Maize sheller machine | High capacity corn threshing machine

| Model | 5TY-80D (with elevating feeder and conveyor) |

| Power | 15HP diesel engine or 7.5 KW motor |

| Capacity | 6t/h (Corn seeds ) |

| Threshing rate | ≥99.5% |

| Weight | 350kg |

| Size | 3860*1360*2480 mm |

The Maize Sheller Machine is a high-efficiency corn threshing equipment that streamlines the post-harvest process for farmers and grain processors.

Capable of processing up to 6 tons of dry maize per hour, this machine ensures an impressive shelling rate of over 99.5% with a damage rate of less than 1.5%. It combines shelling, separating, cleaning, and grain discharge into one smooth operation.

Powered by either a diesel engine or electric motor, the maize sheller machine features a conveyor feeding system, cyclone discharger, and adjustable components to suit various working conditions.

Maize sheller machine for sale

Maize sheller machine for sale – designed to efficiently remove corn kernels from the cob in large quantities. This versatile machine supports both diesel engine and electric motor options, allowing it to meet the diverse power needs of customers in different regions.

To further enhance convenience, optional attachments such as a grain conveying pipe and conveyor belt are available, helping to significantly reduce manual effort during operation.

In addition to the dry corn sheller, we also offer a fresh corn threshing machine specially made for processing undried corn, providing more flexibility for different harvesting conditions.

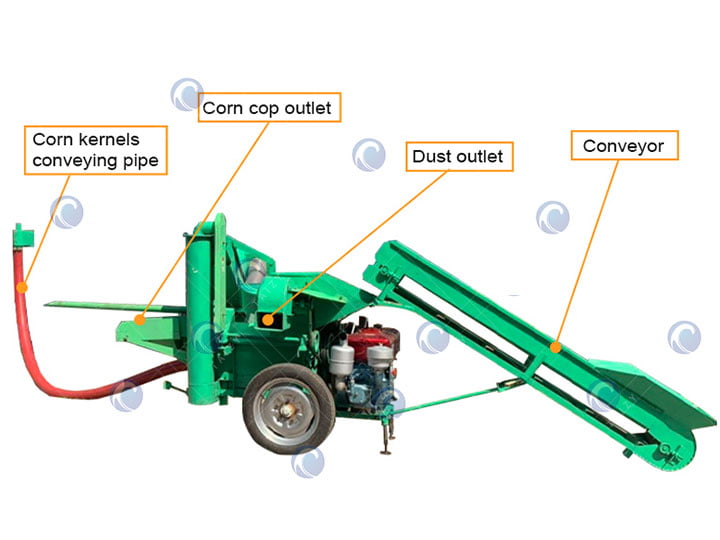

Structure of the maize sheller machine

The maize sheller machine features a well-designed structure that ensures efficient corn threshing and easy operation. It is built with durable components that work together to separate corn kernels from the cob while minimizing labor effort.

- Corn inlet – Where the maize is fed into the machine.

- Internal threshing and rolling device – Responsible for detaching the kernels from the cob through high-speed rotation and friction.

- Corn kernel outlet – Discharges the separated kernels after processing.

- Corn cob outlet – Expels the empty cobs separately to keep the process clean and efficient.

- Power system – Equipped with either an electric motor or a diesel engine to suit different power availability.

- Machine frame – Provides a stable base to support all components during operation.

Optional equipment: To further improve working efficiency, the maize sheller machine can be equipped with a conveyor belt and a grain conveying pipe. The conveyor belt simplifies the feeding process by automatically delivering corn to the threshing chamber, reducing the need for manual handling.

Meanwhile, the grain conveying pipe allows for centralized collection and transport of the shelled kernels to a designated location. Both additions help save labor and make the overall operation more convenient and streamlined.

Specification of commercial corn sheller

| Model | 5TY-80D (with elevating feeder and conveyor) |

| Power | 15HP diesel engine or 7.5 KW motor |

| Capacity | 6t/h (Corn seeds ) |

| Threshing rate | ≥99.5% |

| Loss rate | ≤2.0% |

| Breakage rate | ≤1.5% |

| Impurity rate | ≤1.0% |

| Weight | 350kg |

| Size | 3860*1360*2480 mm |

Working procedure of corn shelling machine

- Corn feeding onto conveyor belt

- The user starts by placing the corn onto the conveyor belt of the maize sheller machine.

- Conveyor belt delivery to threshing chamber

- The conveyor belt moves continuously, carrying the corn and delivering it into the threshing chamber of the machine.

- Threshing action inside the chamber

- Once in the threshing chamber, the corn encounters the iron roller and the screen.

- The iron roller rotates and, through its interaction with the screen, applies friction and impact forces to the corn. This action threshes the corn, loosening the kernels from the cobs.

- Separation of corn cobs and kernels

- After threshing, the machine’s internal mechanisms, which may rely on factors like size, shape, and weight differences, separate the corn cobs from the kernels.

- Discharge from corresponding outlets

- The separated corn kernels exit the machine through the designated kernel outlet.

- The corn cobs are discharged from the cob outlet, completing the shelling process.

Advantages of the automatic corn threshing machine

- Multiple functions in one step – This machine integrates threshing, separation, cleaning, and stacking, completing all tasks in a single operation.

- High efficiency – With an output of up to 6 tons per hour, it greatly improves productivity.

- Excellent performance – It ensures a high kernel removal rate and delivers a clean final product.

- Durable construction – Built with high-quality materials, the machine is sturdy and reliable for long-term use.

- Efficient grain transport – The optional grain conveying pipe helps deliver corn kernels directly to a designated location, reducing labor and increasing convenience.

Installation and adjustment of industrial corn sheller

- Install the diesel engine on the frame. Adjust the screw rod to tighten or loosen the belt. Unscrew the separation screw to lift the engine, loosen the belt, and allow no-load starting.

- Check belt tension for the spindle, auger, elevator, and fan. Ensure all belts are moderately tight.

- Adjust the vibrating screen angle by changing the height of the two support frames to control impurity discharge speed.

- Set up the impurity outlet. Tie a large woven bag below the screen to collect discharged impurities.

- Stabilize the machine by adjusting the support rods under the diesel engine until the wheels are nearly off the ground for stable operation.

Contact us now!

Our maize sheller machine offers exceptional efficiency and durability. With options for diesel or electric power and additional accessories like conveyor belts and grain pipes, this machine can be customized to fit your specific needs and improve your corn processing workflow.

Besides the maize sheller, we provide a full range of corn processing equipment, including corn grinders and fresh corn threshers, designed to help you handle every step of corn production with ease.

If you want to boost your productivity and reduce labor costs, please don’t hesitate to contact us for a detailed consultation and competitive pricing. We look forward to helping you find the perfect machinery solution!