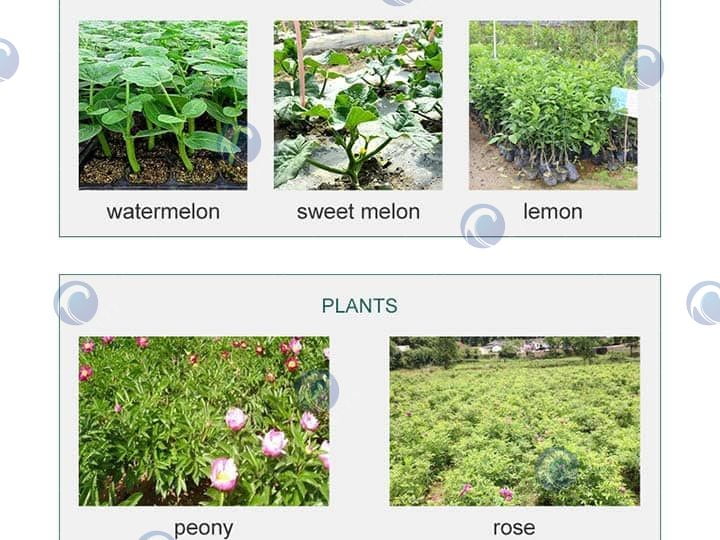

What seeds can the seedling transplanter transplant?

Plant transplanting machine can transplant a variety of plants including tomatoes, peppers, celery, onions, baby vegetables, broccoli, cabbage, carrots, coriander, hemp, tobacco, pumpkin, green beans, and fenugreek, among others.

Seedling transplanter machines are versatile and can accommodate various types of seedlings. Based on the specific needs of our customers, we recommend suitable machines tailored to their specific crop requirements.

Now that we understand what seeds can be transplanted, let’s explore the different types of vegetable transplanter machines available for sale.

Vegetable planting machine for sale

Our vegetable planting machines are designed to meet the needs of both small-scale plots and large-scale farms, delivering high planting accuracy and greatly improving efficiency and crop quality. We offer a variety of models including self-propelled, crawler-type, and tractor-trailed transplanters to suit different terrains and planting conditions.

The self-propelled and crawler-type machines are generally powered by gasoline engines, while trailed models operate in conjunction with tractors. Most models—except the basic self-propelled wheeled type—can be equipped with additional functions such as rotary tillage, fertilization, watering, mulching, ridging, transplanting, and even laying drip irrigation tape. This makes them highly versatile and capable of completing multiple tasks in a single pass.

Whether you’re working on flat farmland or ridge fields, these automatic seedling transplanters provide a flexible and efficient solution. Ready to find the right model for your crops? Explore our full range of vegetable planting machines today!

Type one: self-propelled vegetable transplanter

The self-propelled wheeled vegetable transplanter is a compact and lightweight machine designed for efficient and convenient seedling transplanting. Powered by a gasoline engine, it is capable of transplanting either 2 or 4 rows simultaneously, making it ideal for small to medium-scale vegetable farming.

To accommodate different crop requirements, both the row spacing and plant spacing can be customized and adjusted within a certain range. Compared to other types of transplanters, this model features a smaller footprint, making it easier to maneuver in tight field conditions.

With its user-friendly design and stable performance, this self-propelled vegetable transplanter is an excellent choice for enhancing planting efficiency. Next, let’s take a closer look at its structure and key components.

