Plant transplanter machine 丨2/4 rows self propelled vegetable transplanter

A plant transplanter machine is equipment that can transplant various vegetable seedlings. Normally, the transplanters can transplant at least two rows at the same time. Also, vegetable seedling transplanters can work multi-rows once. So, there are various types of transplanters in the market now. And there are generally two types of vegetable transplanters: self-propelled and trailed. And before transplanting people usually use the nursery seedling machine to cultivate various seedlings. So, using this machine and transplanter can help farmers save much time and energy.

The power of the self-propelled transplanter is generally a gasoline engine. And trailed transplanters are working with tractors. Also, this type of seedling transplanter has various functions and can add functions such as rotary tillage, mulching, fertilization, watering, etc.

What is a vegetable transplanter?

We are manufacturer of the agro machines. So, we also design and produce the vegetable transplanter. We have two types of vegetable transplanters. And they are self-propelled vegetable transplanters and trailed transplanters. Among them, there are two different forms of self-propelled transplanters. One is the wheel-walking type, and the other is the crawler-walking type.

All of them can achieve simultaneous multi-row transplanting. Such as 2 rows, 4 rows, 6 rows, 8 rows, 10 rows, and 12 rows. And these automatic seedling planting machines can work on flat fields as well as in ridges. The self-propelled wheeled transplanter has no additional functions and all others can have additional functions. And the additional functions are fertilization, ridges, rotary tillage, watering, mulching, transplanting, and laying drip irrigation tape. So, the machine can achieve multi-functions.

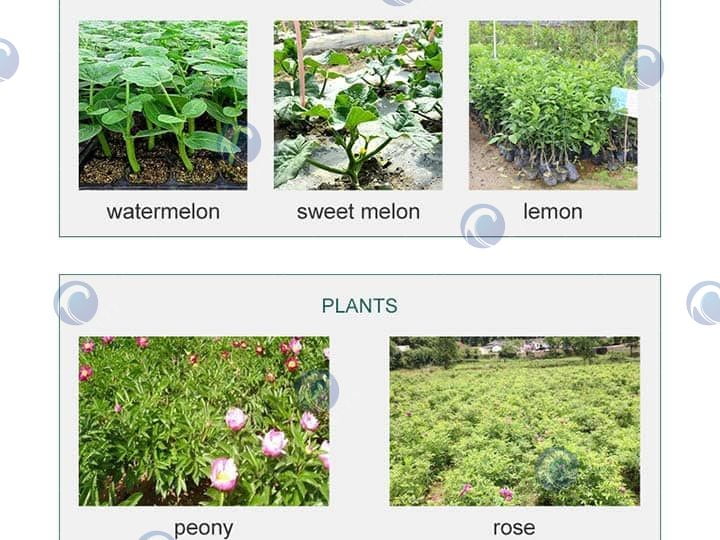

What seeds can the seedling tranplanter transplant?

Tomatoes, peppers, celery, onions, baby vegetables, broccoli, cabbage, carrots, coriander, hemp, tobacco, pumpkin, green beans, cabbage, fenugreek, etc. Besides these, there are other plants that can be transplanted. We will recommend suitable machines according to the specific seedlings of customers.

Type one: self propelled vegetable transplanter

This type of plant transplanter machine refers to the self-propelled wheeled transplanter. This self-propelled vegetable transplanter can transplant 2 rows or 4 rows at the same time. And its power is a gasoline engine. Because there are different requirements for row space. So we will customise the row space according to our customer’s needs. And the plant spacing is adjustable within a certain range. This type of machine has a smaller volume than other types. And it is lighter.

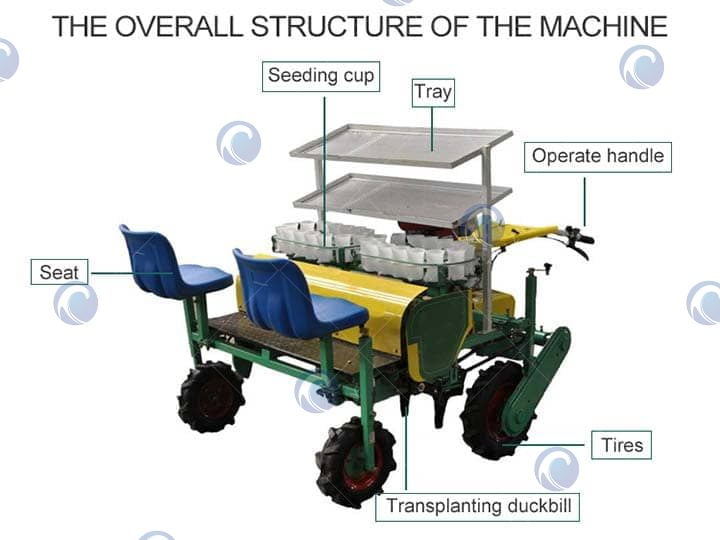

Structure of the self-propelled transplanter

The self-propelled plant transplanter machine mainly includes a seedling cup, seat, tray, frame, transplant device, and wheels. Its structure is not complicated. And the gasoline engine drives the machine forward. People sit on the seats and put the seedlings in the trays into the seedling cups. The seed cups are then moved into the soil by a transplanting mechanism.

How dose the transplanter machine work?

