Automatic rice milling machine production line

| Size | 3000*3000*3000mm |

| Total power | 23.3kw |

| Weight | 1400kg |

| Capacity | 600~700kg/h |

| Rice milling rate | 85%-90% |

The rice milling machine production line plays a pivotal role in the agricultural industry, revolutionizing the process of turning harvested rice paddy into edible rice for consumption. These machines are sophisticated pieces of equipment designed to efficiently remove the outer husk, bran layers, and impurities from raw rice grains, resulting in high-quality polished rice ready for market distribution.

Modern rice milling machines have become highly automated and precise, allowing for increased productivity and improved quality control. They come in various sizes and capacities to cater to the diverse needs of rice processing facilities, from small-scale operations to large commercial rice mills.

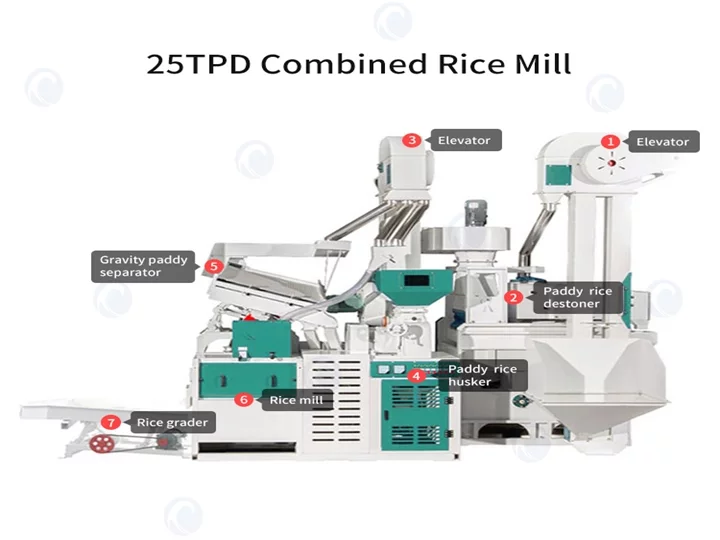

Main components of rice milling unit

- Elevator

- Introduction: The elevator is a vertical lifting device that transports raw paddy rice from one level to another within the milling process.

- Function: Its primary function is to efficiently lift and transfer the paddy rice to the subsequent processing stages. This component helps in the smooth flow of rice through the production line.

- Paddy Rice Destoner

- Introduction: The paddy rice destoner is a machine designed to remove stones, debris, and other impurities from the raw paddy rice.

- Function: Its main function is to ensure that the rice grains are free from any foreign material, such as stones or soil, which may have been mixed in during harvesting or transportation. This helps maintain the quality and safety of the final rice product.

- Paddy Rice Husker

- Introduction: The paddy rice husker is a machine designed to remove the outer husk layer from the paddy rice grains.

- Function: Its primary function is to separate the tough outer husk from the rice kernel, leaving behind the brown rice. This process prepares the rice for further milling and polishing.

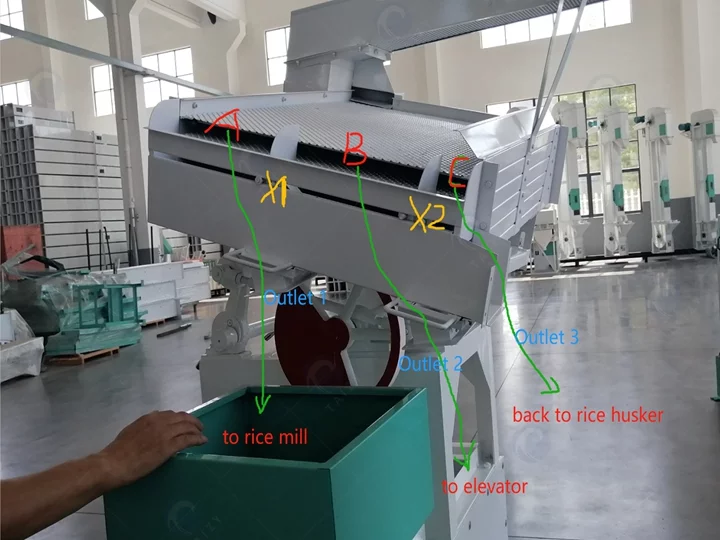

- Gravity Paddy Separator

- Introduction: The gravity paddy separator utilizes gravity and surface friction differences to separate brown rice from paddy.