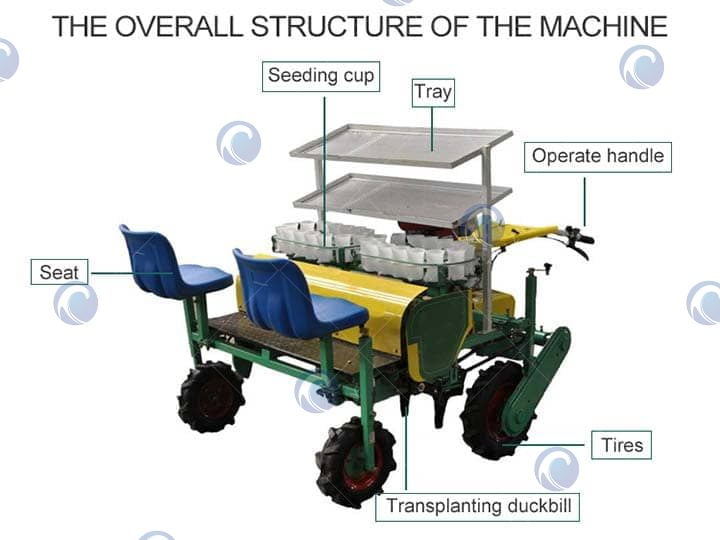

Structure of the self-propelled transplanter

The self-propelled transplanter is composed of key components such as a seedling cup system, operator seat, seedling tray holder, sturdy frame, transplanting mechanism, and wheels. Powered by a gasoline engine, the machine moves forward automatically.

During operation, workers sit on the seats and manually place seedlings from the tray into the seedling cups. These cups are then guided by the transplanting mechanism to insert the seedlings precisely into the soil, ensuring efficient and accurate planting.

How does the transplanter machine work?

What is the technical parameter of the plant transplanter machine?

| Model | 2ZBZ-2 | 2ZBZ-4 |

| Plant spacing | 200-500mm | 200-500mm |

| Row spacing | 300-500mm | 150-300mm |

| Capacity | 1000-1400m²/h | 1400-2000m²/h |

| Row | 2 rows | 4 rows |

| Power | 4.05kw | 4.05kw |

Next, let’s explore the crawler type transplanter, known for its stability and efficiency.

Type two: crawler type plant transplanter machine

The crawler-type plant transplanter is a versatile machine capable of transplanting 2, 4, 6, 8, 10, or even 12 rows in a single operation, making it ideal for large-scale planting.

In addition to transplanting, this machine can be equipped with optional functions such as mulching and drip irrigation tape laying, allowing farmers to perform multiple tasks simultaneously.

We also offer customization services to meet specific row spacing, function, and crop requirements, ensuring the machine fits each customer’s planting needs perfectly.

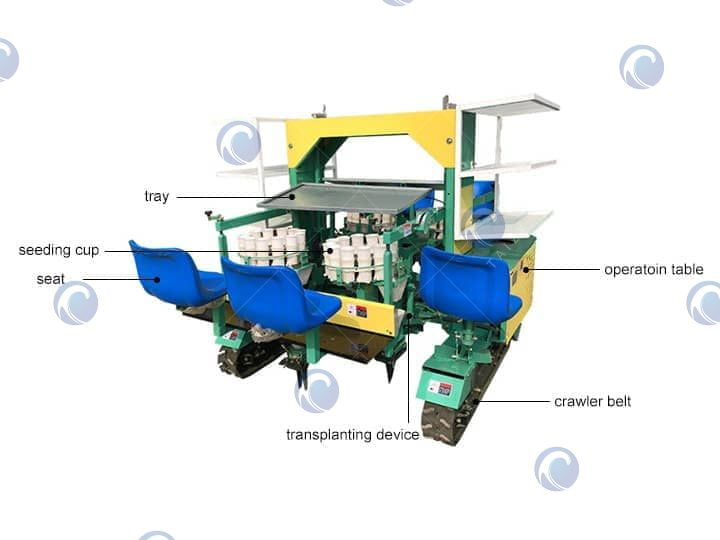

Structure of automatic onion transplanter

Compared to the first type, this automatic onion transplanter features a more advanced and complex structure. It is equipped with essential components such as a sturdy frame, operator seat, seedling cups, seedling tray holder, transplanting mechanism, crawler tracks, and an integrated operating system.

