Grass chaff cutter丨Fodder cutter machine

Grass chaff cutter is our company’s self-developed straw processing machinery. It is a new type of coarse feed processing machine integrating cutting and kneading. The machine has the characteristics of advanced performance, reasonable structure, and a wide range of applications. Also, its processing material performance and processing quality are at an advanced level.

It is mainly used for processing crushed grass, such as corn stalks, peanut seedlings, sweet potato vines, royal bamboo grass, sweet elephant grass, sugar cane, and so on. This grass chaff cutter is wet and dry equipment, so whether it is green grass material or dry grass material can be processed.

Introduction of grass chaff cutter

We produce different models of grass chaff cutters. Customers can choose the machine model according to their needs. The machine models are different and the output is also different.

Regarding the power of the machine, the power can be an electric motor, diesel engine, or gasoline engine.

What’s more, each model of our fodder cutter machine has a conveyor belt, which can automatically feed the material into the cutting chamber. This helps to improve the efficiency of the machine and save labor.

Also, we have the silage baler machine, which can bale processed silage automatically. Here are our machines for each model.

Application scope of the fodder cutter machine

The fodder cutter machine is mainly used for making feed for pigs, cattle, sheep, horses, donkeys, mules, rabbits, chickens, ducks, geese, and other poultry and livestock.

The machine can handle corn straws, cereal straws, rice straws, bean straws, peanut vines, alfalfa, and other materials.

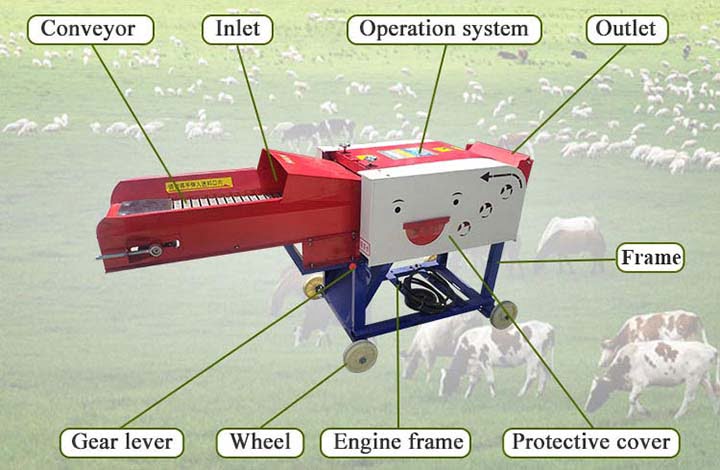

Structure of chaff cutter machine

The main components of the chaff cutter mainly include a conveyor, inlet, cutting and kneading room, outlet, frame, gear lever wheels, engine frame, protective cover, etc.

Working video of grass chaff cutter

Different types of grass chopper machine parameters

| Model | Power | Capacity | Size | Weight |

| 9ZR-2.5T | 3-4.5kw electric motor | 2500kg/h | 1350*490*750mm | 67kg |

| 9ZR-3.8A | 3-4.5kw electric motor | 3800kg/h | 1650*550*900mm | 88kg |

| 9ZR-3.8B | 3-4.5kw electric motor | 3800kg/h | 1750*550*900mm | 93kg |

| 9ZR-4.8T | 5.5kw electric motor | 4800kg/h | 1750*600*930mm | 116kg |

| 9ZR-6.8 | 7.5kw electric motor | 6800kg/h | 2283*740*1040mm | 189kg |

| 9ZR-8 | 11kw electric motor | 8000kg/h | 3400*830*1200mm | 320kg |

Why do we need to use a grass chaff cutter to process materials?

The stems to be processed include corn stalks, cereal straw, rice straw, beanstalks, peanut vines, alfalfa, etc., which are rich in crude cellulose, vitamins, minerals, crude protein, etc., and are natural feed for livestock.

However, unprocessed plant stems are not easily digested and absorbed by livestock due to their natural form and hard cortex, so they need to be further processed.

Mechanical methods are used to change the form of plant stems to make them suitable for livestock consumption. In the mechanical processing equipment for plant stems, one of the commonly used is cutting and crushing machinery. It is to cut the plant stems into small sections, and then hammered and kneaded by mechanical devices to form a soft, short, shredded forage.

This form of feed can improve the palatability of livestock consumption, and is conducive to the digestion and absorption of nutrients, thus greatly improving the utilization rate of forage.

What are the advantages of the fodder cutter machine?

- The grass chaff cutter is mainly composed of feeding the frame, housing, rotor, and other components. It has the advantages of reasonable structure, convenient operation, and high production efficiency.

- This series of products changed the previous chaff cutter machine’s simple blade cutting principle, the use of cutting, knocking, kneading, rubbing, and other physical effects of the material into a uniform length, soft and fine shredded, while there is an increase in the automatic feeding device, effectively preventing the blockage and uneven feeding phenomenon.

- The machine integrates the cut and shredder with one, the whole machine consists of the guillotine, hammer blade, and wind blade three parts crushing, guillotine, and other functions.

- Compact structure, small volume, and small weight.

- The machine’s high output, simple structure, easy operation, and processing of a wide range of characteristics.

- Double-sided thickened large blades, plus 32 double-sided kneading knives, can be thoroughly broken grass kneading into silk, improving the cattle and sheep feeding, the grass is basically all used to save the cost of breeding.

Maintenance of grass chaff cutter

- Before and after the operation, regularly inspect all fasteners to prevent loosening and potential damage to the machine.

- During operation, add an appropriate amount of 30# engine oil to each oil injection hole every 2 hours. Lubricate bearing positions with grease once a day to ensure proper lubrication during work.

- While in operation, sharpen the moving and fixed blades every 6 hours of work to maintain sharpness.

- After stopping the operation, promptly clean the machine of weeds and dust, lubricate all lubrication points, and store it in a dry warehouse if not in use for an extended period to prevent corrosion from exposure to wind and rain.

Successful case

Last week our customer from Kazakhstan bought a 9ZR-3.8B chopper cutter from us. The customer requested the machine to be powered by a diesel engine. The customer is from Alibaba, our sales manager saw the customer sent a grass chopper machine inquiry, and immediately communicated with the customer.

Through understanding that the customer had imported the machine from China, he had import experience and knew more about the machine. Therefore, the entire purchase process was relatively quick. The following is a picture of the packaging of the machine for shipment.

Invest in our chaff cutter machine

In the realm of modern agriculture, the Chaff Cutter Machine stands as an indispensable tool for enhancing efficiency and streamlining farm operations. Its innovative design and exceptional performance guarantee optimal results in the processing of fodder.

Whether you’re a large-scale farmer or a smallholder, this machine caters to your needs, elevating your agricultural production to new heights.

If you find yourself intrigued by the Chaff Cutter Machine and wish to learn more details or receive a customized quote, feel free to reach out to us. Our dedicated team is ready to provide full support, ensuring you choose the model that best suits the requirements of your farm.

Don’t miss the opportunity to boost agricultural productivity – contact us now and embark on a new chapter in modern farming!