Hydraulic hay baler | Hydraulic silage press baler

| Model | 9YK-70 |

| Power | 15kw motor or 28HP diesel engine |

| Bale size | 700*400*300mm |

| Bale density | 300-400kg/h |

| Weight | 1500kg |

| Dimension | 3400*2800*2700mm |

The hydraulic hay baler is suitable for animal husbandry, cattle and sheep breeding, and forage distribution. It uses hydraulic pressure to compress materials such as straw, hay, and pasture grass into dense, uniform bales.

With a high efficiency of 80–90 bales per hour, it greatly enhances productivity in agricultural and livestock operations. The finished bales are compacted into special packaging bags with a standard bale size of 70×40×30 cm, making them easy to stack, transport, and store.

By significantly reducing the volume of loose materials, this baler helps lower transportation costs and improve overall handling efficiency. As an environmentally friendly solution, it contributes to better resource utilization and waste reduction, delivering both ecological and economic value to modern farms.

Hydraulic hay baler for sale

Our hydraulic hay baler for sale is a powerful and practical solution for compressing straw, pasture grass, and forage into compact rectangular bales. With a finished bale size of 700×400×300 mm, this machine helps reduce storage space, improve transport efficiency, and lower fire risk—making it an ideal choice for livestock farms and forage processing businesses.

We offer two main types of hydraulic hay balers to meet different needs:

Two-cylinder hydraulic hay baler

- Power options: Diesel engine or electric motor.

- Suitable for flexible work environments, including outdoor and remote areas.

Three-cylinder hydraulic hay baler

- Power option: Electric motor only.

- Offers higher baling efficiency, ideal for large-scale silage packing operations.

When operating the machine, a double-layer PE+PP silage bag is placed at the discharge outlet in advance.

The compressed forage is directly packed into the bag, keeping the bale tightly sealed.

This design not only maintains feed freshness but also reduces volume for easier handling and safer storage.

Additionally, we provide round silage baler machines for customers who prefer circular bale packaging.

If you’re looking for a hydraulic hay baler for sale with strong performance and customizable options, feel free to contact us for a quote and professional guidance!

What materials can the silage press baler process?

The silage press baler is a versatile machine designed to handle a wide range of agricultural and biomass materials. It can efficiently compress and bale various types of green and dry forage, crop residues, and agricultural by-products—making it an essential tool for modern livestock farming and biomass utilization.

Supported materials include:

- Compressed peanut seedlings

- Alfalfa

- Pasture grass

- Wheat grass

- Peanut seedlings

- Crop straw

- Peanut shells

- Cottonseed hulls

- Corn cobs

- Kneaded or crushed corn straw

Once these materials are baled and sealed in special packaging bags, the storage space required is greatly reduced, and the shelf life of green forage is extended—providing year-round feed availability for livestock.

Moreover, after sealing, the bales undergo natural fermentation, producing probiotics and beneficial bacteria that enhance the nutritional value of the feed. This fermented silage is more easily absorbed by cattle and sheep, and studies show that it can increase livestock growth rates by up to 2%.

In addition to improving feed efficiency, the baler also helps reduce transportation and storage costs, while lowering labor intensity, resulting in significant economic benefits for the livestock industry.

Widely applicable in industries such as:

- Biomass power generation (straw fuel)

- Animal husbandry

- Cattle and sheep breeding

- Forage processing and distribution

- Paper manufacturing (using agricultural fiber)