- Function: It efficiently separates brown rice from paddy based on their distinct characteristics, enhancing the quality of the final product.

- Rice Mill

- Introduction: The rice mill is the central machine responsible for milling and refining the rice grains.

- Function: It processes the brown rice obtained from the husking stage, removing the bran layers to achieve the desired level of whiteness and texture.

- Rice Grader

- Introduction: The Rice Grader is a crucial machine used to separate whole rice grains from broken ones.

- Function: Its primary function is to grade the processed rice, distinguishing between whole rice grains and broken rice grains. This process ensures the quality and consistency of the final product. Through the Rice Grader, you can obtain rice products that meet specific standards, ensuring consumers receive high-quality rice.

Working process of the rice milling machine production line

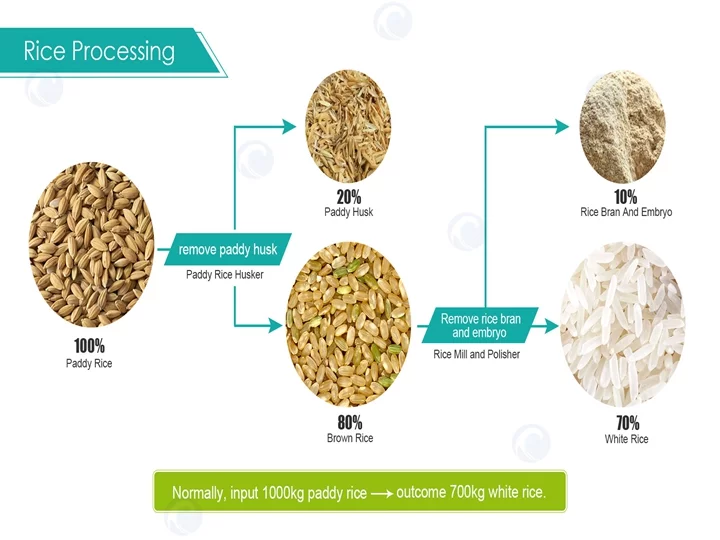

The paddy is conveyed by a single-chain elevator to undergo cleaning, de-stoning, and removal of debris and adjacent stones. It is then transported by a double-chain elevator to the husking machine for dehusking. The bran is either expelled by the fan or drawn into the pulverizer, while the mixture of bran and husk is conveyed by the double-chain elevator to the gravity sieve for separation.

Unhusked paddy from the gravity sieve is returned via the duct to the husking machine, while the brown rice enters the rice mill. After being whitened by the rice mill, it undergoes bran suction, flows into a separately matched broken rice sieve, and the finished product is collected and packaged after removing broken rice. The fine bran and bran are mixed and crushed in the pulverizer, and the composite bran is collected and packaged.

Rice milling units of different tonnages

15-ton Rice Milling Unit

Ideal for small to medium-sized rice processing facilities, this unit offers convenient operation and efficient processing capacity.

It can handle a moderate amount of paddy rice, making it suitable for small farms or small-scale processing businesses. With its user-friendly operation and easy maintenance, it allows you to start rice processing with ease.

| Item | Power(kw) |

| Elevator | 0.75 |

| Paddy Rice Destoner | 0.75+0.75 |

| Paddy Rice Husker | 4 |

| Gravity Paddy Separator | 0.75 |

| Rice Mill | 15 |

| Rice Grader | 0.55 |

20-ton Rice Milling Unit

This 20-ton rice milling unit is a powerful equipment equipped with a cleaning machine featuring a cylindrical sieve structure. This ensures the thorough removal of impurities during the rice processing, guaranteeing a high-quality end product.

