Pumpkin seed extractor | Watermelon seed harvesting machine

| Model | 5TZ-500 |

| Size | 2000*1750*1450mm |

| Weight | 400kg |

| Working speed | 4-6km/h |

| Capacity | ≥500kg/h wet pumpkin seeds |

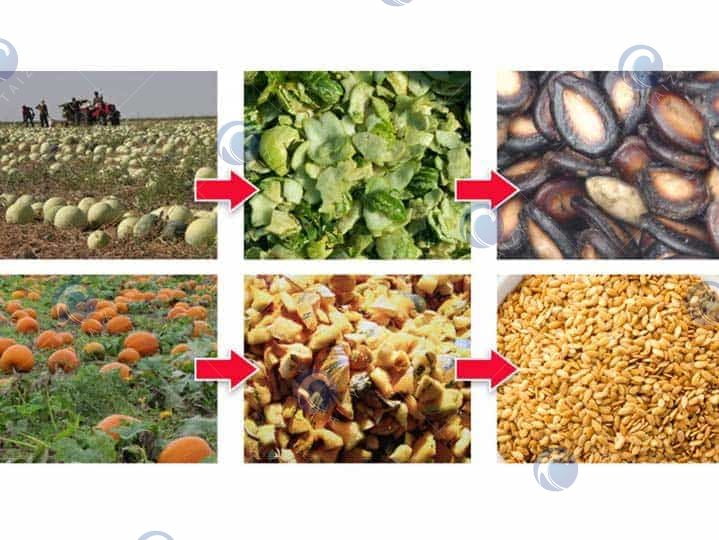

Pumpkin Seed Extractor Machine can efficiently process a variety of materials, including pumpkin, watermelon, and squash. This machine ensures a high integrity rate for extracted seeds while delivering clean results.

Equipped with durable wheels, it easily attaches to a tractor, allowing for seamless movement across fields and significantly reducing the need for manual labor.

Additionally, you can pair this extractor with our vegetable seed planter to enhance your planting process.

Application of watermelon seed harvester

Besides the watermelon seed, our machine can also process pumpkin, squash, melon, etc. Normally, the seeds of these crops can be used in skincare, medicine, health care products, and other fields, which have great value.

Pumpkin seed extractor for sale

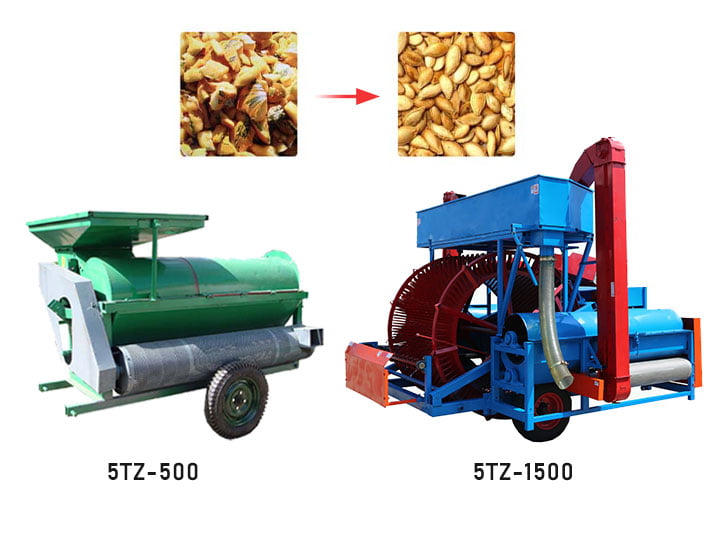

The pumpkin seed extractor machine is user-friendly and requires minimal training to operate. We offer two models: the 5TZ-500 and 5TZ-1500.

- The 5TZ-500 can be powered by diesel engines, electric motors, or tractors, while the 5TZ-1500 is designed for tractor use only. Both models feature wheels for easy mobility around the field.

Each machine can process various crops, and we provide screens with different mesh sizes to accommodate your specific needs. Depending on your crop type, we will recommend the most suitable screen.

Additionally, the two models have different output capacities, allowing customers to select the machine that best fits their requirements.

Type 1: 5TZ-500 pumpkin seed extractor

The 5TZ-500 pumpkin seed extractor is a compact and highly efficient machine designed for seamless pumpkin seed removal. This versatile extractor is capable of performing multiple operations simultaneously, making it an ideal choice for seed processing.

Key features

- Multi-functional operations. Performs crushing, squeezing, separating, and cleaning in one go.

- Power input options. Can be powered by a wheeled tractor, motor, or diesel engine.

- Reliable components. The crushing, separation, and cleaning devices are crafted using specialized mold stamping and welding techniques for durability.

In summary, the 5TZ-500 is an excellent solution for efficient pumpkin seed extraction, combining ease of use with robust performance features.

Structure of watermelon seed harvester

- Frame

- Feeding hopper

- Crushing box

- Separation barrel

- Cleaning barrel

- Seed rack

- Sprocket

- Chain

- Additional components

This assembly ensures efficient processing of seeds and enhances the overall functionality of the machine.

What are the features of the pumpkin seed collector’s structure?

- Durable steel frame. Constructed from high-quality steel, the welded frame ensures a strong and long-lasting structure.

- Efficient spiral cylinder. The unique spiral cylinder allows for easy removal of plants, such as vines and weeds, increasing overall work efficiency.

- Adjustable components. The crushing, extrusion, separation, and cleaning components are adjustable, enhancing the machine’s versatility for various tasks.

