Screw oil press machine | Hydraulic oil press machine for peanut

| Model | 6YL-80 |

| Main power(kW) | 4 |

| Capacity(kg/h) | 80-120 |

| Weight (kg) | 880 |

| Size (mm) | 1700*110*1600 |

We offer four types of screw oil press machines to cater to diverse user needs: semi-automatic, fully automatic, cold and hot press, and hydraulic press. With a processing capacity ranging from 40 to 350 kg/h, these machines are designed to deliver exceptional performance and efficiency.

Our oil press machines are not limited to traditional materials like peanuts; they can also efficiently extract oil from sesame, soybeans, rapeseed, and many other oilseeds. Featuring high efficiency, energy savings, user-friendly operation, and excellent production capacity, these machines are the ideal choice for the oilseed processing industry.

What materials are suitable for oil extraction machine?

- Sunflower seeds. Sunflower seeds contain a significant amount of oil and are commonly used for oil extraction. Sunflower oil is known for its light flavor and high smoke point, making it suitable for frying and cooking.

- Rapeseeds (Canola). Rapeseeds, which are also known as canola seeds, are widely used for oil extraction. Canola oil is low in saturated fat and has a neutral flavor, making it suitable for various culinary applications.

- Peanuts (Groundnuts). Peanuts are rich in oil and are commonly used for oil extraction. Peanut oil has a distinctive flavor and is often used in Asian cuisines.

- Sesame seeds. Sesame seeds are known for their high oil content and are commonly used for oil extraction. Sesame oil is prized for its nutty flavor and is used in various cuisines worldwide.

Type 1: Hydraulic oil press machine

Working principle:

The hydraulic oil press machine uses liquid as the medium for pressure transmission, generating working pressure to squeeze oil into the cake ring.

Model options:

- We offer four models to meet varying capacity needs.

- Popular models: 6YZ-180, 6YZ-230, and 6YZ-260.

- Powered by a motor for efficient operation.

Enhanced oil quality:

A separator is used during material placement to ensure thorough squeezing.

Results in:

- Fewer impurities in the final oil.

- Superior oil quality.

- High cake value for secondary use.

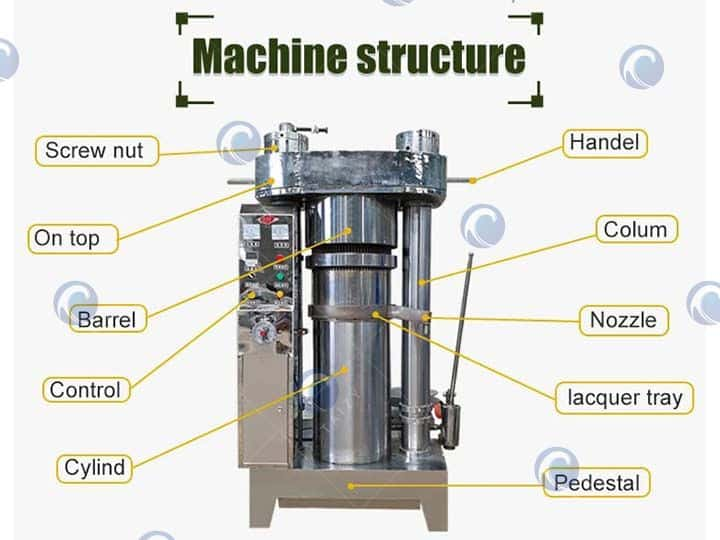

Structure of sesame oil press machine

Key components: upper top plate, distribution box, pressure gauge, base, reinforcement ring, material barrel, oil receiving plate, oil cylinder, plunger.

Features:

- compact structure

- attractive and modern design

- space-saving with a small footprint

- optimized for effective sesame oil extraction

Automatic hydraulic oil press machine’s working flow

- Preheating:

- Before each oil extraction, preheat the machine.

- Summer and autumn: 70-80°C

- Winter and spring: 80-100°C

- Before each oil extraction, preheat the machine.

- Machine preparation:

- Run the machine 1-2 times before oil extraction for 5-10 minutes with air to thin the hydraulic oil, ensuring smooth operation.

- Oil extraction process:

- Place the fried oilseeds into the press chamber.

- When the oil level is slightly below the upper-end face, add the separator.

- During the boosting process, ensure the machine is monitored at all times.

- Once no oil seeps from the pressing chamber’s oil joint, the extraction is complete.

- Completion:

- Turn off the machine and remove the oil cake.

Detailed information on hydraulic oil presser

| Model | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| Size(mm) | 920*480*1190 | 1065*540*1550 | 900*1000*1560 | 980*1050*1680 |

| Weight(kg) | 450 | 880 | 1250 | 1680 |

| Kg pressure(kn) | 1600 | 2200 | 2600 | 3000 |

| Max working pressure | 55Mpa | 55Mpa | 55Mpa | 55Mpa |

| Electric heating power(kw) | 1 | 1 | 1.2 | 2 |

| Weight of sesame seeds(kg) | 2-4 | 5-8 | 6-10 | 7-18 |

| Power(kw) | 3(220v) | 1.5 | 1.5 | 2.2 |

What are the machines that can work with the home hydraulic oil press?