It is suitable for medium-sized rice processing facilities and is particularly well-suited for consumers who value premium quality rice.

| Item | Power(kw) |

| Elevator | 0.75 |

| Pre-cleaner | 0.55 |

| Paddy Rice Destoner | 1.1+1.5 |

| Paddy Rice Husker | 4 |

| Gravity Paddy Separator | 0.75 |

| Rice Mill | 15 |

| Rice Grader | 0.55 |

25-ton Rice Milling Unit

The 25-ton rice milling unit features an enlarged destoner with a flat structure and an internal rotary sieve. This enhances the efficiency of removing stones and impurities from the rice.

If you require a large output of high-quality rice, this unit is an excellent choice. It is designed for large-scale rice processing facilities and is ideal for commercial production.

| Item | Power(kw) |

| Elevator | 0.75 |

| Paddy Rice Destoner | 1.1+2.2 |

| Paddy Rice Husker | 5.5+1.1 |

| Gravity Paddy Separator | 0.75 |

| Rice Mill | 18.5 |

| Rice Grader | 0.55 |

30-ton Rice Milling Unit

The 30-ton rice milling unit is the largest model, with increased dimensions for each machine. This means it can handle even larger batches of paddy rice, offering high production capacity.

If you need to produce a substantial quantity of high-quality rice, this unit is the ideal choice. It is suitable for large-scale rice processing facilities or grain processing businesses.

| Item | Power(kw) |

| Elevator | 1.1 |

| Paddy Rice Destoner | 0.5+3 |

| Paddy Rice Husker | 5.5+1.1 |

| Gravity Paddy Separator | 1.1 |

| Rice Mill | 18.5 |

| Rice Grader | 0.55 |

Whether you are operating a small family farm or a large-scale grain processing enterprise, our range of rice milling units provides efficient and convenient solutions to ensure you obtain high-quality finished rice.

Key features and advantages of the rice milling production line

- This machinery adopts a combination arrangement to enhance its visual appeal and compactness. The inclusion of anchor screws in the eccentric rotating part provides added stability.

- The critical operational components of the machine have undergone significant improvements. Some parts have been lowered to facilitate easier operation, especially for individual farmers. The machine’s most prominent advantage lies in its user-friendliness.

- Each individual component of this equipment can be assembled and disassembled separately, streamlining maintenance and transportation.

- A suction-type destoner is employed in this machine, ensuring a more reliable and steady destoning process. This also reduces dust emissions during the feeding process, creating a more favorable working environment.

- Designed to accommodate both individual farmers’ processing needs and the continuous processing of commercial grains, this machine represents a new generation of advanced rice milling equipment with dual functionality.

- A grinding process has been integrated into this equipment. This enables farmers to blend large bran with clean bran for one-time processing into uniform bran powder, maximizing the utilization of by-products. Furthermore, it retains the method of extracting large bran in a single step, while solely collecting clean bran, offering users a convenient choice.

Why does rice need to be milled?

The outer layer of brown rice is rich in rough fiber, making it less digestible for the human body. Additionally, brown rice has a lower capacity to absorb water and expand.

This not only prolongs the cooking time and decreases the rice yield, but also results in a darker hue, lower viscosity, and less appealing flavor. Hence, it is crucial to undergo the rice milling process to remove the outer layer of brown rice.

What’s the best humidity of the paddy rice for milling?

The ideal moisture content for paddy rice is 14.5%, with a desired rice breakage rate of approximately 2% during the milling process. If the moisture content falls below 14.5%, the breakage rate tends to increase.

Conversely, if the moisture content exceeds 14.5%, the breakage rate also rises, and there is a risk of paddy husk and bran obstructing the machinery, potentially leading to operational disruptions or even motor damage.

Conclusion

As a leading supplier of rice milling machinery, we are committed to providing state-of-the-art and efficient rice mill machine plants. Our rice milling machines boast exquisite craftsmanship and outstanding performance, injecting new vitality into your rice processing production line.

Whether you require a small-scale home rice mill or a large-scale commercial rice mill plant, we have tailored solutions to meet your needs. We prioritize quality above all else, ensuring reliable, high-quality products and services for our customers. Feel free to contact us for more information and to request a quote.