Automatic multi grain thresher for corn millet sorghum soybeans

| Model | MT-860 |

| Capacity | 1.5-2T/H |

| Size | 1150*860*1160mm |

| Threshing Rate | 98% |

| Wheel | Four |

| Weight | 112kg |

| Power | gasoline engine |

The multi grain thresher machine is a versatile agricultural processing machine for threshing a wide range of cereals and legumes, including corn, millet, sorghum, and soybeans. It significantly reduces manual labor and improves harvesting efficiency by automatically separating grain kernels from husks and impurities with minimal input.

The product is available in two main models—MT-860 and MT-1200—with capacities of approximately 1.5–2 t/h and 3 t/h, respectively. Both models achieve a high threshing rate of about 98%, feature easy operation with interchangeable screens for different crops, and can be powered by gasoline or diesel engines.

Commercial multi grain thresher for sale

This commercial multi grain thresher for sale is engineered to meet the demands of diversified grain processing by integrating threshing functions for multiple crops into one compact machine.

By simply changing the internal screen, the equipment can adapt to grains with different kernel sizes, ensuring clean separation and smooth discharge during operation. For instance, when processing corn, a larger mesh screen is installed to allow kernels to pass efficiently without blockage or damage.

To suit various working conditions, the machine offers flexible power configurations, including electric motor, diesel engine, and gasoline engine options. This enables stable operation in both grid-powered areas and remote farms. During corn threshing, the machine can handle material with husks or without husks, improving adaptability and reducing pre-processing requirements.

Designed for commercial efficiency, the multi grain thresher delivers high output while minimizing labor input and energy consumption. Two models are available—MT-860 and MT-1200—each with different processing capacities and structural sizes, allowing users to select the most appropriate solution based on their production scale, crop type, and throughput expectations.

Structure of the corn thresher for sale

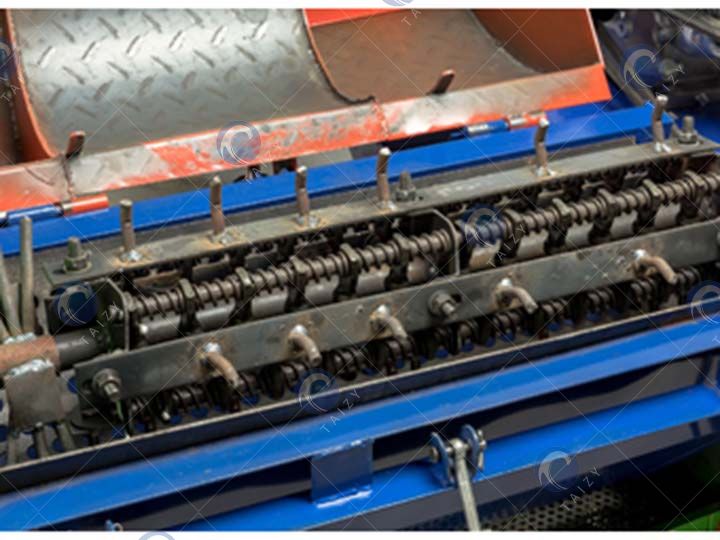

Multi grain thresher mainly includes an inlet, threshing device, draught fan, impurity outlet, light impurity export, grain export, etc.

The inner structure of the threshing device

This part includes a screen cylinder hammer. When we process different grains we should change the screen with different size of mash. And it is easy to operate.

How does the maize sheller machine work?

- Feed the grain into the multi grain thresher through the inlet.

- The grain enters the threshing chamber and is impacted by the high-speed rotating hammer cylinder, which breaks and threshes the material.

- Threshed kernels pass through the sieve holes, where kernels and residues are separated according to size.

- Clean kernels and impurities are discharged from different outlets, completing the threshing and separation process.

Technical parameters of grain thresher for sale

| Model | MT-860 | MT-1200 |

| Capacity | 1.5-2T/H | 3t /h |

| Size | 1150*860*1160mm | 2100*1700*1400mm |

| Threshing Rate | 98% | 98% |

| Wheel | Four | Six |

| Weight | 112kg | 200kg |

| Power | gasoline engine | 10-12HP diesel engine |

Advantages of motorized corn sheller

- High working efficiency: Processing capacity reaches 1.5–2 T/H or up to 3 T/H, suitable for continuous operation.

- Fully automatic operation: Once the grain is fed into the machine, threshing and impurity removal are completed automatically without manual intervention.

- Easy to operate: Simply start the multi grain thresher and feed the grain; no complex adjustments are required.

- Time- and energy-saving: The entire process can be handled by one operator, with much higher efficiency than traditional manual threshing.

- Multi-purpose application: One machine is capable of threshing four different grains, including corn, millet, sorghum, and soybeans.

- Clean finished output: The machine effectively separates kernels from impurities, ensuring a clear and high-quality final product.

FAQs about the multi grain thresher

How to thresh different crops?

To adjust the machine for different grains, simply open the top lid and replace the screen according to the kernel size. When threshing corn, the four internal shafts should be removed to better accommodate the larger kernels and ensure smooth, efficient operation.

Is it easy to move?

Wheel + push handle, easy to move.

Which crops can multi grain thresher be used for?

Corn, wheat, soybeans, sorghum, etc.

Motivation?

2.2-3kw motor, 6-8Hp diesel engine, 170F gasoline engine.

Yield, threshing rate?

1.5-2t/h; 98%

Industrial sorghum thresher sold to Burkina Faso

Last week, our sales manager received an RFQ from Alibaba and initially communicated with the customer via email, then through WhatsApp. The customer required a gasoline-powered multi grain thresher, a walking tractor, a corn planter, and a disc plow. After confirming all requirements, our salesman promptly provided a quotation.

The customer’s main concern was whether the instruction manuals were available in French. Although our manuals are usually in English, we offered French translations, which resolved the issue. As a result, the customer placed the order successfully. Below are the packing and shipping photos.

Conclusion

In summary, this multi grain thresher stands out for its high efficiency, wide crop adaptability, and stable performance. It can quickly thresh various grains such as corn, rice, and wheat, significantly reducing labor and time costs.

The machine supports a gasoline-powered option, making it suitable for different working environments, and features easy operation and convenient maintenance. In addition, we offer multilingual instruction manuals and customized services according to customer needs, ensuring smooth installation and use.

If you are looking for a reliable, practical, and cost-effective multi grain threshing solution, feel free to contact us for a quotation and detailed consultation.