- Precision shaft system. Made from high-quality steel and processed after assembly, the shaft system provides high precision during operation.

These features make the pumpkin seed collector a robust and effective solution for seed extraction in agricultural applications.

Detailed information about the pumpkin seed collecting machine

| Model | 5TZ-500 |

| Size | 2000*1750*1450mm |

| Weight | 400kg |

| Working speed | 4-6km/h |

| Capacity | ≥500kg/h wet pumpkin seeds |

| Material container | 1.288㎡ |

| Cleaning rate | ≥85% |

| Breaking rate | ≤5% |

| Min power | 30hp |

| Max power | 50hp |

| Connect way | three-point linkage |

Working video of pumpkin seed extractor

Type 2: 5TZ-1500 melon seed extraction machine

The 5TZ-1500 melon seed extraction machine differs from the 5TZ-500 in output, design, and functionality. This advanced machine allows for the direct collection of pumpkins and watermelons in the field while simultaneously extracting seeds, making it highly efficient for agricultural operations.

Key features

- Direct field collection. This machine collects pumpkins and watermelons directly from the field while performing seed extraction.

- Automatic material handling. The machine gathers material as it moves forward, eliminating the need for manual feeding.

- Labor-saving convenience. The design minimizes labor requirements, enhancing operational convenience.

- Multi-functional operations. It can simultaneously perform various tasks, including picking, crushing, squeezing, separating, cleaning, storing, and unloading seeds.

- Efficient plant removal. Utilizing a unique suspension method and spiral cylinder, it effectively removes plants, saving time and improving work efficiency.

Overall, the big size melon seed extraction machine represents a significant advancement in seed extraction technology, combining multiple functions and reducing labor costs for farmers.

Components of the big pumpkin seed-extracting machine

The big pumpkin seed-extracting machine is composed of several essential components that work together to ensure efficient seed extraction. These components include:

- Frame.

- Melon picker.

- Seed extraction machine.

- Crushing box.

- Cleaning bucket.

- Lifting bucket tank.

- Seed storage box.

- Supporting wheel.

- Gearbox.

- Hydraulic line.

These components work harmoniously to optimize the process of seed extraction, making the big pumpkin seed-extracting machine a valuable asset for agricultural operations.

Specification of the pumpkin seed extractor

| Model | 5TZ-1500 |

| Size | 4800×4600×2200mm |

| Weight | 3388kg |

| Working speed | 2-5km/h |

| Capacity | ≥1500 kg/h wet watermelon seeds |

| Material container | 1.288㎡ |

| Cleaning rate | ≥85% |

| Breaking rate | ≤0.3% |

| Power | 60-90KW |

| Input speed | 540-720rpm |

| Connect way | three-point linkage |

Working procedures of pumpkin seed extractor

The pumpkin seed extractor operates through a series of streamlined procedures that efficiently process the seeds. Here’s a concise overview of the working steps:

- Collection and feeding. The self-weight of the melon barrel sends collected seed melons into the crushing box.

- Crushing. Blades and spirals on the crushing shaft break down the melons, transporting the crushed material to the seed extractor.

- Squeezing. The crushed melons are further squeezed by the cone bevel of the seed picker.

- Separation. The stirring action of the separation shaft discharges the rind and some flesh from the separation cylinder, allowing seeds and pulp to flow into the churning box.

- Feeding to cleaning drum. The stirring wheel shaft moves the seeds and flesh into the cleaning drum.

- Cleaning. The cleaning shaft rotates to separate and clean the seeds from the water and remaining flesh.

- Seed outlet. The cleaned seeds are squeezed out through the seed outlet.

- Storage. Cleaned seeds enter the storage box via a scraper-type lifting hopper.

- Discharge. When full, the storage box is lifted, and seeds are loaded into a transport vehicle through a pipeline.

These procedures ensure a highly efficient process for extracting and cleaning pumpkin seeds, maximizing productivity in agricultural operations.

What advantages does the melon seed extractor have?

- Sturdy frame. A square tube combination design ensures durability and stability.

- Optimized power distribution. A full-time power box enhances performance.

- Efficient seed picking. The double seed picker structure increases harvesting efficiency.

- Effective lifting mechanism. A scraper-type double lifting device speeds up material handling.

- Weeding capability. The tine box weeding mechanism cleans fields while operating.

- Large tying cylinder. A 1500 mm diameter cylinder improves melon tying efficiency.

- Real-time monitoring. An optional display monitor allows for better operational control.

- Enhanced mobility. Heavy-duty axle heads and high-pressure tires ensure stability in various conditions.

Packing and shipping of pumpkin seed extractor

This seed extractor is a hot sale in many foreign countries, such as Australia, Mexico, Philippines, Canada, USA, France, Morocco, Israel, South Africa, etc. Below are the pictures of the packing and shipping of the machine to Canada.

The customer sent us an email by visiting our website. In the email, the customer indicated that he needed a 5TZ-500 pumpkin seed extractor. So the sales manager immediately contacted the customer via email and provided a quotation.

During the communication process, the customer needed two additional screens with different mesh sizes. So we revised the quotation to the customer. After that, the customer decided to place an order.

Invest in our pumpkin seed harvester

We are committed to providing customers with outstanding solutions, ensuring that your investment yields maximum returns. Understanding the challenges in the agricultural field, our pumpkin seed harvester excels not only in performance but also in carefully crafted design to thrive in diverse and complex environments.

Contact us now to learn more about our pumpkin seed harvester and obtain customized solutions. Let us collaborate to propel your agricultural endeavors to new heights!