Type 1: two-cylinder hydraulic hay baler

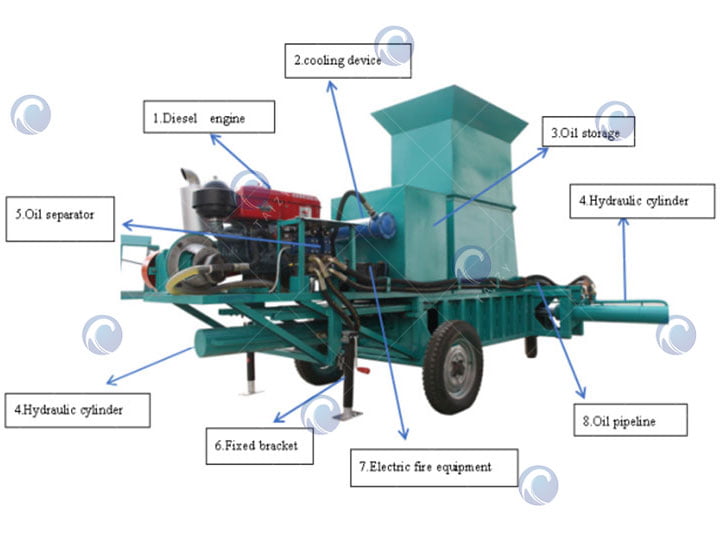

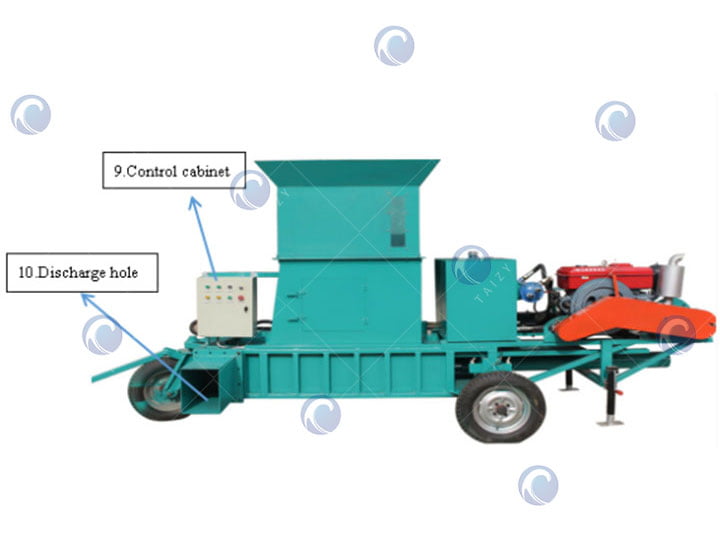

This model of machine mainly includes power, cooling device, oil storage, hydraulic cylinder, oil separator, fixed bracket, electric fire equipment, oil pipeline, etc.

Functions of the different parts

- Hydraulic system

- Includes oil tank, control valves, filter unit, and accessories. The oil cylinder stores and supplies hydraulic oil for machine operation.

- Main pressure system

- Consists of a main cylinder and bale pusher to compress and discharge materials efficiently.

- Mainframe

- Made up of a fixed and movable box. The fixed box handles compression, while the movable side uses dual clamping cylinders. The side plate is welded from high-strength rail steel for better rigidity.

The working principle of the hydraulic press machine

The hydraulic press machine operates through a streamlined process that integrates raw material feeding, crushing, compressing, and packaging.

- Material feeding

- Grass, straw, or other raw materials are fed into the machine either manually or via a conveyor belt.

- Crushing and kneading

- A hay cutting machine or straw kneading unit crushes and grinds the input materials, preparing them for efficient compression.

- Bag placement

- Before discharging, a straw bag is positioned at the outlet to collect the compressed material.

- One-key operation

- With an automatic control cabinet, the machine starts with a single button, enabling easy and fast processing.

- Consistent output

- The finished bales are uniform in size and volume, meeting packaging standards and making storage and transportation more convenient.

Parameters of the hydraulic baler machine

| Model | 9YK-70 |

| Power | 15kw motor or 28HP diesel engine |

| Displacement of oil cylinder | 63-80L/min |

| Normal-pressure of oil cylinder | 16Mpa |

| Bale size | 700*400*300mm |

| Bale Density | 300-400kg/h |

| Bundling efficiency | 1-2t/h |

| Weight | 1500kg |

| Dimension | 3400*2800*2700mm |

| Speed of Bundling Piston | 4-8m/min |

Advantages of the press baler machine

- Dual operation modes: Supports both semi-automatic and fully automatic modes, easy to switch and labor-saving.