What is the technical parameter of the plant transplanter machine?

| Model | 2ZBZ-2 | 2ZBZ-4 |

| Plant spacing | 200-500mm | 200-500mm |

| Row spacing | 300-500mm | 150-300mm |

| Capacity | 1000-1400m²/h | 1400-2000m²/h |

| Row | 2 | 4 |

| Power | 4.05kw | 4.05kw |

Type two: self propelled transplanter (Crawler transplanter)

Self propelled transplanter with crawlers can transplant 4 rows, 6 rows, 8 rows, 10 rows, and 12 rows at one time. Besides, this plant transplanter machine can work with other functions that are mulching and laying drip irrigation tape. So, customers can choose these functions according to their needs. We support customization according to their requirements.

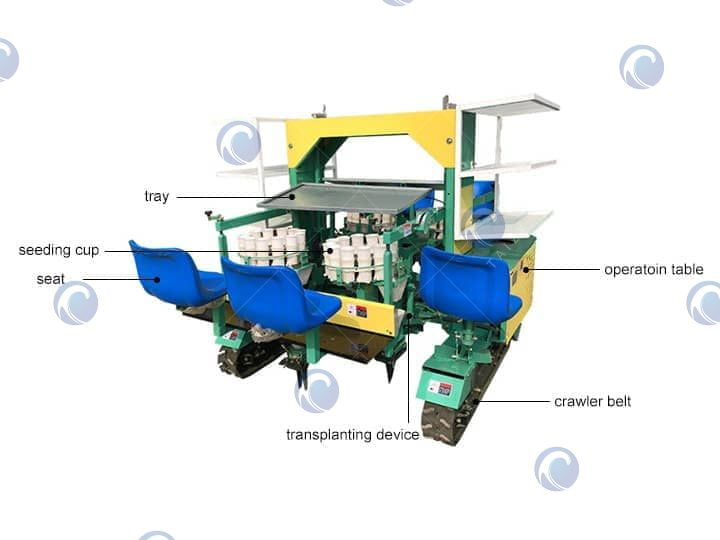

Structure of automatic onion transplanter

Compared to Type one, this automatic onion plant transplanter machine has a relatively complex structure. It has a frame, seat, seeding cup, tray, transplanter device, track, and operating system. Also, this automatic transplanter can have mulching and laying drip irrigation tape systems. So, these additional functions can save more time and effort.

Working video of the automatic seedling planting machine

What are the specific parameters of the plant transplanter machine?

| Model | 2ZBLZ-4 |

| Structure type | crawler self-propelled |

| Machine weight | 970kg |

| Supporting power | 4.05kw |

| Transmission mode | belt drive |

| Number of working rows | 4 rows |

| Working speed | 0.8-1.5 km/h |

| Plant spacing adjustment range | 200-450 mm |

| Depth adjustment range | 60-120mm |

Different points between Type one and Type two

- Power. Type one self-propelled wheeled plant transplanter machine can only work through the gasoline engine. But the self-propelled vegetable transplanter forwarding with crawlers can have the power from gasoline and diesel engine.

- Operation system. Type one transplanter is to control the forward direction through the hand-held system. But the second model is to control the machine through the operation table on one side.

- Row and plant spacing. Type two has wider row and plant spacing than Type one.

- Additional functions. Model one pumpkin transplanter cannot add other functions. In addition to the transplanting function, model two ridging plant transplanter machine can add the functions of both mulching and burying irrigation belts.

Type three: trailed transplanter

The trailed transplanter is driven by a tractor to operate. And the transmission is PTO. Also, this plant transplanter machine can till 2 rows, 4 rows, 6 rows, 8 rows, 10 rows, and 12 rows of seedlings at the same time. And, this multi-row plant transplanter machine can achieve more functions. These additional functions include fertilization, ridges, rotary tillage, watering, mulching, transplanting, and laying drip irrigation tape. So, these additional functions can meet more diverse needs. And we will recommend the suitable machine combination that is suitable for our customers.

What are the main components of the trailing vegetable transplanter?

The trailing vegetable transplanter without any additional functions has a simple structure. So, this type of automatic seedling planting machine has a seedling cup, seat, tray, frame, and transplant device. On the basic structure of the machine, we can add additional functions according to customers’ needs.

The working process of the trailing chili transplanter

What are the specifications of the vegetable plant transplanter?

| Model | 2ZBX-2 | 2ZBX-3 | 2ZBX-4 | 2ZBX-6 | 2ZBX-8 | 2ZBX-10 | 2ZBX-12 |

| Planting spacing | 200-500mm | 200-500mm | 200-500mm | 100-400mm | 100-400mm | 100-400mm | 100-400mm |

| Row spacing | 250-500mm | 250-300mm | 250-300mm | 150-300mm | 150-300mm | 150-300mm | 150-300mm |

| Capacity | 1000-1700m²/h | 1000-2000m²/h | 1000-2700m²/h | 1400-3400m²/h | 2000-4000m²/h | 2700-5400m²/h | 3700-6700m²/h |

| Row | 2 | 4 | 4 | 6 | 8 | 10 | 12 |

| Power | >=30 | >=30 | >=50 | >=60 | >=60 | >=60 | >=60 |

What are the advantages of a tractor vegetable seedling transplanter?

1. The plant transplanter machine works reliably and is easy to adjust. Because the transmission ratio of the machine is accurate. Also, the spacing of rice transplanting is accurate.

2. Long service life. The parts of the tomato transplanter are manufactured in strict accordance with the “international” high-strength raw materials. And the transplanter has stable performance with these parts.

3. The transplanter reduces labor intensity. And saves labor costs at the same time.

4. The quality of transplanting is greatly increased. So, the cost of transplanting is greatly reduced.

5. The crop growth and development period are the same. So it is convenient for farmers to implement field management.

6. Increase production and better economic benefits. Also, the transplanters achieve higher efficiency, labor-saving, and time-saving purposes.