Additionally, it can be fitted with optional systems for mulching and laying drip irrigation tape, allowing multiple tasks to be completed in one pass—saving both time and labor during the planting process.

Working video of the automatic seedling planting machine

What are the specific parameters of the plant transplanter machine?

| Model | 2ZBLZ-4 |

| Structure type | crawler self-propelled |

| Machine weight | 970kg |

| Supporting power | 4.05kw |

| Transmission mode | belt drive |

| Number of working rows | 4 rows |

| Working speed | 0.8-1.5km/h |

| Plant spacing adjustment range | 200-450mm |

| Depth adjustment range | 60-120mm |

Differences between Type one and Type two

- Type One plant transplanter machine uses only a gasoline engine, while Type Two supports both gasoline and diesel engines.

- Type One plant transplanter machine is controlled by a hand-held system, whereas Type Two is operated via a side-mounted control panel.

- Type Two plant transplanter machine offers wider row spacing and plant spacing compared to Type One.

- Type One plant transplanter machine cannot support additional functions, but Type Two can include mulching and drip irrigation belt burying functions.

Type three: tractor-driven vegetable transplanter

The tractor-driven vegetable transplanter uses PTO for transmission. What’s more, it offers multiple additional functions, including fertilization, ridging, rotary tillage, watering, mulching, transplanting, and laying drip irrigation tape.

These features make it highly adaptable to meet diverse agricultural needs. We recommend the most suitable plant transplanter machine combination based on our customers’ specific requirements to ensure optimal performance and efficiency.

For larger operations, our tractor-driven vegetable transplanter is the ideal choice. Learn more about it below. We’ll start with its main components.

What are the main components of tractor-driven plant transplanter machine?

This type of automatic seedling planting machine has a seedling cup, seat, tray, frame, and transplant device. On the basic structure of the machine, we can add additional functions according to customers’ needs.

What are the specifications of the vegetable plant transplanter?

| Model | 2ZBX-2 | 2ZBX-3 | 2ZBX-4 | 2ZBX-6 | 2ZBX-8 | 2ZBX-10 | 2ZBX-12 |

| Planting spacing | 200-500mm | 200-500mm | 200-500mm | 100-400mm | 100-400mm | 100-400mm | 100-400mm |

| Row spacing | 250-500mm | 250-300mm | 250-300mm | 150-300mm | 150-300mm | 150-300mm | 150-300mm |

| Capacity | 1000-1700m²/h | 1000-2000m²/h | 1000-2700m²/h | 1400-3400m²/h | 2000-4000m²/h | 2700-5400m²/h | 3700-6700m²/h |

| Row | 2 rows | 4 rows | 4 rows | 6 rows | 8 rows | 10 rows | 12 rows |

| Power | >=30hp | >=30hp | >=50hp | >=60hp | >=60hp | >=60hp | >=60hp |

Check out the detailed specifications of our tractor-driven vegetable transplanter. Understanding these specifications highlights the advantages of our transplanter machines.

What are the advantages of a tractor vegetable seedling transplanter?

- The machine offers reliable performance and is easy to adjust due to its precise transmission ratio.

- It ensures accurate transplanting spacing, improving planting consistency.

- All key components are made from high-strength materials, providing long service life and stable operation.

- It greatly reduces labor intensity and helps save on labor costs.

- The transplanting quality is significantly improved, lowering overall production expenses.

- Uniform seedling growth allows for easier and more efficient field management.

- It increases crop yield and quality, delivering better economic returns.

- The machine saves both time and labor, achieving high operational efficiency.

Invest in our vegetable seedling transplanter

Our vegetable seedling transplanter offers versatile functionality and high efficiency to meet diverse agricultural needs. If you’re interested in our products, please feel free to contact us for more information or to request a quote.

Additionally, we recommend using our nursery seedling machine in conjunction with the vegetable seedling transplanter. This combination allows for efficient seedling cultivation before transplanting, ensuring a seamless process from nursery to field. We look forward to your inquiries and the opportunity to work with you!