- Wide material compatibility: Suitable for corn cobs, rice straw, peanut seedlings, wheat straw, cottonseed hulls, peanut shells, and other shredded agricultural waste.

- Efficient compression: Greatly reduces material volume for easier storage and lower transportation costs.

- Special packaging: Uses durable silage bags to improve compression results and preserve material quality.

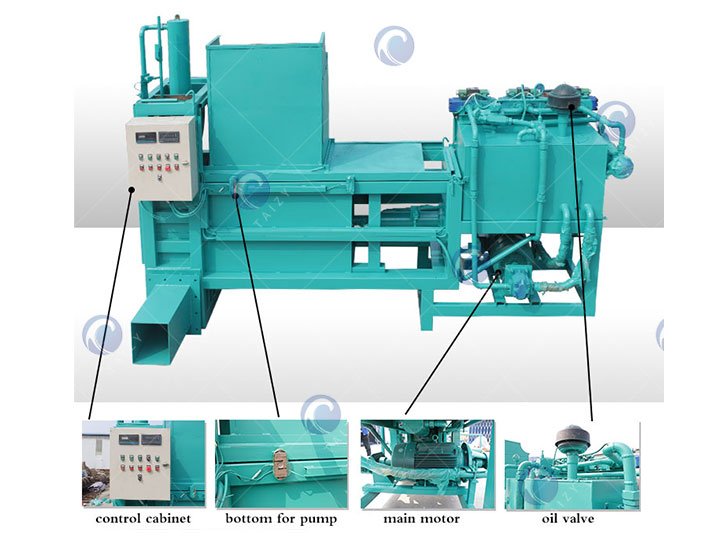

Type 2: three cylinders hydraulic baler

This model offers higher efficiency compared to Type 1, with a processing capacity of 6–8 tons per hour. It is powered by a 22 kW electric motor and classified as a fully automatic straw hydraulic baler.

The machine operates through a coordinated system of four hydraulic cylinders and a stroke switch, completing the shredding and baling process automatically. The operator only needs to handle bag placement and tying, significantly reducing manual labor.

Specification of the hydraulic hay baler machine

| Item | 9YK-130 |

| Power | 22kw |

| Displacement of Oil Cylinder | 80L/min |

| Normal Pressure of Oil Cylinder | 18Mpa |

| Bale Size | 700*400*300mm |

| Bundling Efficiency | 6-8t/h |

| Bale Density | 800-1100kg/m3 |

| Weight | 2600kg/h |

| Dimension | 4300*2800*2000mm |

| Speed of Bundling Piston | 4-8m/min |

How does the hydraulic hay baler work?

The stalk press baler operates in a step-by-step compression process to ensure dense and uniform bales:

- The main hydraulic cylinder pushes horizontally to compact the material.

- The side cylinder then applies vertical pressure for further compression.

- Finally, the pushing head drives the compacted bale into the pre-positioned bag for sealing and storage.

This coordinated process ensures high bale density and efficient packaging.

What are the features of the hydraulic hay baler?

- High efficiency of the machine, it can process 6-8t of straw, grass, etc. per hour.

- The material used to manufacture the machine is of high quality. So, it is durable and long service life.

- The machine has a wide range of use. And can handle many kinds of materials.

Optional pieces of hydraulic hay baler

These two models’ machines can work with a chaff cutter, conveyor belt, mixer, and crusher. Since the material to be handled needs to be crushed, we can match it with the chaff cutter to crush the material first.

In order to let different kinds of materials can be fully mixed, we can also use the mixer to mix the materials. Then the fully mixed materials are fed into the inlet of the machine through the conveyor belt.

Conclusion

In summary, the hydraulic hay baler offers a reliable, high-efficiency solution for compressing and packaging various agricultural materials such as straw, hay, and forage.

With its powerful hydraulic system, automated operation, and consistent bale size, it significantly reduces labor intensity, improves storage and transportation efficiency, and supports natural fermentation for enhanced feed quality.