There is a sesame screening machine, sesame roasting machine, centrifugal oil filtering machine, almond and peach nut cracker machine, an elevator, etc.

These machines can form a complete production line. You can achieve more efficient and convenient work. So, you can choose the right machine according to your needs.

The outstanding features of professional hydraulic oil expeller

- High efficiency, environmentally friendly, energy-saving, and delivers high-value products.

- Operates quietly with a physical pressing method that requires no heating or chemical additives.

- User-friendly design with durable components, ensuring easy operation and a long service life.

- The hydraulic oil press stands out for its exceptionally high pressure, enabling optimal oil extraction.

Type 2: Automatic screw oil press machine

Machine models:

- Available in five models based on screw diameter: 6YL-60, 6YL-70, 6YL-80, 6YL-100, 6YL-125.

Hot pressing features:

- Hot-pressed oil is more fragrant with a richer color.

- Materials are pre-heated before pressing.

Power source:

- Operated by a motor for consistent performance.

Adjustable pressing:

- Residual material is discharged at the end of the screw.

- The material extrusion degree can be adjusted using the handle in front of the hopper.

Oil filtration system:

- Equipped with an oil filter barrel.

- Uses a layer of oil filter paper to remove impurities.

- Employs vacuum oil filtering to create negative pressure, allowing outside air to press the oil into the barrel.

Performance advantage:

- Offers a higher oil extraction rate compared to semi-automatic models.

Automatic screw oil press machine’s parameter

| Model | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| Screw diameter(mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| Screw rotating speed(r/min) | 64 | 38 | 35 | 37 | 34 |

| Main power(kW) | 2.2 | 3 | 4 | 7.5 | 15 |

| Vacuum pump power(kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| Heating power(kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| Capacity(kg/h) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| Weight(kg) | 220 | 280 | 880 | 1100 | 1400 |

| Size(mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

Type 3: Screw oil press machine for peanut

Oil pressing mechanism:

- Similar to Type 2, the pressing part is designed for efficient oil extraction from peanuts.

Added feature:

- Equipped with a screw feeder that enables material circulation.

Cold pressing advantages:

- Nutrients in the oil are preserved without being destroyed.

- Cake can be pressed multiple times due to the lower oil yield.

Oil characteristics:

- Hot-pressed oil has a darker color.

- Cold-pressed oil has a lighter color.

Power source:

- Operated by a motor for reliable performance.

What is the specification of the oil press machine?

| Model | ZY-125 | ZY -150 |

| Motor | 15kw | 37kw |

| Vacuum pump motor | 1.5kw | 2.2kw |

| Capacity | 150-200kg/h | 300-350kg/h |

| Weight | 986kg | 2500kg |

| Size | 1900*1100*1500mm | 2100*1300*1700mm |

Type 4: Semi-automatic screw oil press machine

The semi-automatic screw oil press machine has not any other accessories. It only has the part that can extract oil. The structure and operation of the machine are also simpler.

The power of this semi-automatic oil press can be an electric motor and a diesel engine. Customers can choose the power according to their own needs. So, machines of this model are also more affordable.

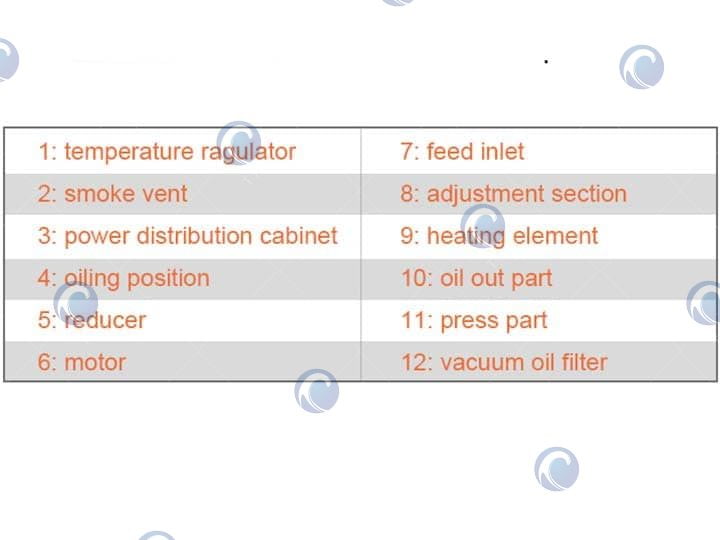

What is the structure of single screw oil press machine?

The core structure of Type 2 and Type 4 is similar, including material inlet, adjustment section, heating element, press part, oil out part, power(motor, diesel engine), etc.

Two sets of oil expellers sold to Angola

Last week we had a customer from Angola. He wants to start an oil pressing project. And through Alibaba, he gets our contact information and sends an inquiry to us.

This customer wants to press Soybean oil. Also, according to his need for output, we recommend the ZY-150 model to him. Finally, he bought two sets of oil press machines.

Contact us now!

In conclusion, the screw oil press machine offers a highly efficient and reliable solution for extracting premium oil from a variety of oilseeds, including peanuts.

For a more streamlined operation, it can be seamlessly paired with a peanut sheller machine for efficient dehusking and a peanut harvesting machine for collecting raw materials. Together, these machines provide a complete and optimized system for your oil production process.

For more information or to get a quote, feel free to contact us today!